System and method for carrying out an inspection or maintenance operation with compliance tracking using a handheld device

a handheld device and inspection or maintenance technology, applied in the field of inspection systems, can solve problems such as the size of construction projects, the increase in the number of crane-related deaths, and the fatalities of assembly/disassembly accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

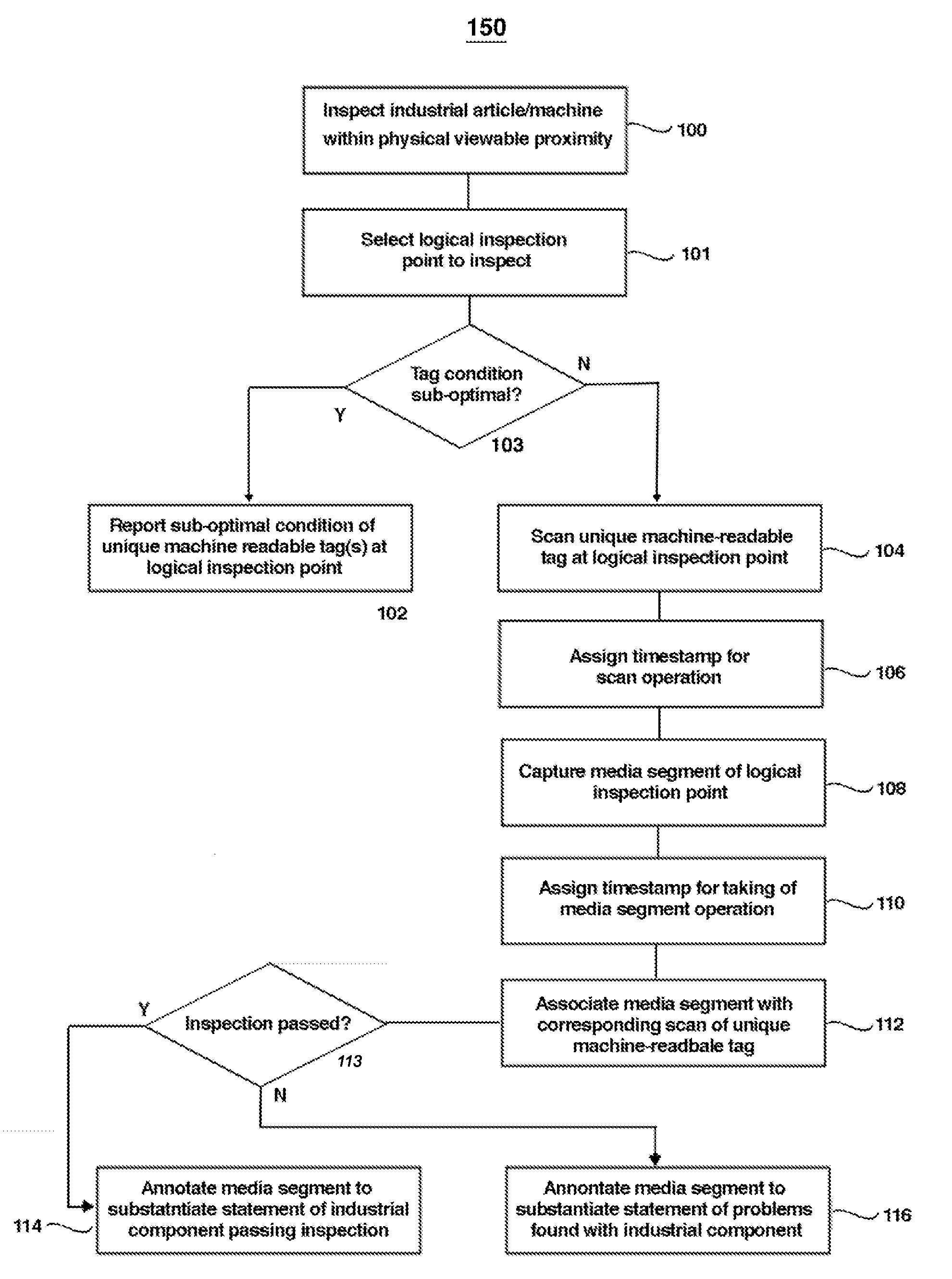

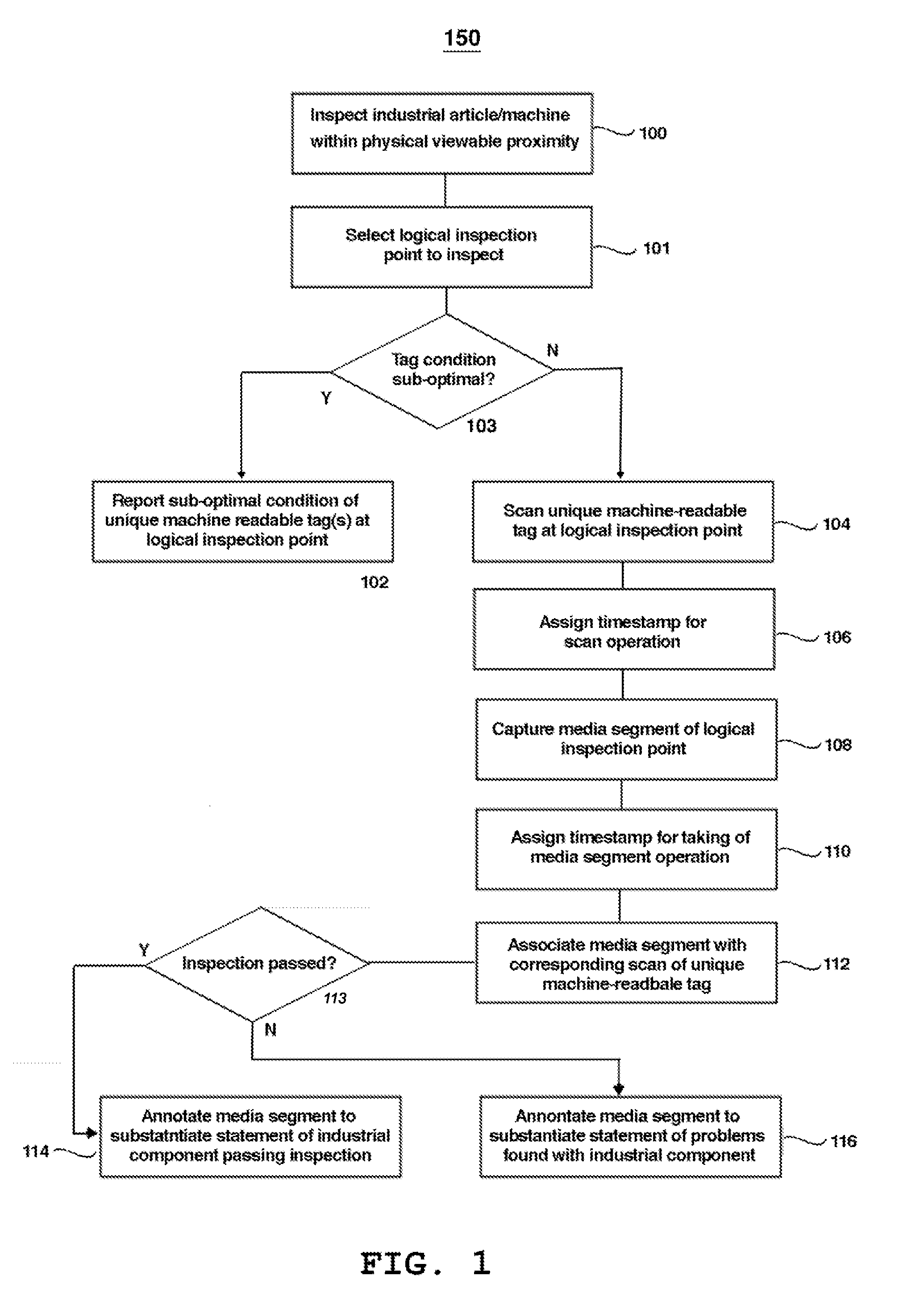

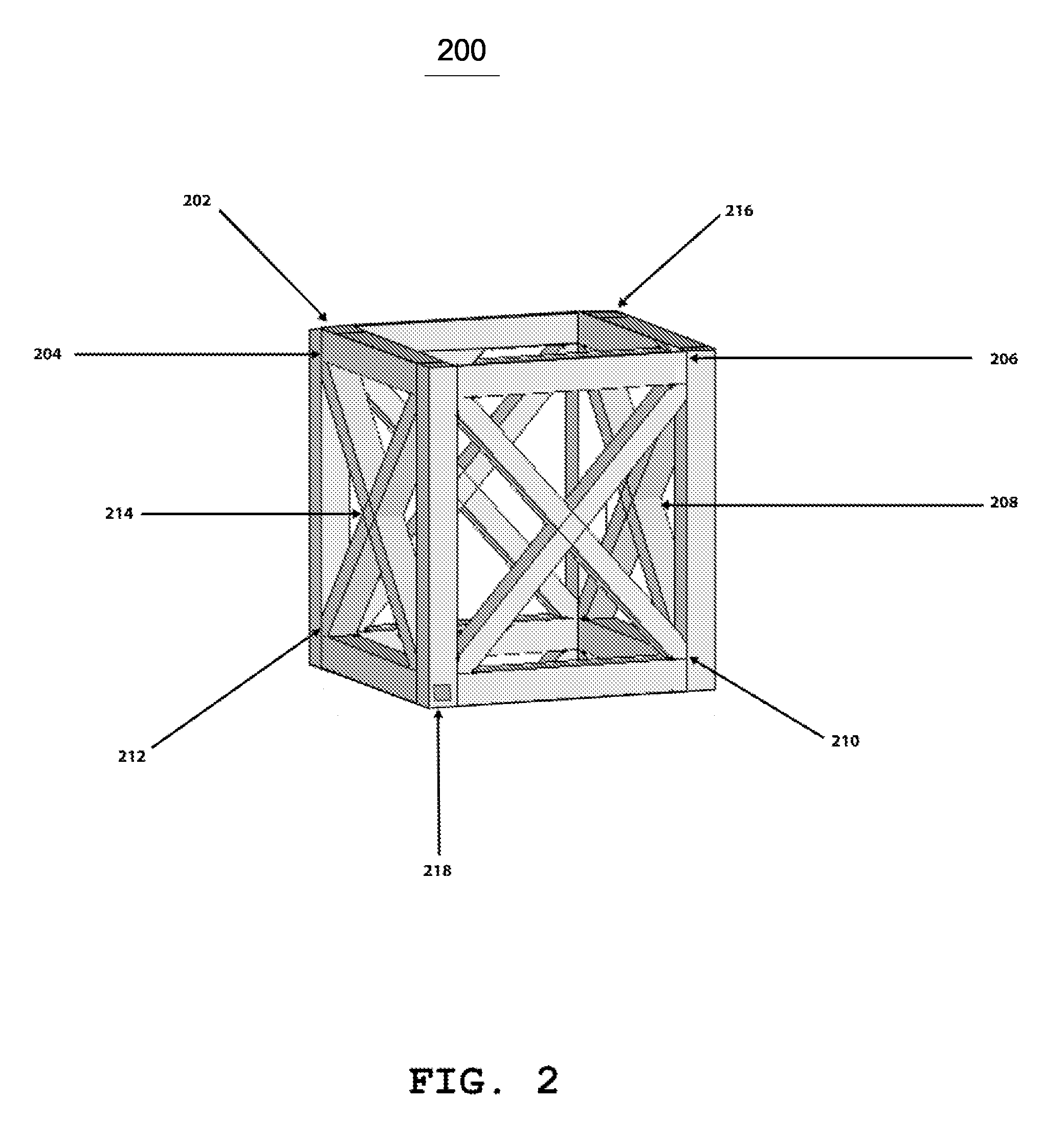

[0041]The invention generally pertains to an industrial inspection compliance system with which various methods can be carried out to the effect of assisting in an inspection and providing the means for compliance verification of a proper inspection. For the purposes of the text describing this invention, an inspection may represent the process of checking a physical component for safety, security or business reasons, doing the same for compliance with industry standards and guidelines, or a maintenance operation on a physical component for those same reasons. These methods can generally be best executed by a multi-function handheld device, carried to and used in the physical proximity of an inspection component by the inspector. Examples of multi-function handheld devices include the Apple iPhone®, the Psion Teklogix Workabout Pro®, the Motorola MC-75®, and the like, but the present invention is not limited to such devices as shown or described here. One aspect of the invention rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com