Co-processing diesel fuel with vegetable oil to generate a low cloud point hybrid diesel biofuel

a technology of hybrid diesel and diesel fuel, which is applied in the field of diesel fuel, can solve the problems of poor low-temperature properties of conventional ester-based biodiesel, and achieve the effect of reducing the cost of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

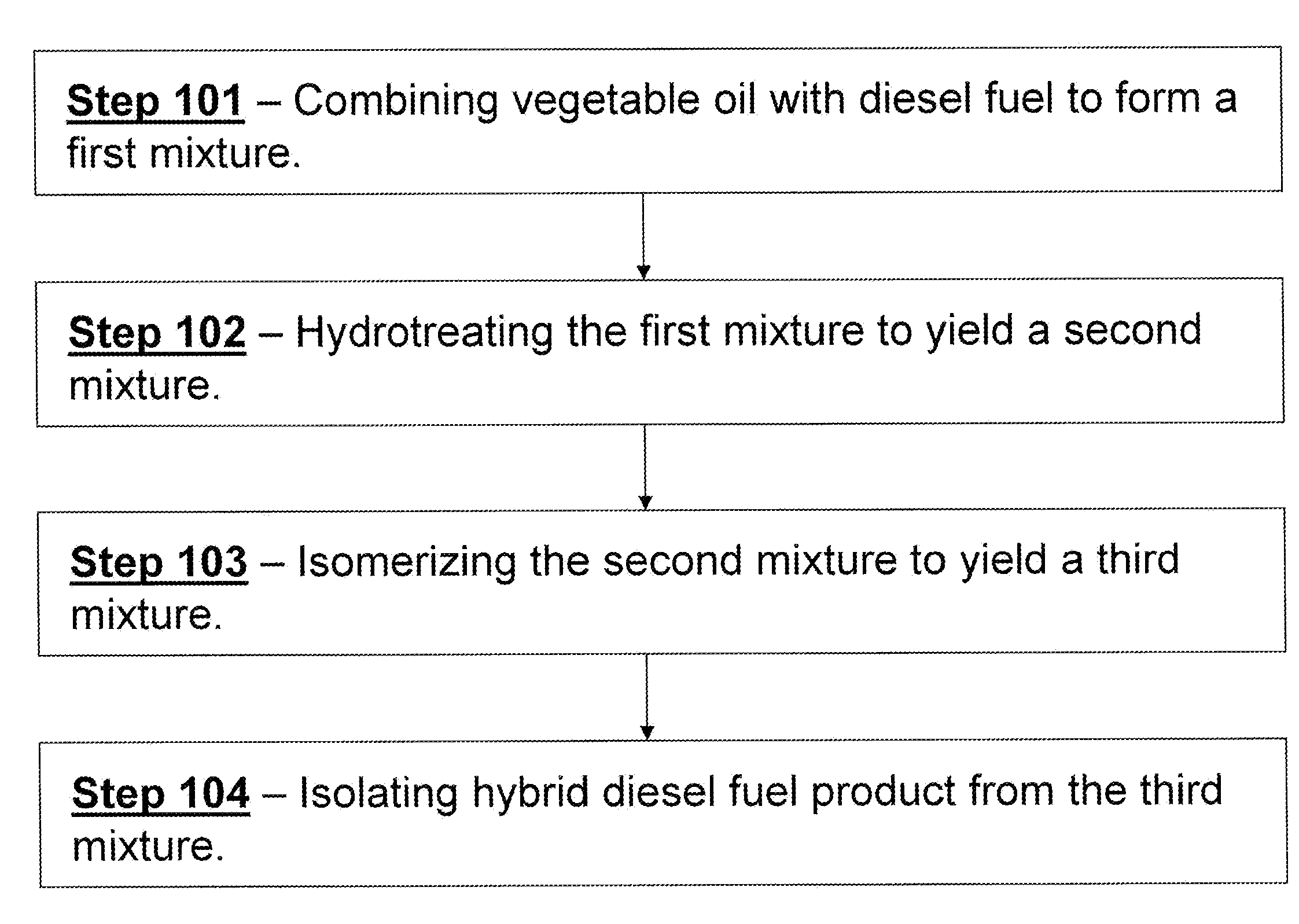

Method used

Image

Examples

example

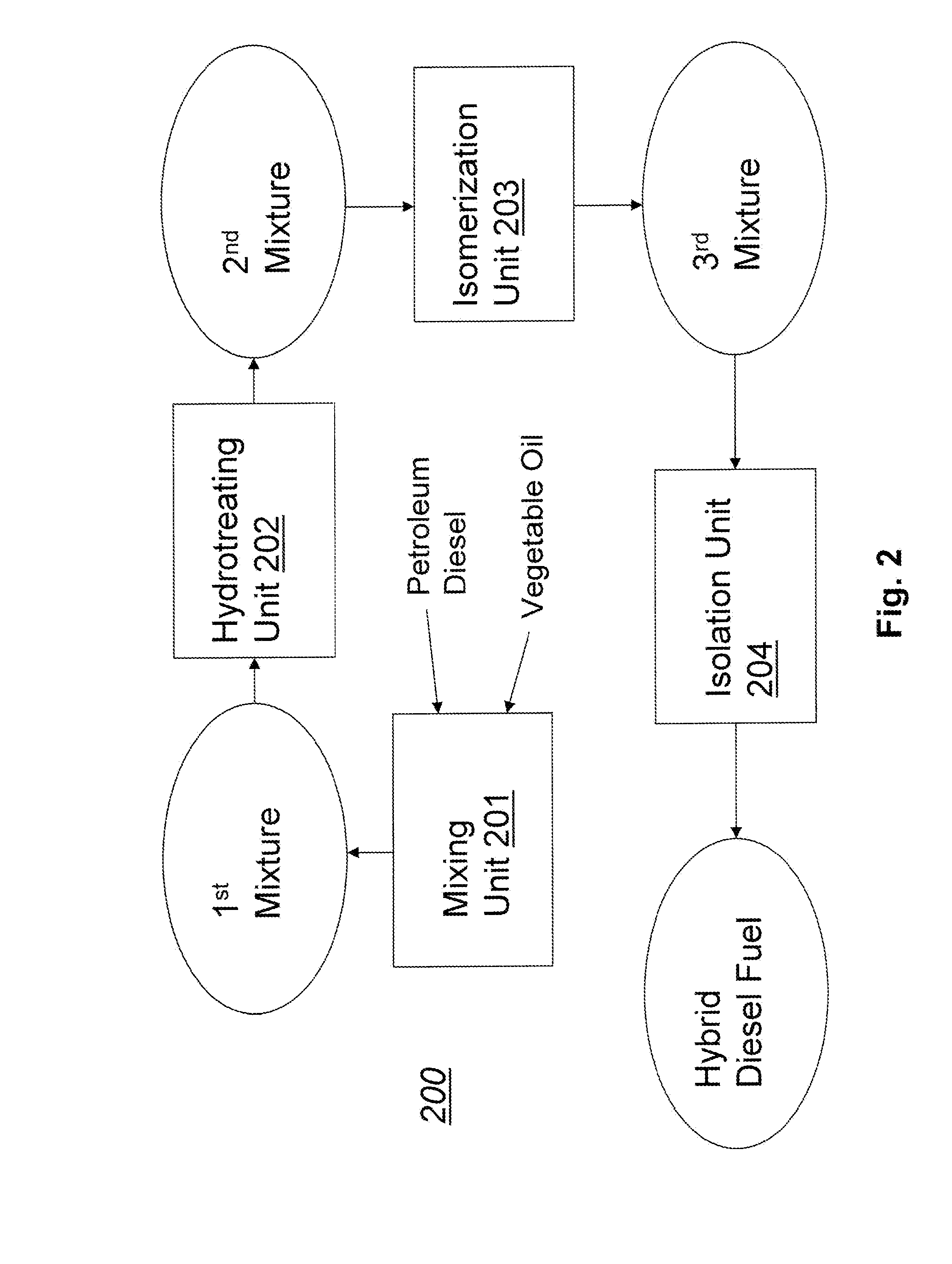

[0057]This Example serves to illustrate an exemplary system for implementing a method embodiment of the present invention, so as to produce a hybrid diesel biofuel.

[0058]Using for isomerization a catalyst of Pt on SM-7, a 95 / 5 diesel / canola oil mixture, having approximately 500 ppm sulfur (S), was hydroprocessed (hydrodesulfurization, HDS) in a hydrotreating unit to yield a hybrid diesel intermediate. Note that, upon hydrotreating, diesel processed Without canola oil is much reduced in sulfur content (below 6 ppm), but has a relatively high cloud point (i.e., −7° C.; see Table 1, vide infra). With canola oil added, this hybrid diesel intermediate mixture was processed in an isomerization unit employing an ISODEWAXING (IDW) catalyst (Pt on SM-7) to yield a hybrid diesel product having a relatively low cloud point (−13° C.). This lower cloud point allows the diesel to be used in colder climates. No interstage removal of H2S and NH3 was required, with the total effluent from the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com