Structure and method for self-aligning rotor blade joints

a technology of rotor blades and joints, which is applied in the direction of machines/engines, transportation and packaging, and final product manufacturing, etc., can solve the problems of long road transportation, limited routing of trucks, and high cost of single-piece rotor blades, and achieve the effect of facilitating mating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

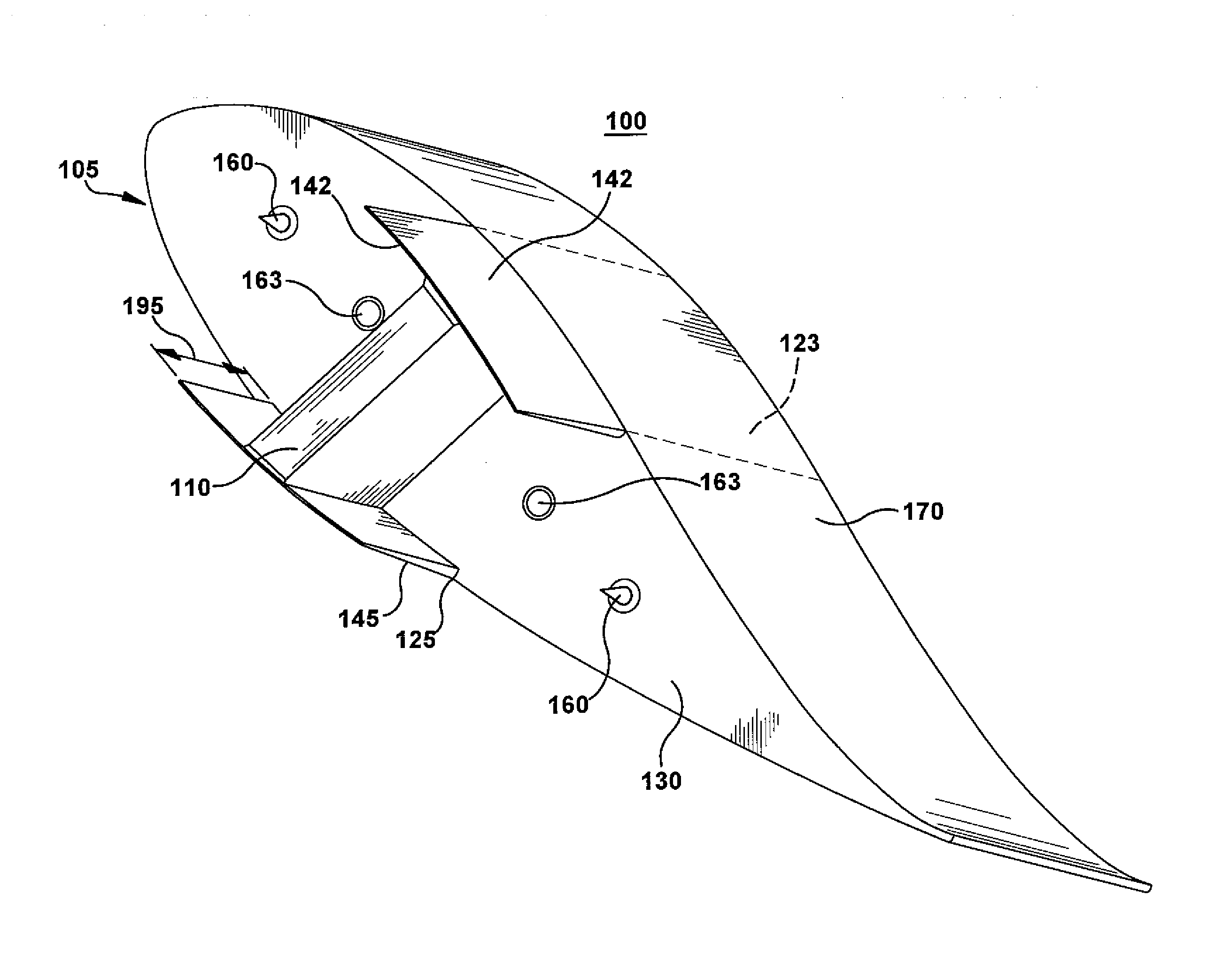

[0028]The following embodiments of the present invention have many advantages, including providing a structure and method for precision alignment of joints between adjacent sections of a wind turbine blade.

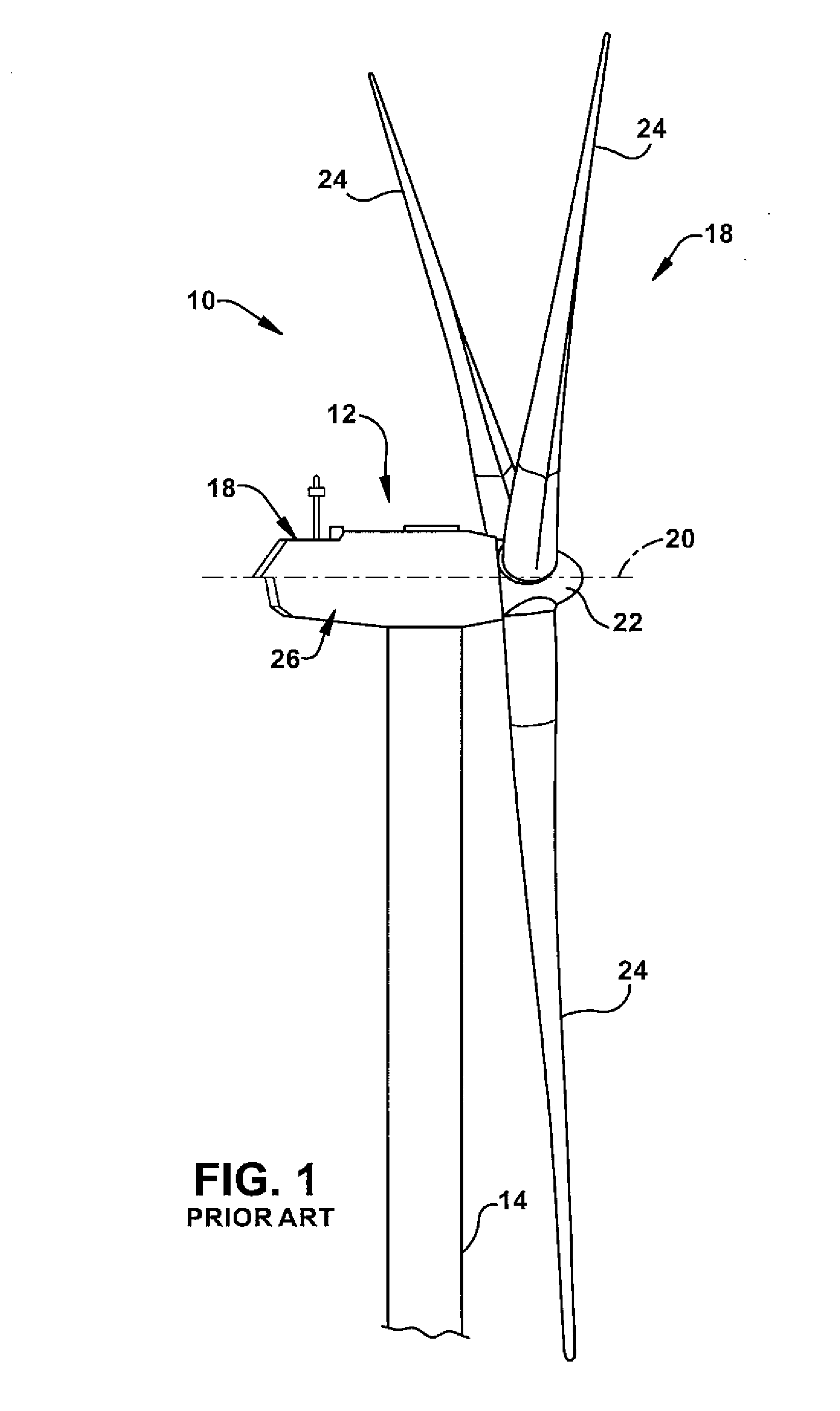

[0029]FIG. 1 is a schematic illustration of an exemplary wind turbine 10. In the exemplary embodiment, wind turbine 10 is a horizontal axis wind turbine. Wind turbine 10 includes a tower 14, a nacelle 16 coupled to tower 14, and a rotor 18 coupled to nacelle 16 for rotation about an axis of rotation 20. Rotor 18 includes a rotatable hub 22 and a plurality of rotor blades (“blades”) 24 coupled to hub 22. In the exemplary embodiment, rotor 18 includes three blades 24. In an alternative embodiment, rotor 18 may include more or less than three blades 24. General operation, dimensions, and configuration of wind turbine 10, and more specifically wind generator 12, is known in the art and therefore will not be described in more detail herein.

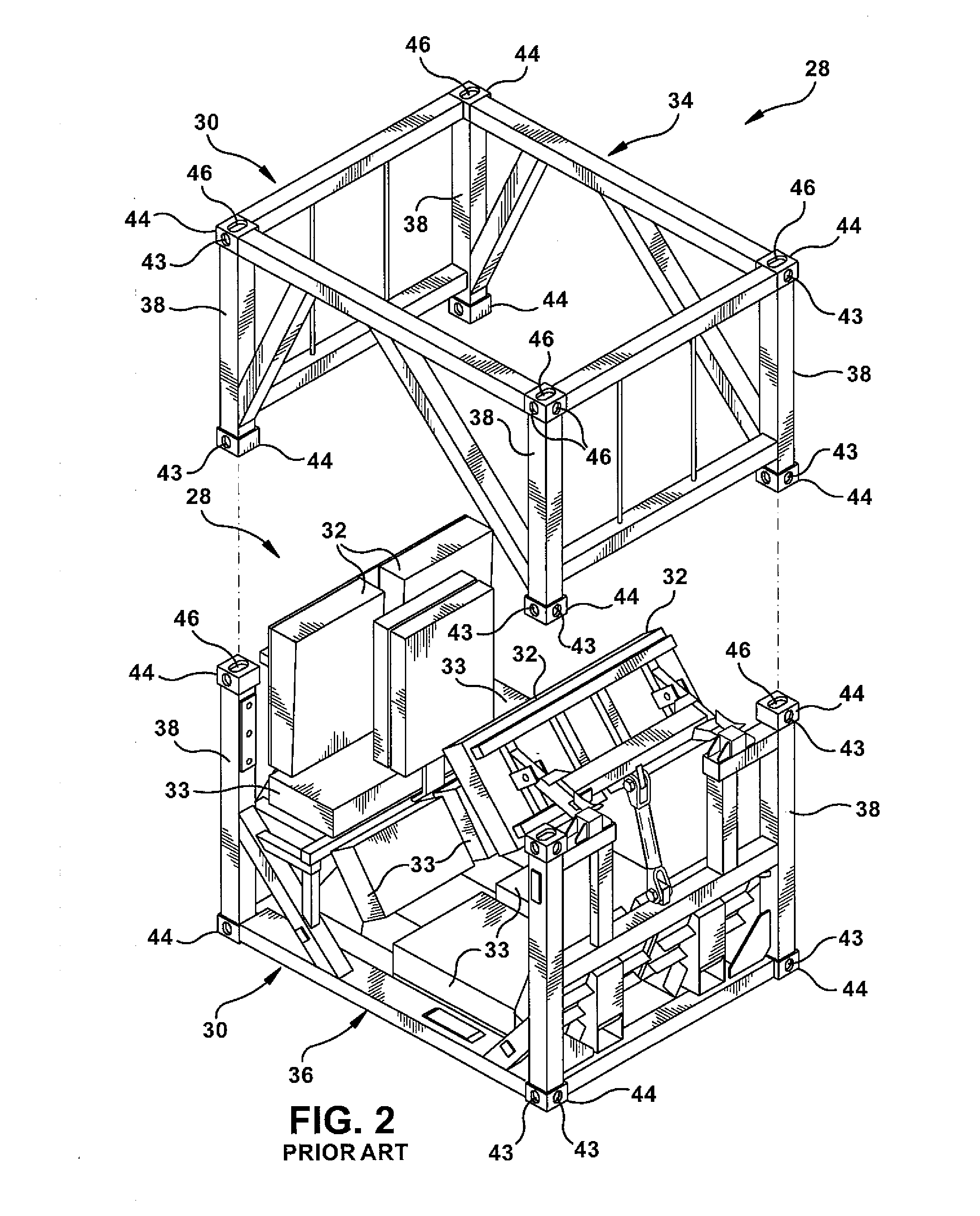

[0030]Normally the body sections of the multi-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lengths | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| physical separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com