Method for Producing Hot Water Utilizing Combined Heat Resources of Solar Energy and Heat Pump in the Manner of Heating Water at Multilpe Stages and Accumulating Energy and a Device Especially for Carrying Out the Method

a technology of solar energy and heat pump, which is applied in the field of solar energy, can solve the problems of low solar radiant energy, low energy-flux density, and inability to meet the needs of the user, and achieve the effect of improving the efficiency of the collector, facilitating the use of off-peak electricity, and facilitating the collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

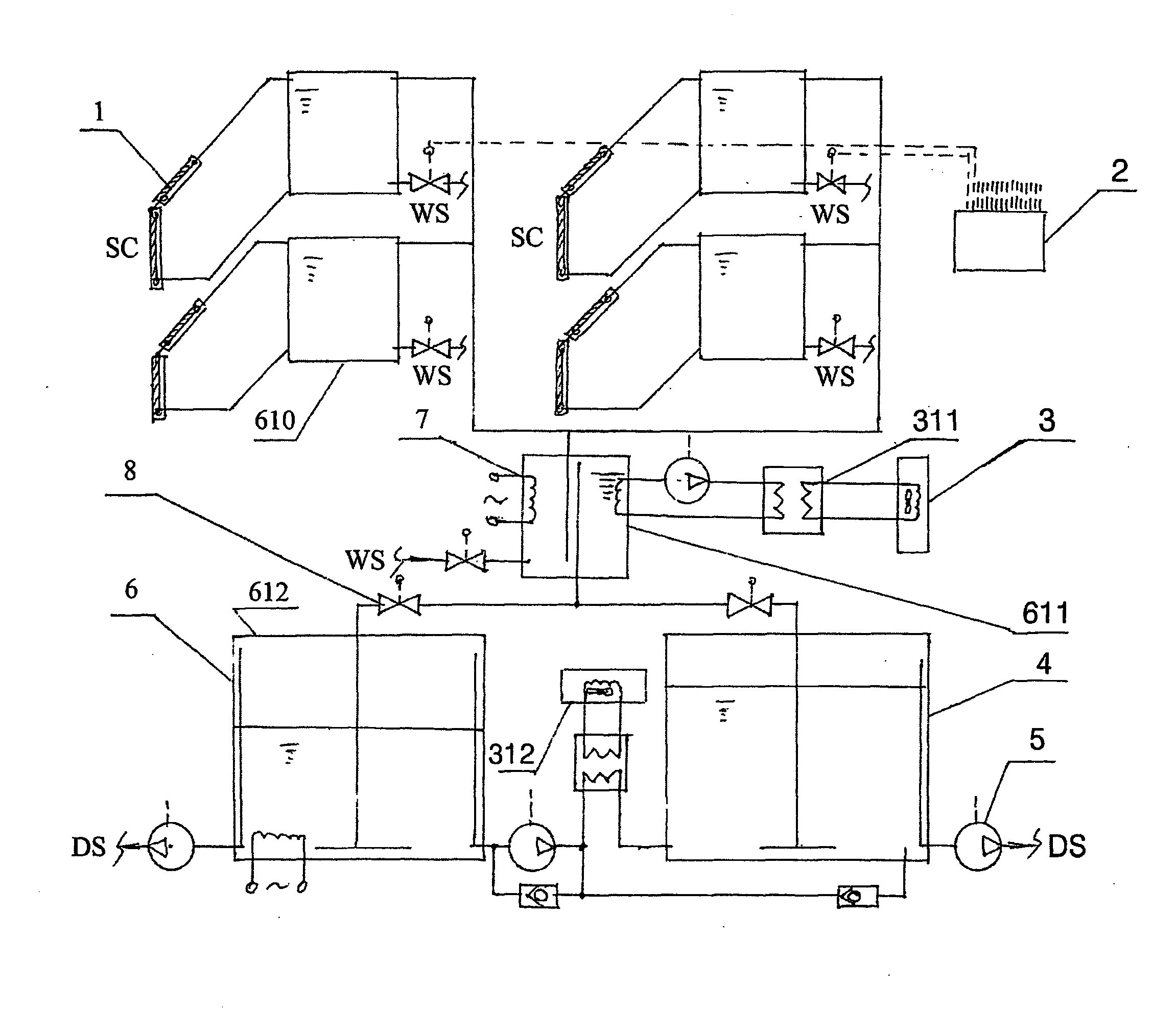

[0024]FIG. 1 is a schematic structural view of a device according to the present invention, which includes at least one solar energy collector 1, a control unit 2, at least one heat pump 3, at least one water tank 4, at least one booster pump 5, at least one water-heating tank 6, at least one electrical heater 7, and at least one electric control valve 8.

[0025]The water-heating tank 6 is a water tank for heating at multiple stages formed by two or more multi-stage heating water tanks 611 and 612. The multi-stage heating water tank 611 is a conflux hot water tank of multi-stage heating, and the multi-stage heating water tank 612 is a warm water storage tank of multi-stage heating. The multi-stage heating water tank 611 includes circulating water-heating tank for the collector of multi-stage heating 610 and the conflux hot water tank of multi-stage heating 611. The hot water tanks of multi-stage heating 611 and 612 are mounted in front of the final temperature water storage tank 4. Th...

second embodiment

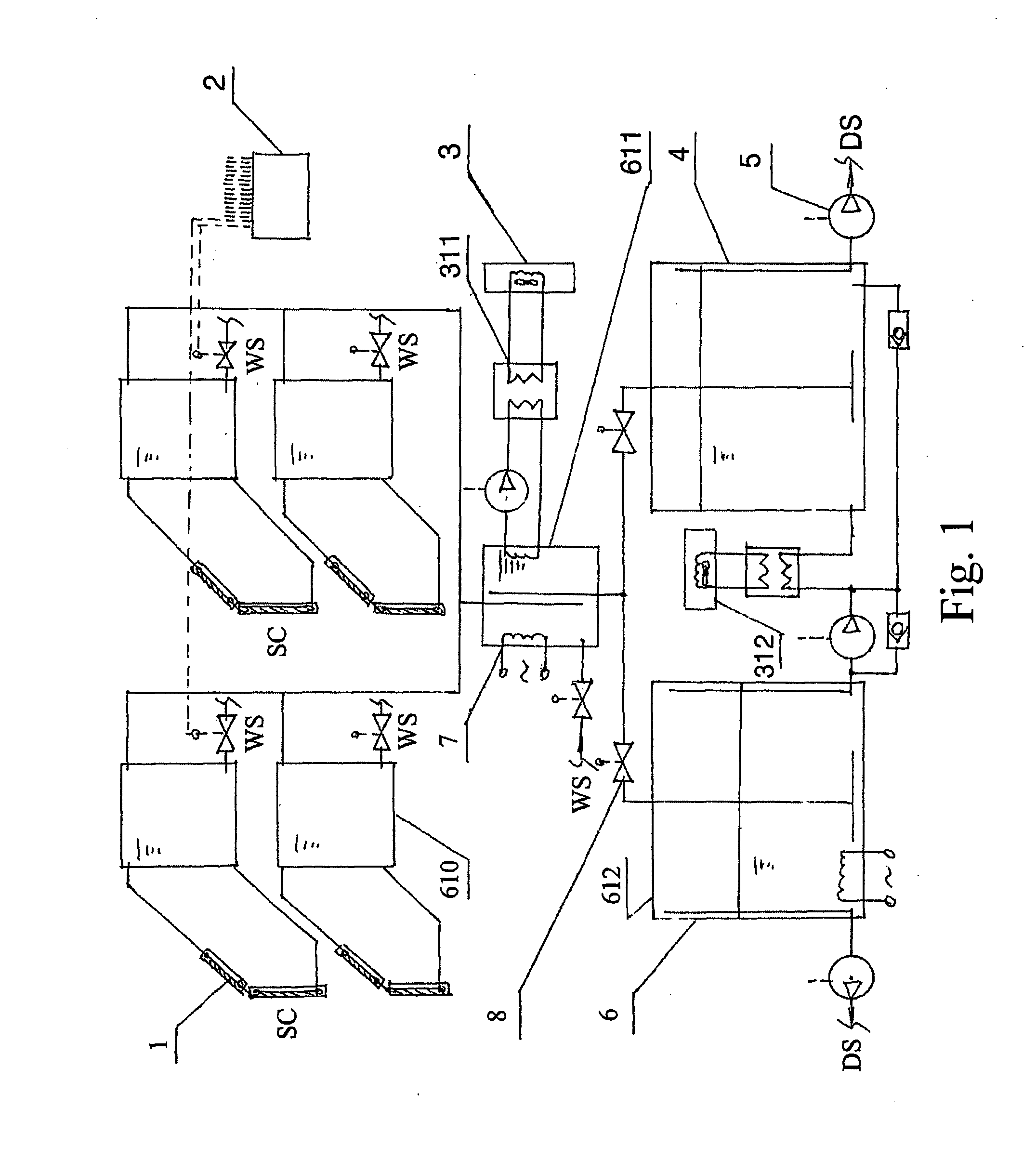

[0033]FIG. 2 is a schematic structural view of a device according to the present invention, which includes at least one solar energy collector 1, a control unit 2, at least one heat pump 3, a final temperature water storage tank 4, a booster pump 5, at least one water-heating tank 6, at least one electrical heating element 7, and at least one electric control valve 8. In FIG. 2, multi-stage heating units of different temperatures are formed between the solar energy collector 1 and the heat pump 3, and meanwhile, two multi-stage heating outputs formed by the multi-stage heating units of the solar energy collector are connected to corresponding multi-stage heating water tanks 610 and 611 via pipelines.

[0034]The multi-stage heating water tank includes the electrical heating element 7. The multi-stage heating outputs formed by the multi-stage heating units of different temperatures constituted by the solar energy collector and the heat pump are connected to the corresponding multi-stage...

third embodiment

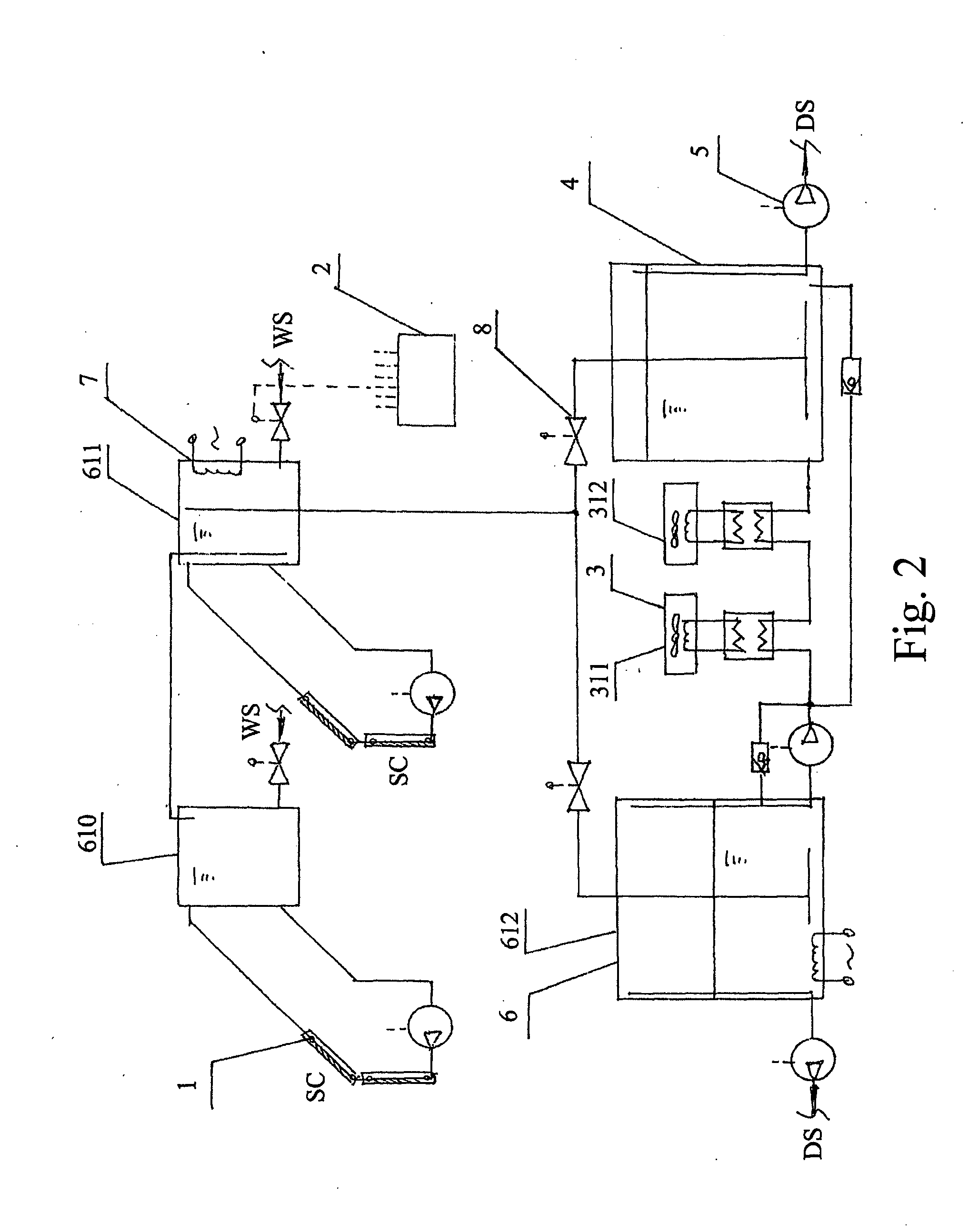

[0039]FIG. 3 is a schematic structural view of a device according to the present invention, which includes a solar energy collector 1, a control element 2, at least one heat pump 3, a final temperature water storage tank 4, a booster pump 5, at least one heating water tank 6, and at least one electrical heating element 7. In FIG. 3, the solar energy collector 1 and the heat pump 3 can form multi-stage heating units of different temperatures. The multi-stage heating outputs formed by the multi-stage heating units for the solar energy collector and the heat pump are connected to corresponding multi-stage heating water tank 6 via pipelines. The multi-stage heating water tank can include an electrical heating element 7. The solar energy collector, the water tank, the water pump, the water-heating tank, the heat pump, and the electrical heater are electrically connected to the control unit 2 respectively. A predetermined amount of produced hot water is heated at multiple stages and be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com