Plasma processing apparatus and plasma processing method

a processing apparatus and plasma technology, applied in the direction of electrical apparatus, electrical discharge tubes, basic electric elements, etc., can solve the problems of excessive fluctuation of plasma state, and deterioration of plasma stabilization, so as to improve plasma stabilization, improve plasma stabilization, and stable plasma process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

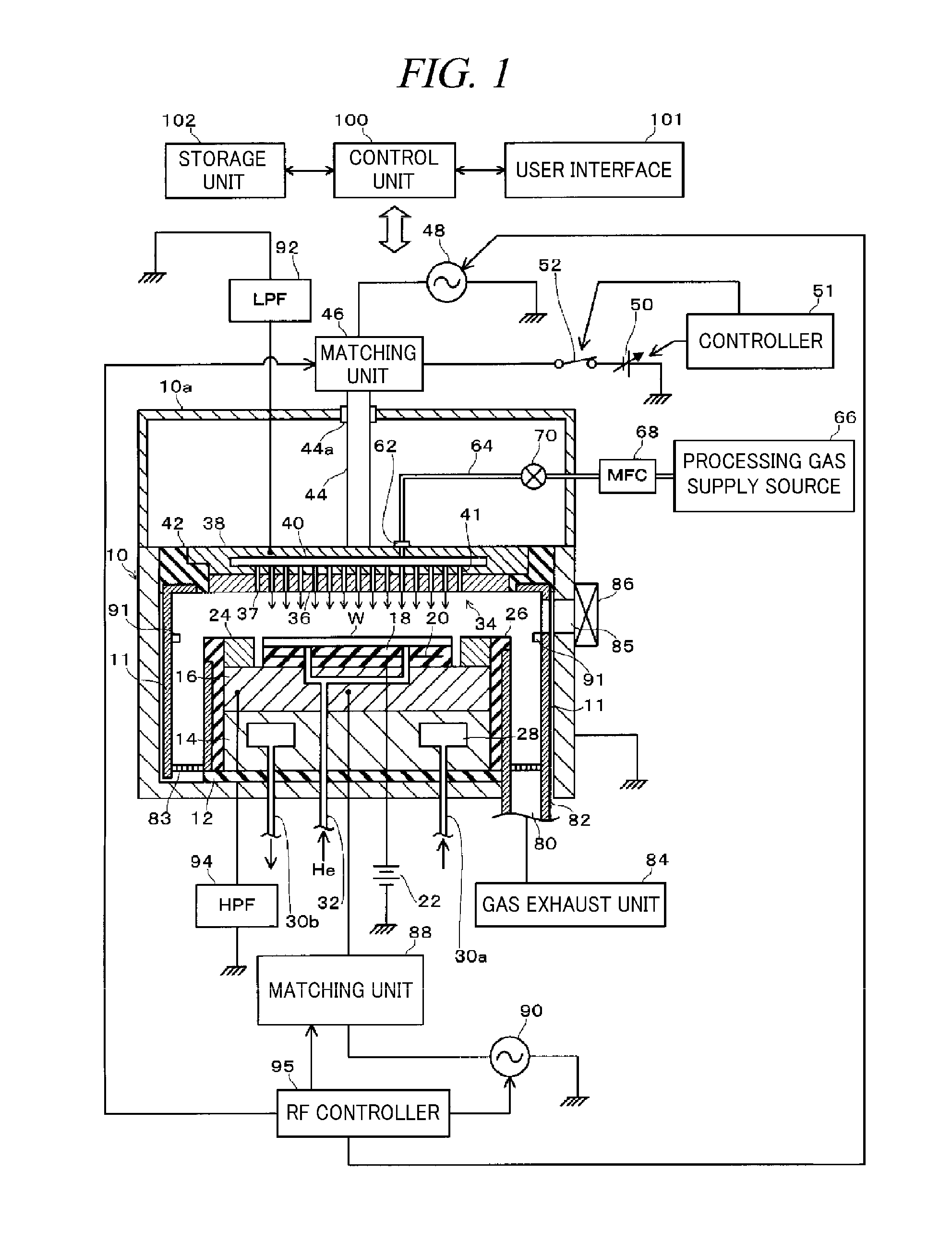

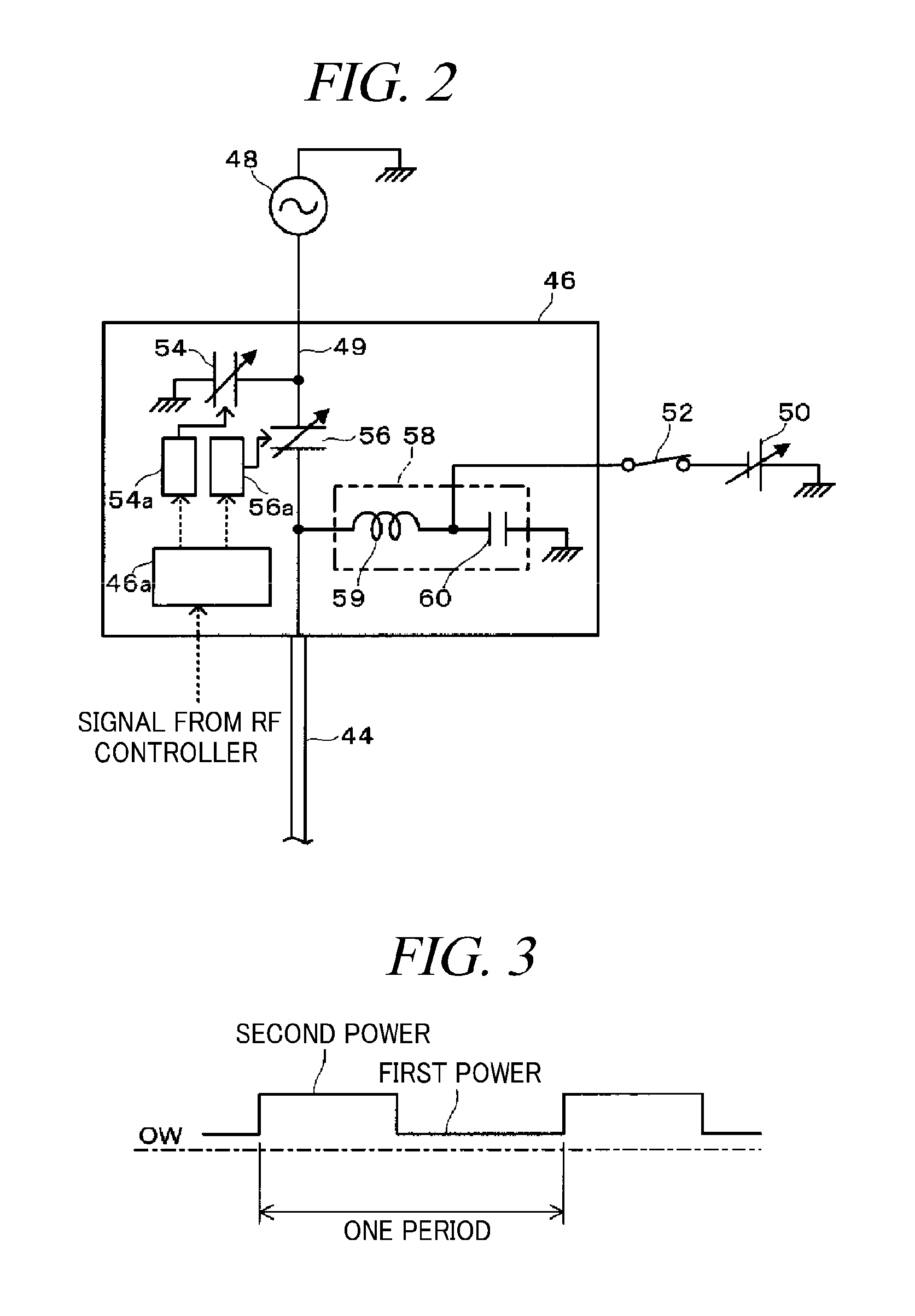

first embodiment

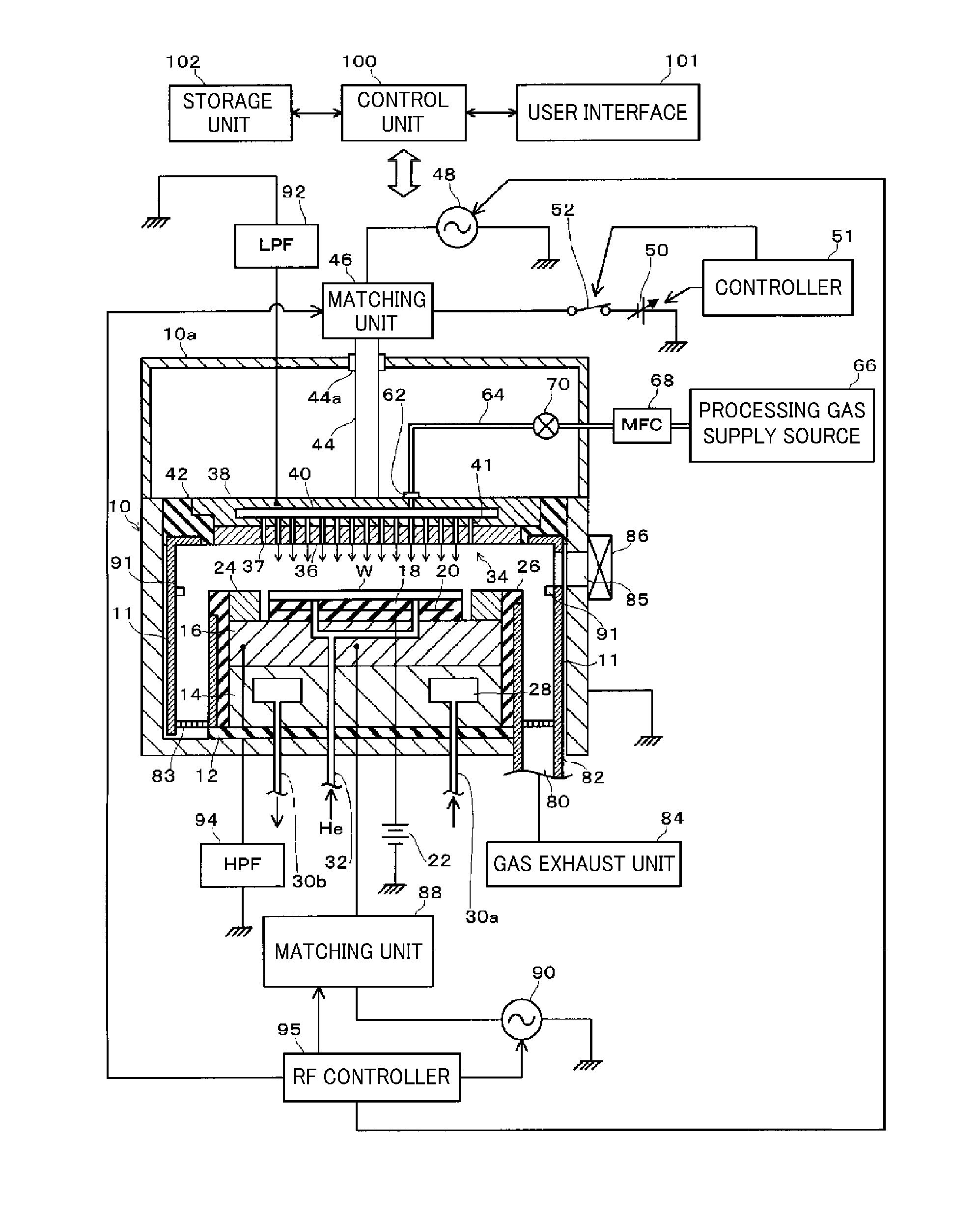

[0094]This plasma etching apparatus is different from the plasma etching apparatus in the first embodiment shown in FIG. 1 in that a high frequency power for plasma generation from a first high frequency power supply 48 is applied to a susceptor 16 serving as a lower electrode. Other configurations are basically the same as those of the plasma etching apparatus shown in FIG. 1. Thus, same reference numerals will be assigned to parts corresponding to those of FIG. 1, and redundant description will be omitted.

[0095]In the second embodiment, the first high frequency power supply 48 for generating plasma and a second high frequency power supply 90 for applying a bias for ion attraction are both connected with the susceptor 16 serving as the lower electrode. The first high frequency power supply 48 is connected with the susceptor 16 via a first matching unit 89. The first matching unit 89 has the same configuration as that of a second matching unit 88, and the first matching unit 89 func...

second embodiment

[0099]The second embodiment is implemented by a plasma etching apparatus of a lower-electrode dual-frequency application type that applies a first high frequency (RF) power for plasma generation and a second high frequency (RF) power for ion attraction to the susceptor 16 serving as the lower electrode. Advantages of this type plasma etching apparatus over the other types of capacitively coupled plasma etching apparatuses are briefly mentioned as follows.

[0100]First, the plasma can be generated closer to the wafer W and the plasma is not diffused widely by applying the high frequency power for plasma generation to the susceptor 16 serving as the lower electrode, and, thus, dissociation of the processing gas can be suppressed. Accordingly, even under condition that the internal pressure of the processing chamber 10 is high and the plasma density is low, it is possible to increase an etching rate of the semiconductor wafer W. Further, even in case that the high frequency power for pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com