Brush-like Grindstone

a brush-like, grinding stone technology, applied in the direction of flexible wheel, grinding machine components, manufacturing tools, etc., can solve the problems of inferior grinding capacity, low hardness, inefficient grinding, etc., and achieve the effect of preventing breakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

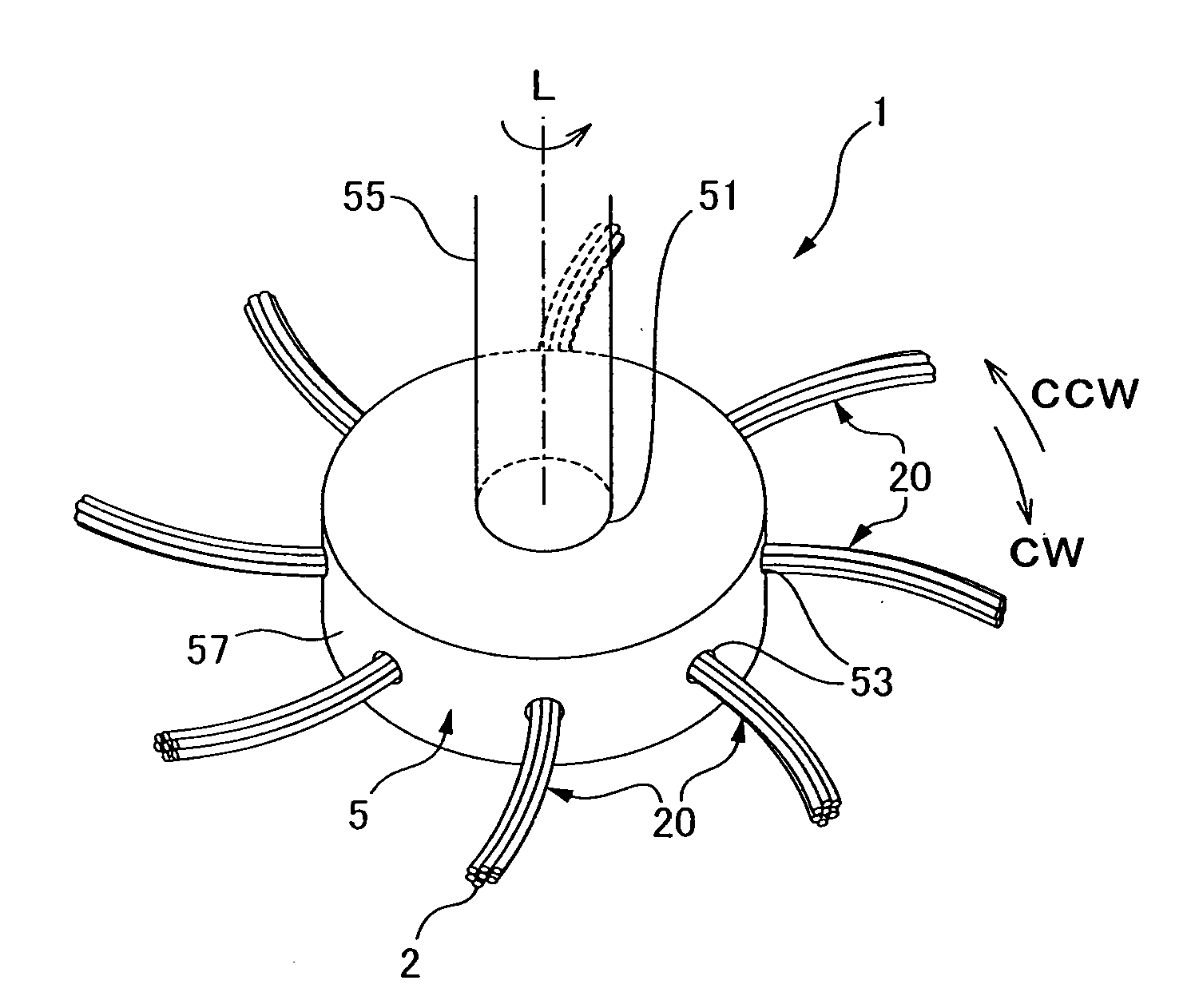

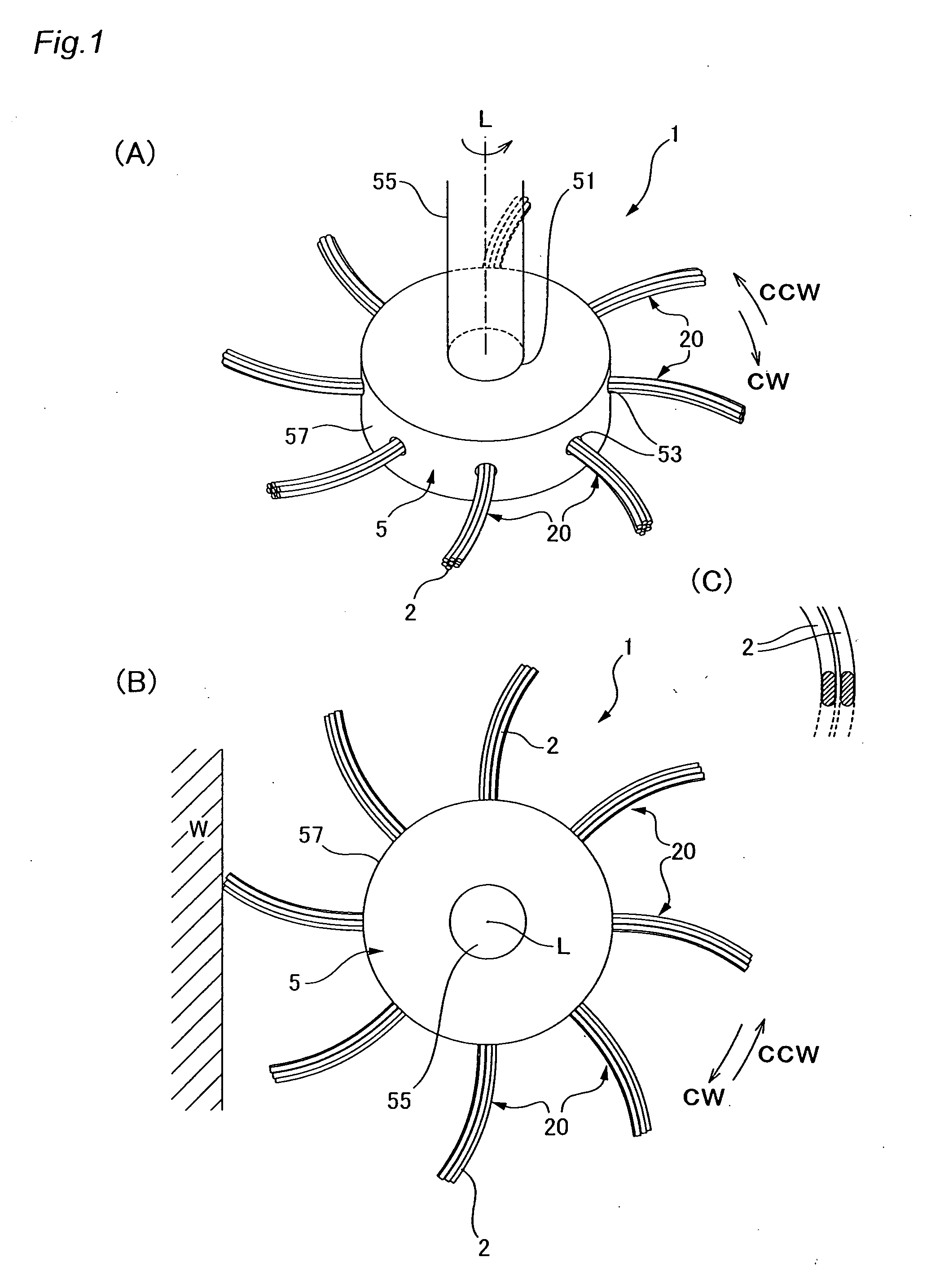

embodiment 1

Modification of Embodiment 1

[0056]Embodiment 1 described above has a configuration in which the plurality of linear grinding materials 2 are held in a holder 5 as a plurality of grinding material bundles 20, but a configuration may also be utilized in which a circumferential groove is formed in a outer peripheral side surface 57 of the holder 5, and the plurality of linear grinding materials 2 are held across the entire circumferential length of this circumferential groove.

Embodiment 2

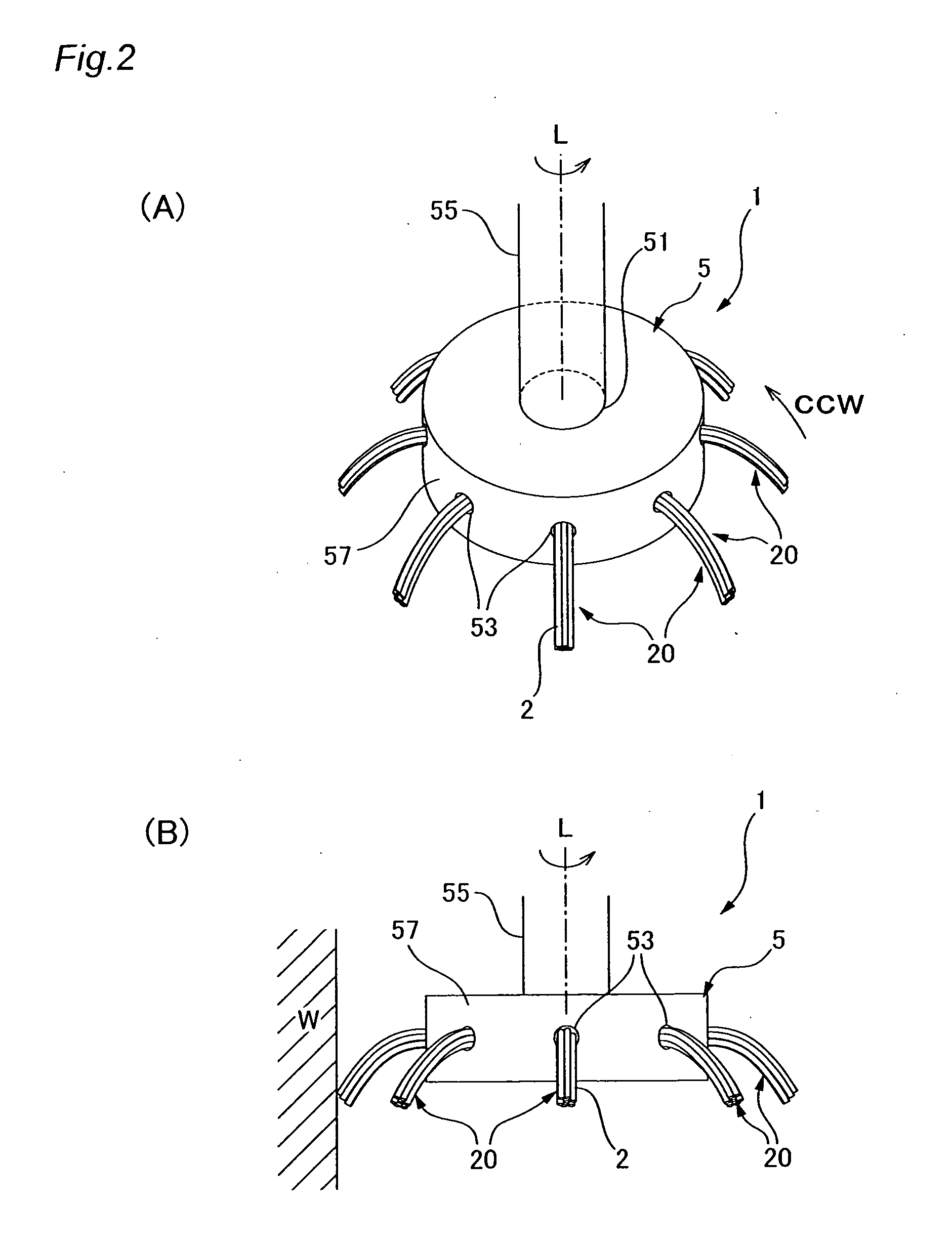

[0057]FIGS. 2(A) and (B) are a perspective view and a side view of the brush-like grindstone of embodiment 2 of the present invention. With this embodiment and embodiments 3 to 8 below, the basic configuration is the same as in embodiment 1, and the descriptions thus employ the same symbols for parts having the same function. The brush-like grindstone 1 shown in FIGS. 2(A) and 2(B) also has a configuration that is similar to that of embodiment 1, in which bundles of long alumina fibers (long inorganic ...

embodiment 2

Modification of Embodiment 2

[0062]Embodiment 2 described above has a configuration in which the plurality of linear grinding materials 2 are held in a holder 5 as a plurality of grinding material bundles 20, but a configuration may also be employed in which a circumferential groove is formed in the outer peripheral side surface 57 of the holder 5, and a plurality of linear grinding materials 2 are held across the entire circumferential length of this circumferential groove.

Embodiment 3

[0063]FIGS. 3(A) and 3(B) are perspective and side views of the brush-like grindstone of Embodiment 3 of the present invention. The brush-like grindstone 1 in FIGS. 3(A) and 3(B), as with Embodiments 1 and 2, has a configuration in which fiber bundles of long aluminum fibers (long inorganic fibers) are impregnated with a resin, which is then caused to harden to produce linear grinding materials 2, a plurality of which are held in a metal holder 5. The holder 5 is a cylinder with a shaft hole 51 that pa...

embodiment 3

Modification of Embodiment 3

[0068]Embodiment 3 described above has a configuration in which the plurality of linear grinding materials 2 are held in a holder 5 as a plurality of grinding material bundles 20, but a configuration may also be employed in which a circumferential groove is formed in the outer peripheral side surface 57 of the holder 5, and a plurality of linear grinding materials 2 are held across the entire circumferential length of this circumferential groove.

Embodiment 4

[0069]FIGS. 4(A) and 4(B) are a perspective view and plan view of a brush-like grindstone of Embodiment 4 of the present invention. The brush-like grindstone 1 shown in FIGS. 4(A) and 4(B), as in Embodiment 1, has a configuration in which bundles of long alumina fibers (long inorganic fibers) are impregnated with a resin, which is caused to harden to produce linear grinding materials 2, a plurality of which are held in a metal holder 5. The holder 5 is cylindrical with a shaft hole 51 that is formed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com