Fabricated Turbine Housing

a turbine and housing technology, applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of reducing the power affecting and the traditional turbine housing suffers from several deficiencies, so as to reduce the power of the turbine, and improve the efficiency of the turbocharger system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Reference will now be made in detail to exemplary embodiments of the present invention, examples of which are illustrated in the accompanying drawings. It is to be understood that other embodiments may be utilized and structural and functional changes may be made without departing from the respective scope of the present invention.

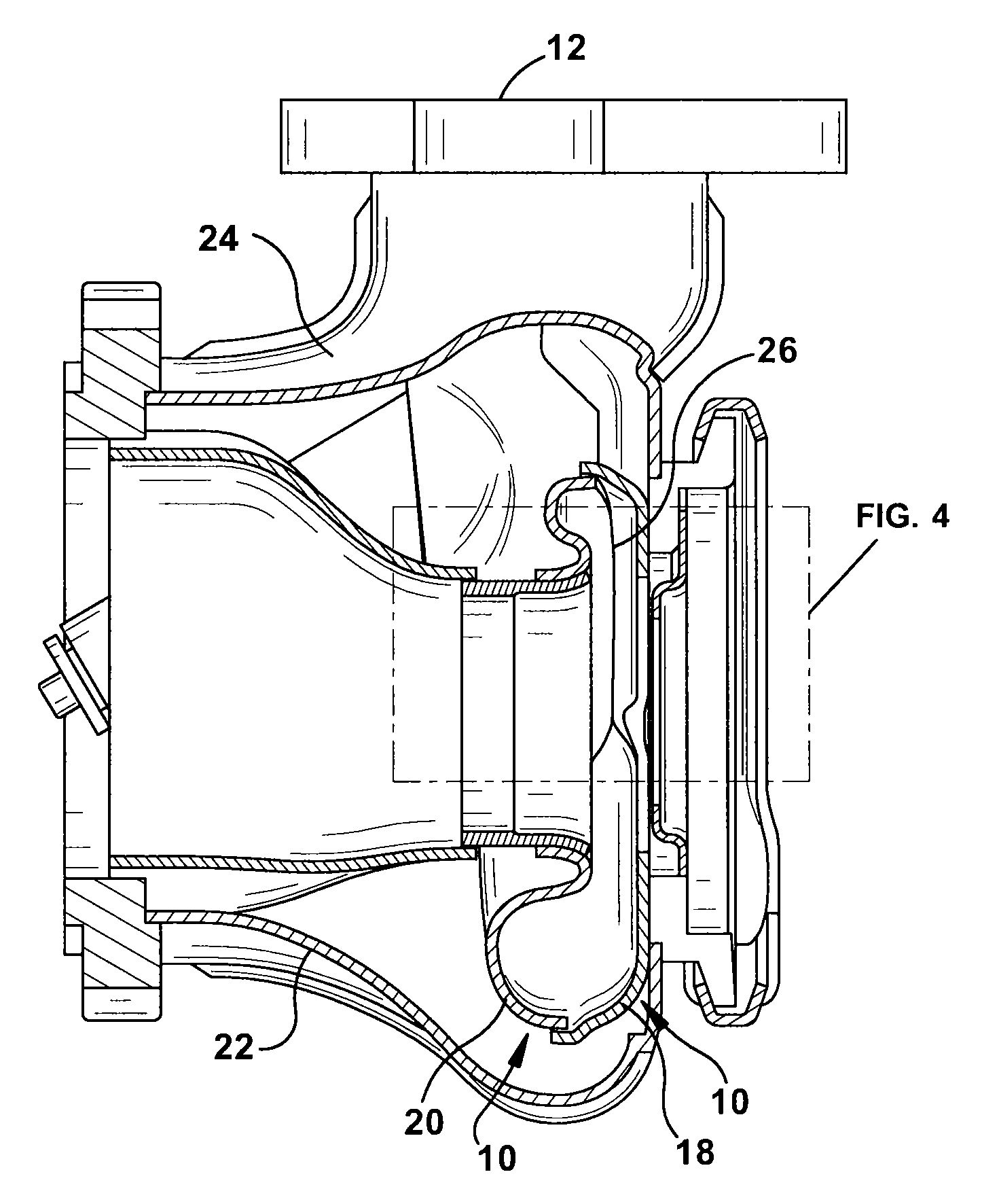

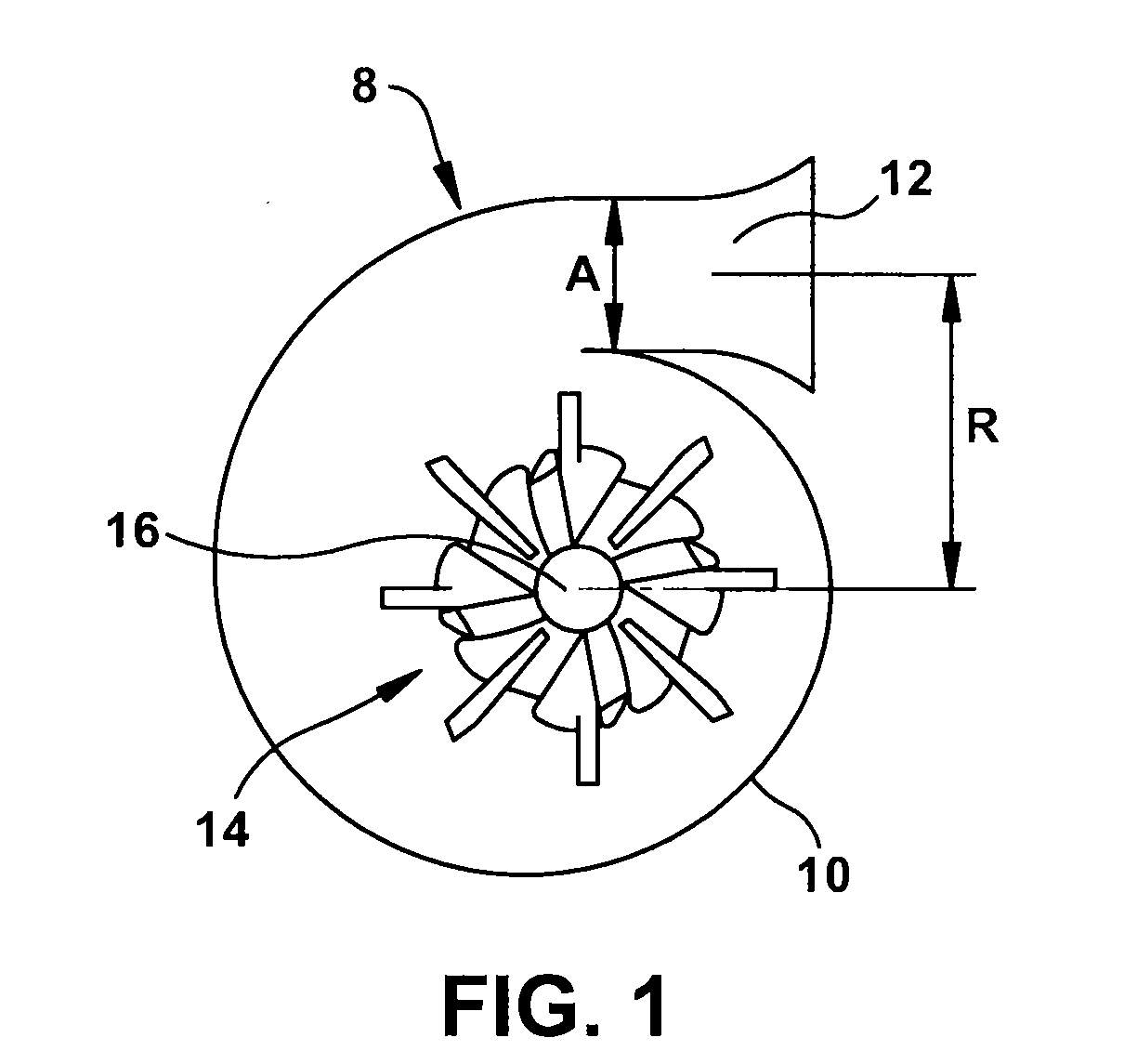

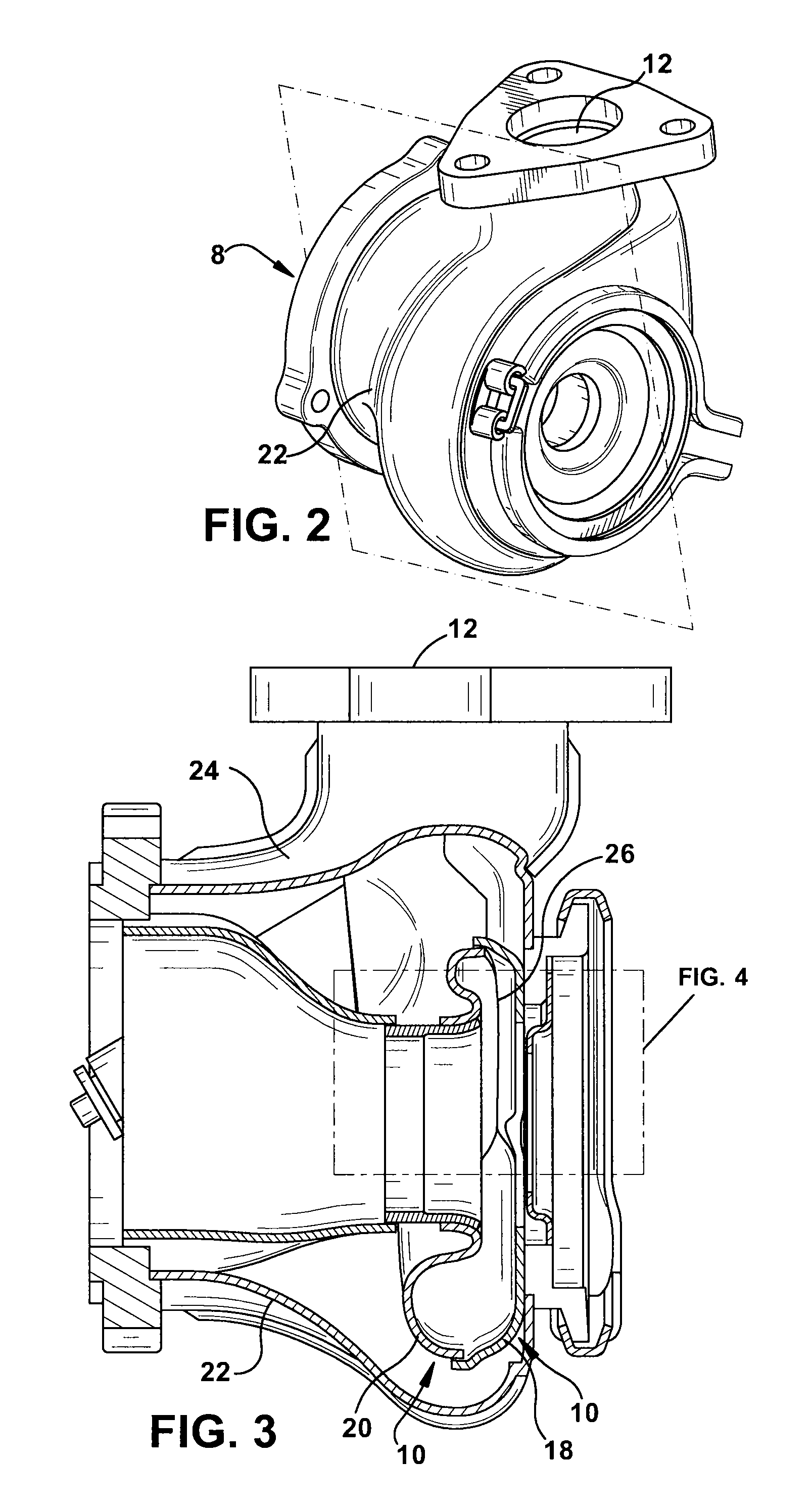

[0024]The efficiency of the power generated by a turbocharged engine may depend on the efficiency in which a turbine housing manages and channels the flow of the engine's exhaust through the turbine housing. FIG. 1 is a schematic illustration of a turbine housing 8. The turbine housing 8 includes a generally volute-shaped inner housing 10 and an inlet 12 at the opening of the inner housing 10. The volute shape and the position of the inlet 12 promote rotational flow within the inner housing 10. Such rotational flow spins a turbine 14 positioned generally in the center of the inner housing 10. As will be understood, as exhaust gases flow along the per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com