Prefabricated staircase and finishing arrangement and installation method therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

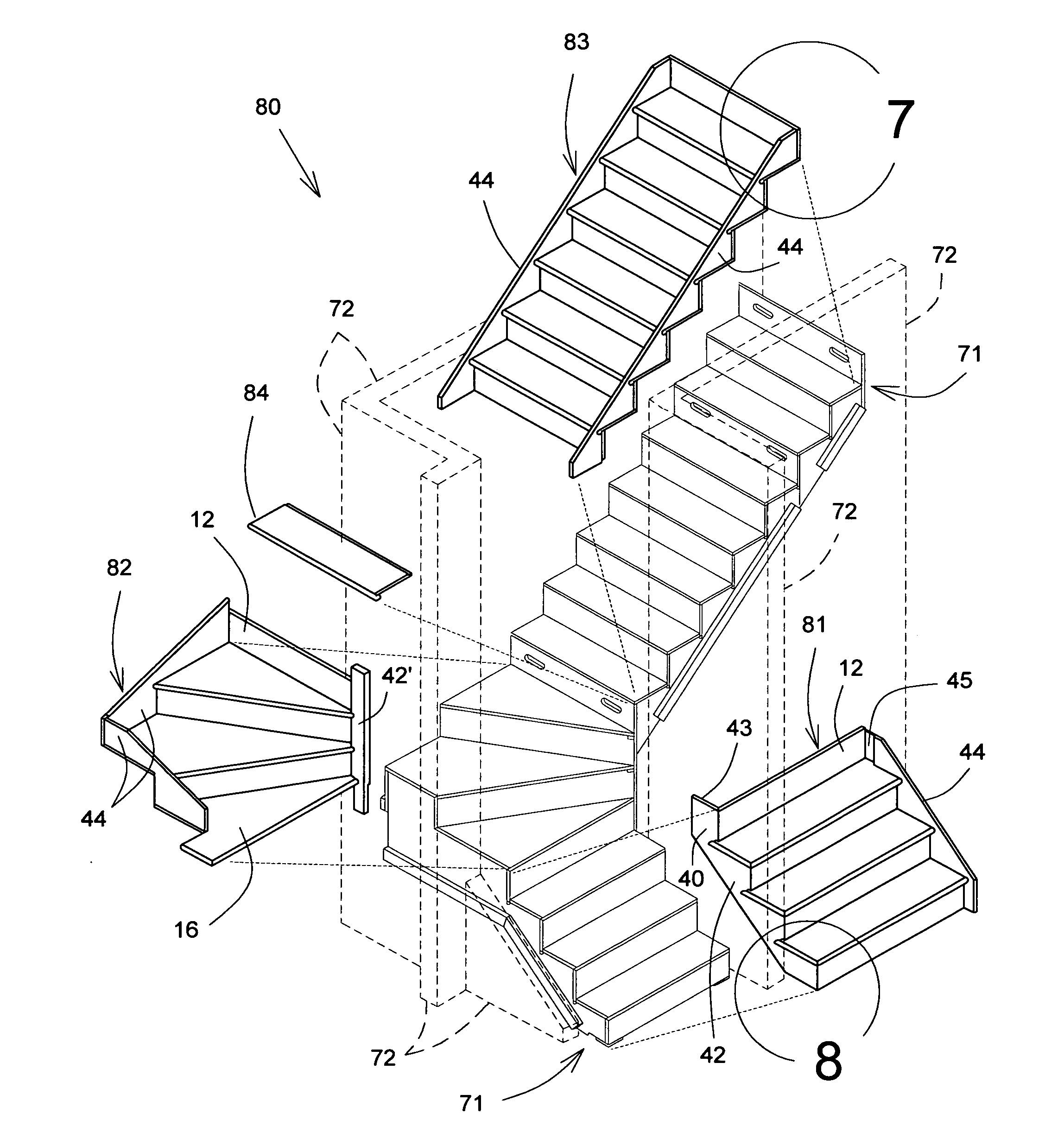

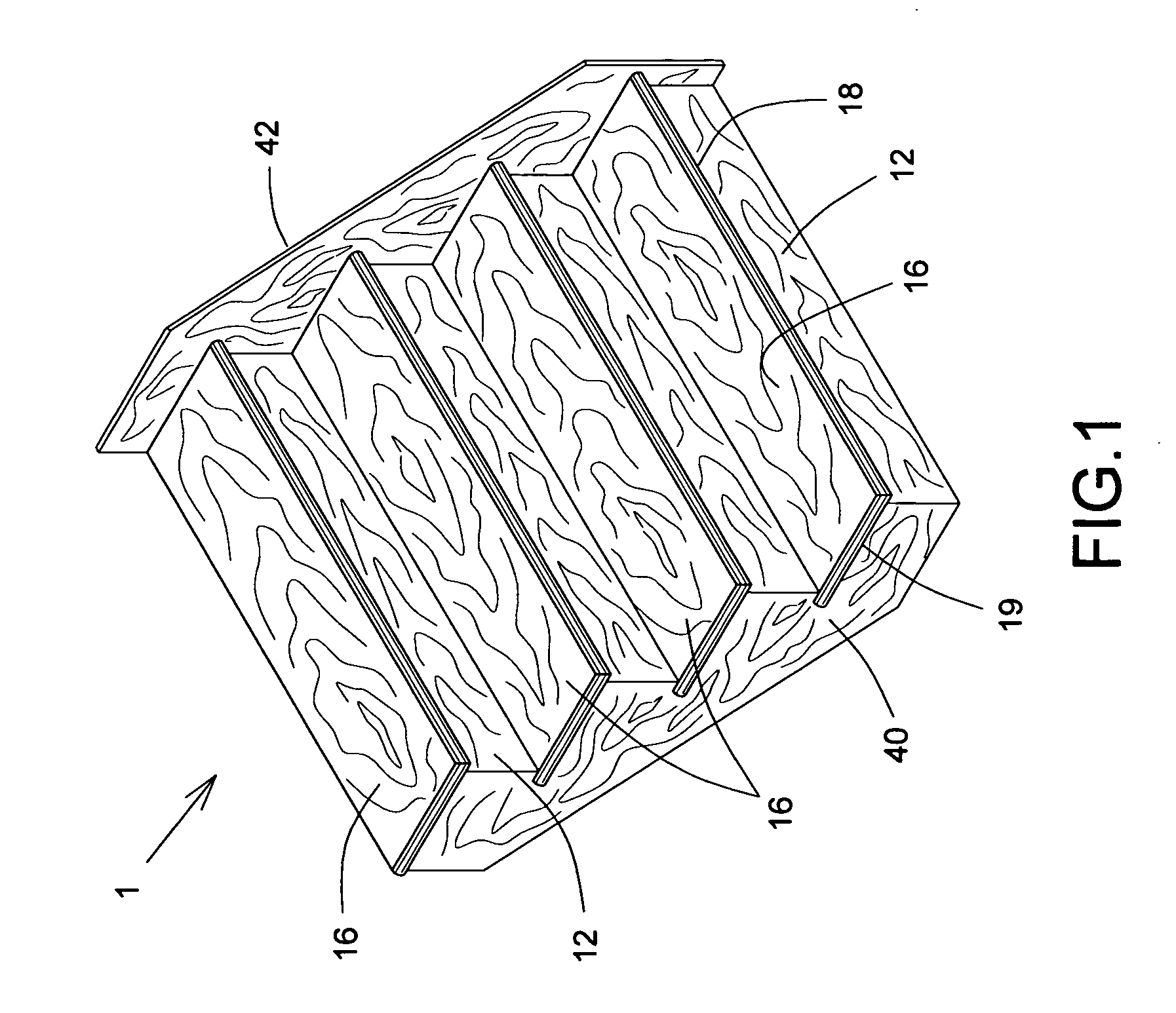

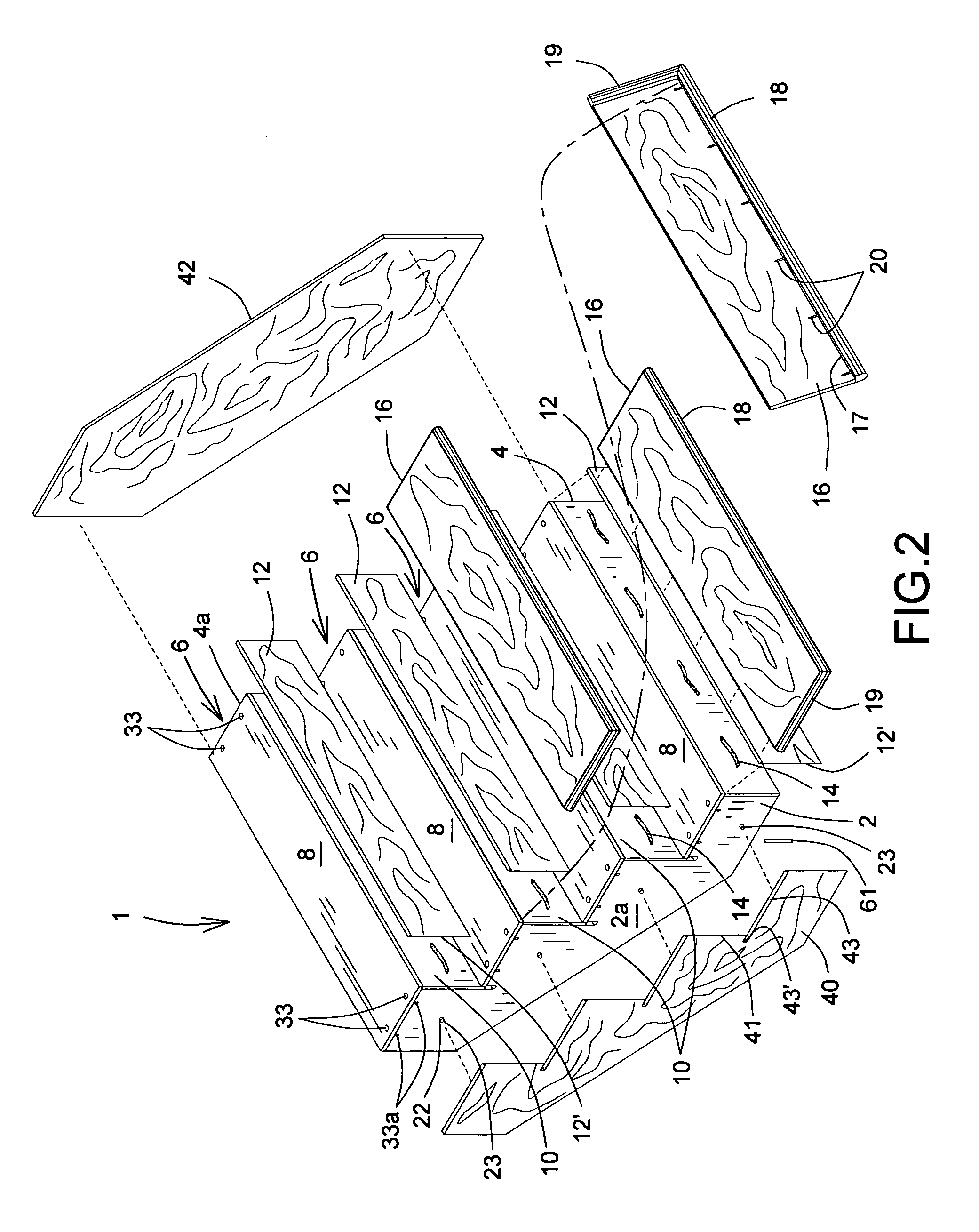

[0048]With reference to the annexed drawings the preferred embodiments of the present invention will be herein described for indicative purpose and by no means as of limitation.

[0049]Referring first to FIG. 2, there is shown a prefabricated staircase 1 in skeletal form, and generally accurate in dimensions, comprising two spaced-apart stringer boards 2, 4 formed to provide the bases for four steps 6. Each step 6 comprises in known manner a tread 8 with a riser 10 in orthogonal horizontal and vertical disposition in relation to one another respectively, each tread having a leading edge covering the top edge of its subjacent riser.

[0050]Decorative pre-finished riser plates 12, with mitred ends 12′, are provided for the risers 10 of each step 6 and are bonded thereto by a suitable adhesive diagrammatically indicated by glue beads 14. Decorative pre-finished tread plates 16 are provided for the treads 8. Each tread plate 16 has a decorative nosing 18 forming a front edge thereof and a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com