Multifunctional antistatic non-woven fabric and fabrication method thereof

a technology of non-woven fabric and fabrication method, which is applied in the direction of weaving, non-metal conductors, conductors, etc., can solve the problems of insufficient anti-static

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

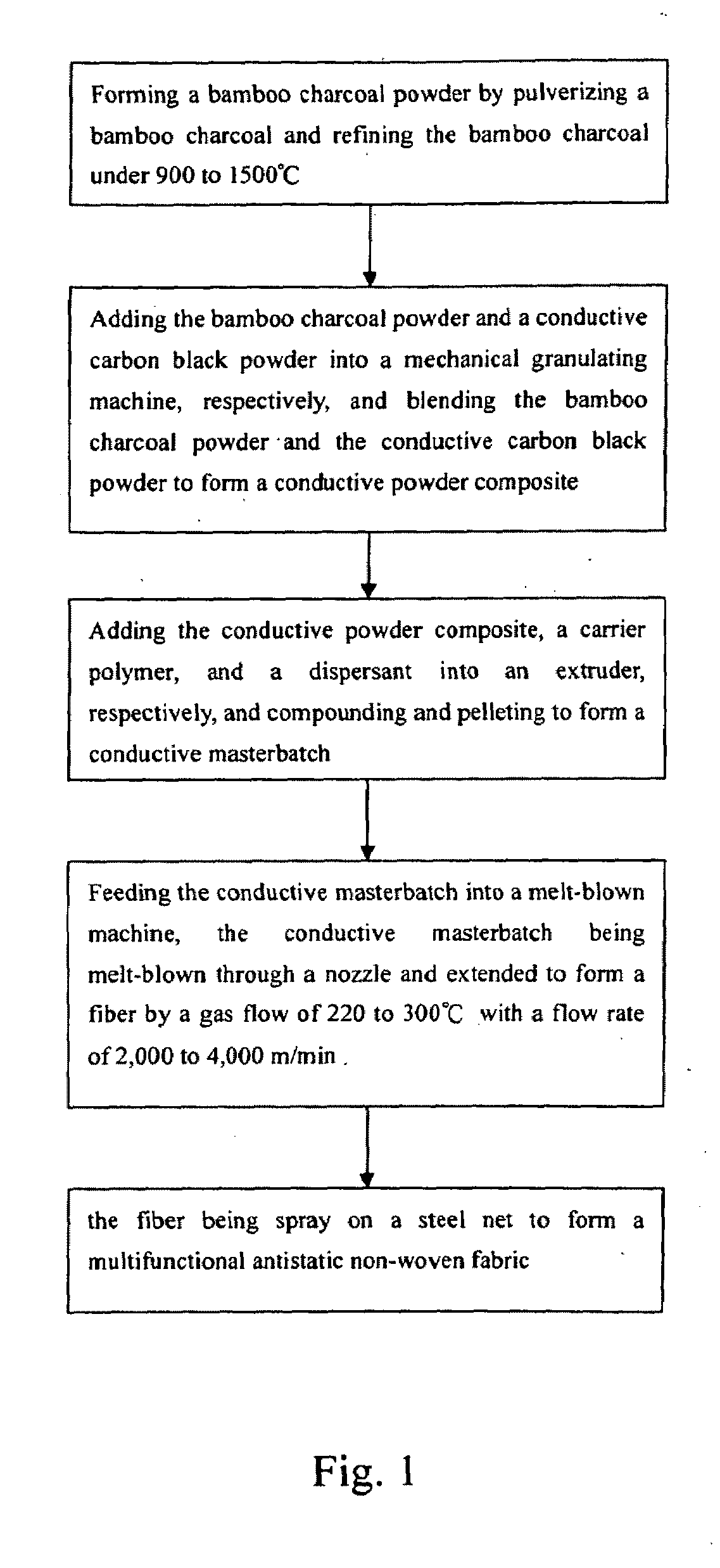

Method used

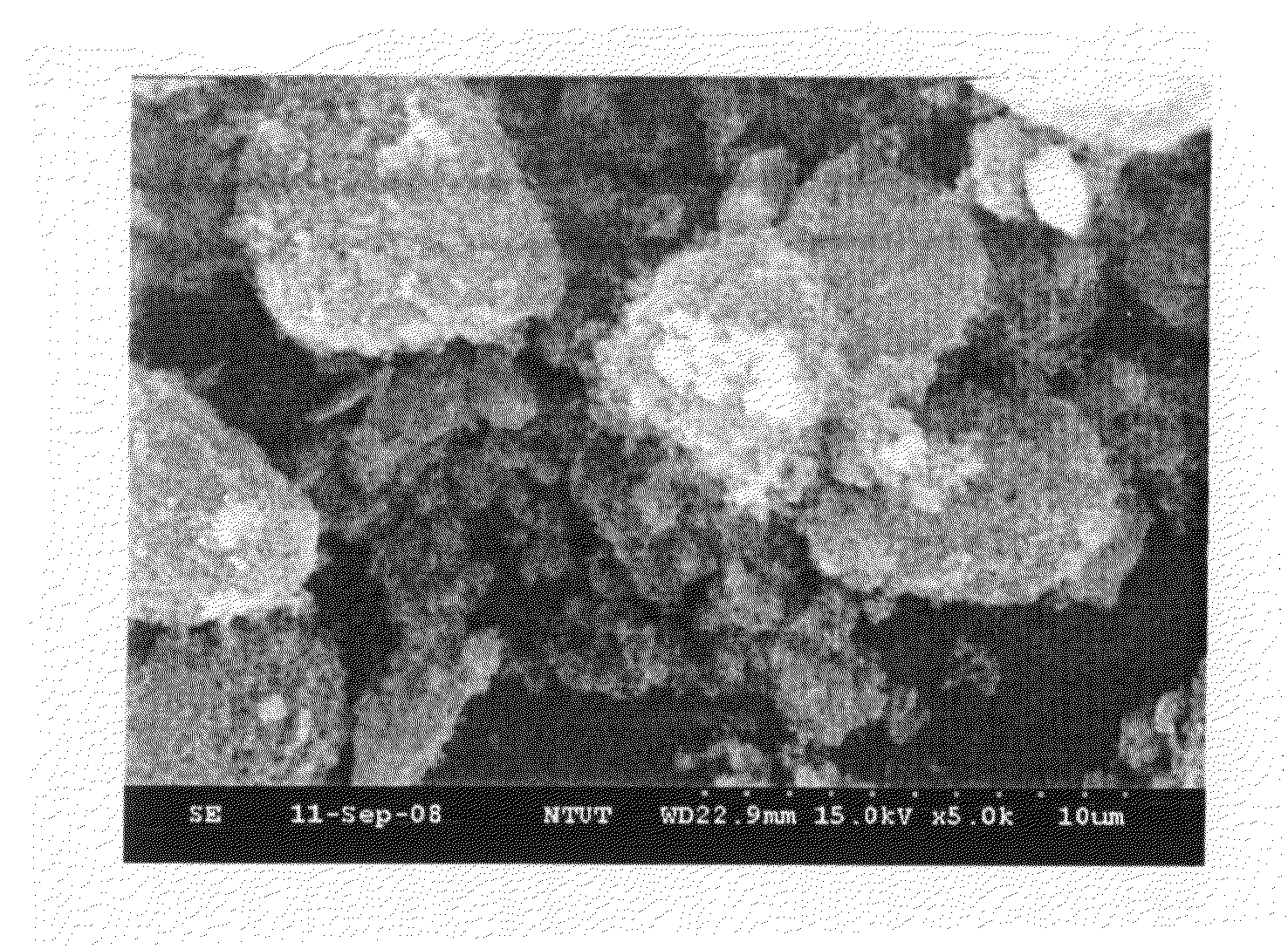

Image

Examples

example 1

[0046]100 parts of the conductive carbon black powder were added into a mechanical granulating machine (commercial equipment AMS-LAB made by the HOSOKAWA company). The conductive carbon black powder was blended for about 5 minutes in the mechanical granulating machine with the operation parameters of 2.2 kW of power and 2480 rpm of rotation speed, to form the conductive powder composite of Example 1.

example 2

[0047]75 parts of the conductive carbon black powder and 25 parts of the bamboo charcoal powder were added into a mechanical granulating machine (commercial equipment AMS-LAB made by the HOSOKAWA company), respectively. The bamboo charcoal powder and the conductive carbon black powder were blended for about 5 minutes in the mechanical granulating machine with the operation parameters of 2.2 kW of power and 2480 rpm of rotation speed, to form the conductive powder composite of Example 2.

example 3

[0048]50 parts of the conductive carbon black powder and 50 parts of the bamboo charcoal powder were added into a mechanical granulating machine (commercial equipment AMS-LAB made by the HOSOKAWA company), respectively. The bamboo charcoal powder and the conductive carbon black powder were blended for about 5 minutes in the mechanical granulating machine with the operation parameters of 2.2 kW of power and 2480 rpm of rotation speed, to form the conductive powder composite of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com