Steam turbine closed loop geo-thermal cooling

a closed-loop geothermal cooling and steam turbine technology, applied in the direction of domestic cooling equipment, lighting and heating equipment, electric generator control, etc., can solve the problems of unsuitable water from many of these aquifers for consumption or irrigation, and achieve the effect of reducing the amount of water and reducing the amount of potential pollution of water systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

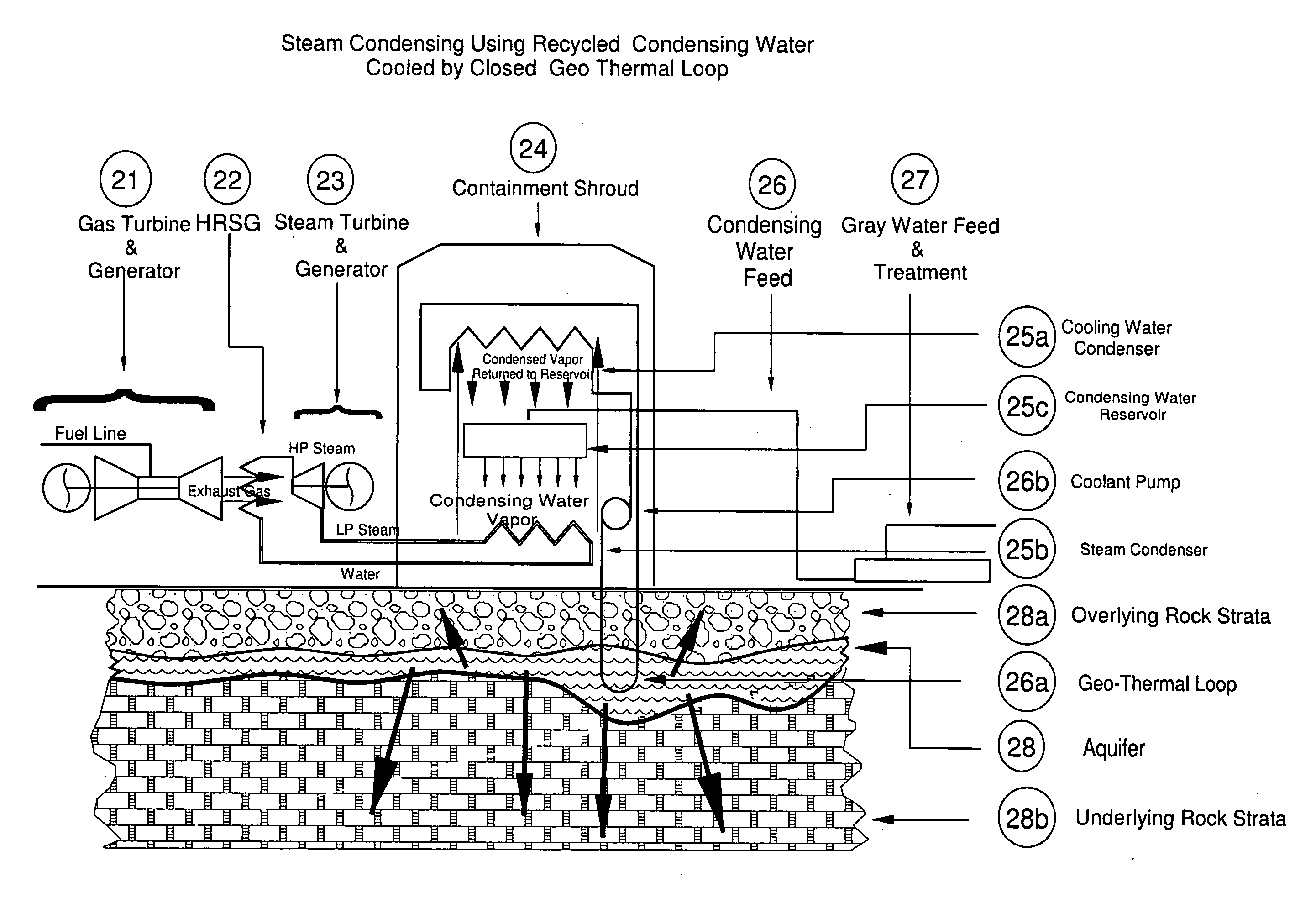

[0052]In FIG. 2 there is shown a containment shroud 24 erected over the steam condenser 25b. In some cases, a cooling tower could be converted to serve as the containment shroud. In other cases, a simple structure similar to a storage tank would serve to contain the vapor within the containment shroud. The condensing water vapor elevates through another heat exchanger the cooling water condenser 25a where it is cooled by a cooling fluid flowing through the geo-thermal loop 26a, thereby condensing the condensing water vapor to liquid, where it is recovered and returned to a cooling water reservoir 25c for reuse, together with a feed of condensing water at 26, as and when necessary.

[0053]As required, additional condensing water is added to the condensing water reservoir 25c from the condensing water feed 26 although in much smaller quantities than with conventional re-circulating technology. Although it is shown that the primary source of condensing water will be from a gray water sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com