Methods and systems for cleaning heat exchange surfaces of a heat exchange system

a heat exchange system and surface cleaning technology, applied in the field of process industry, can solve the problems of eroding the walls of heat exchanger tubes, affecting the efficiency of heat exchangers, and not providing the minimum emission level of fuel flow, so as to achieve the effect of cleaning the heat exchange system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

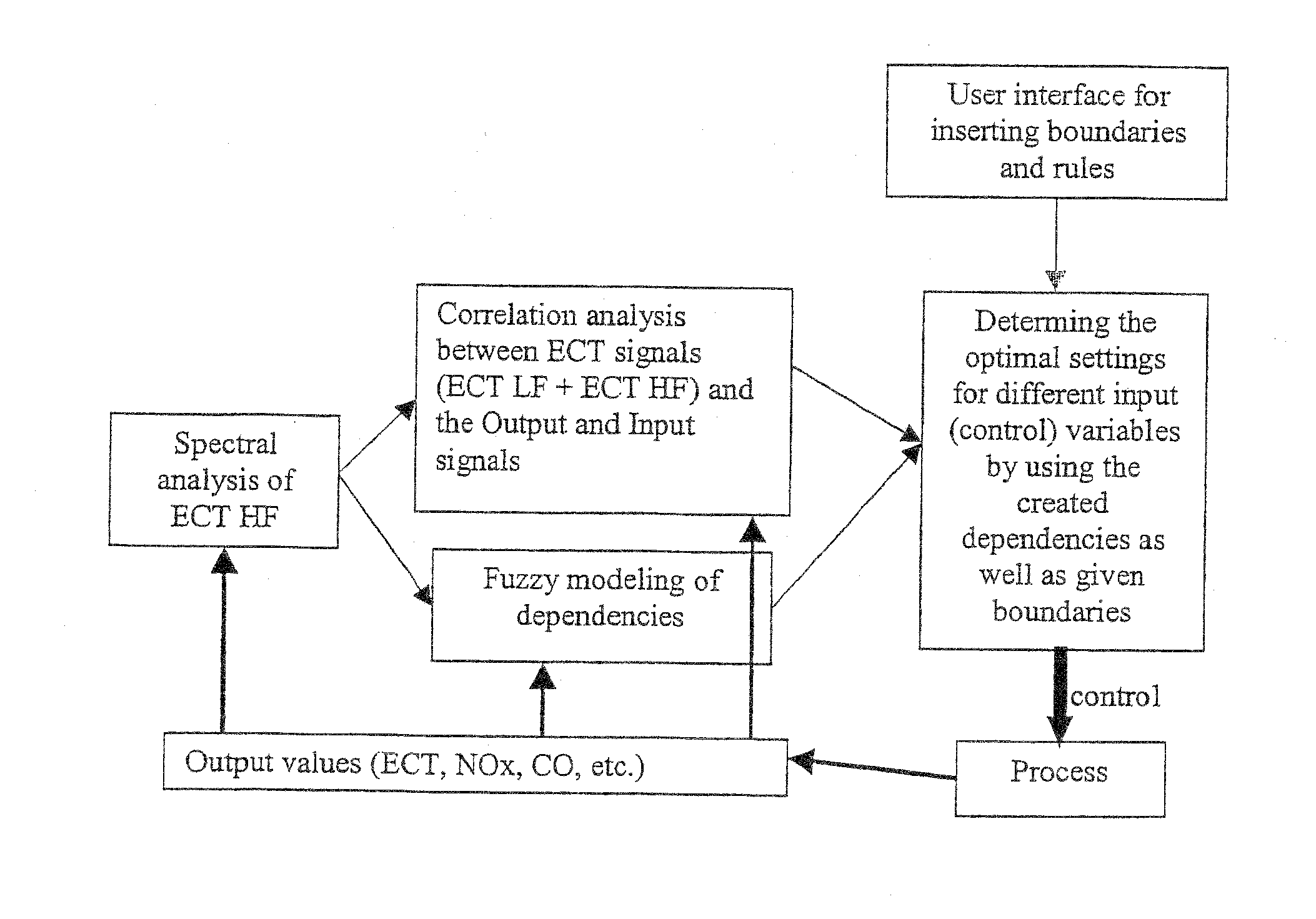

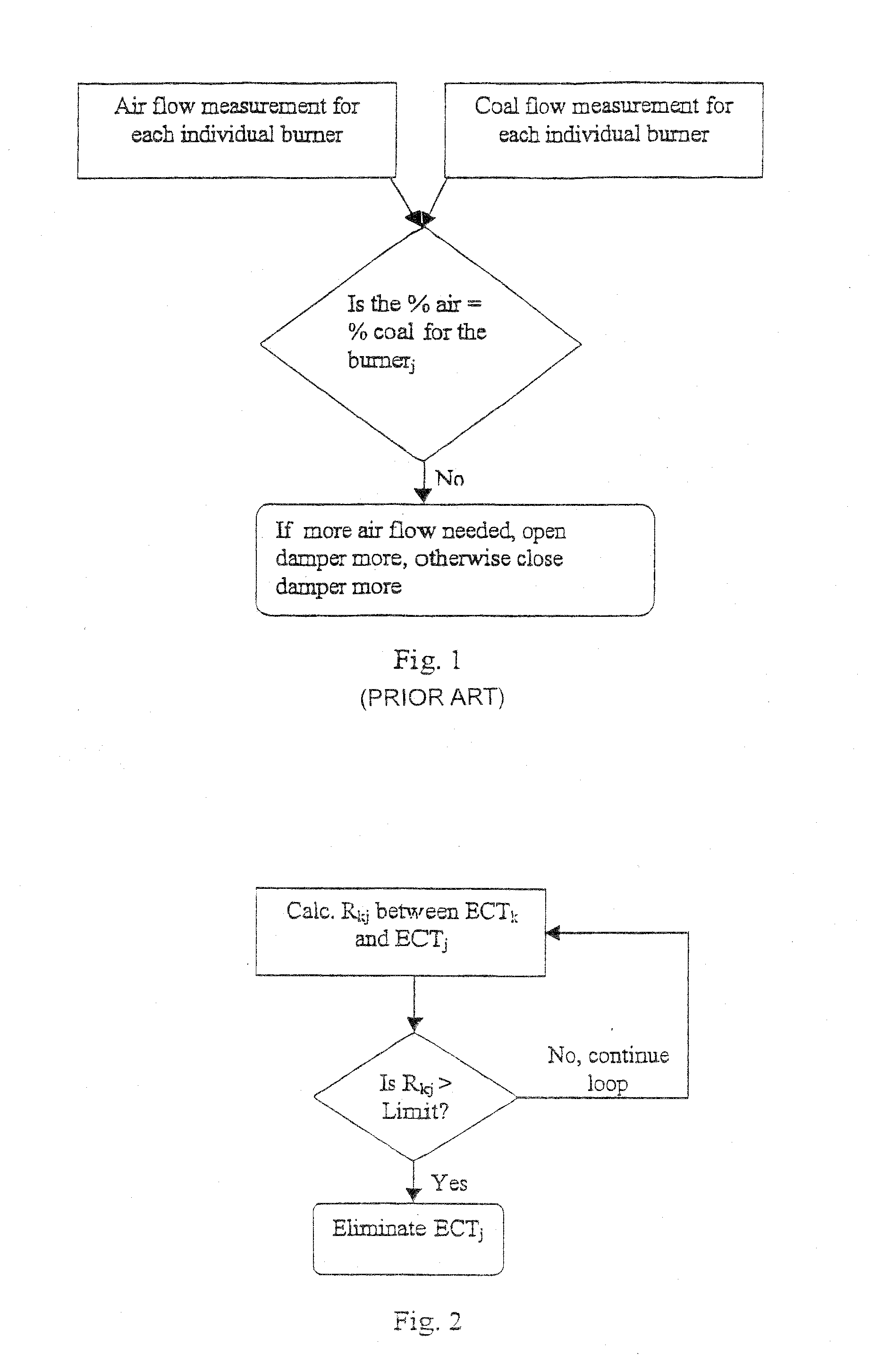

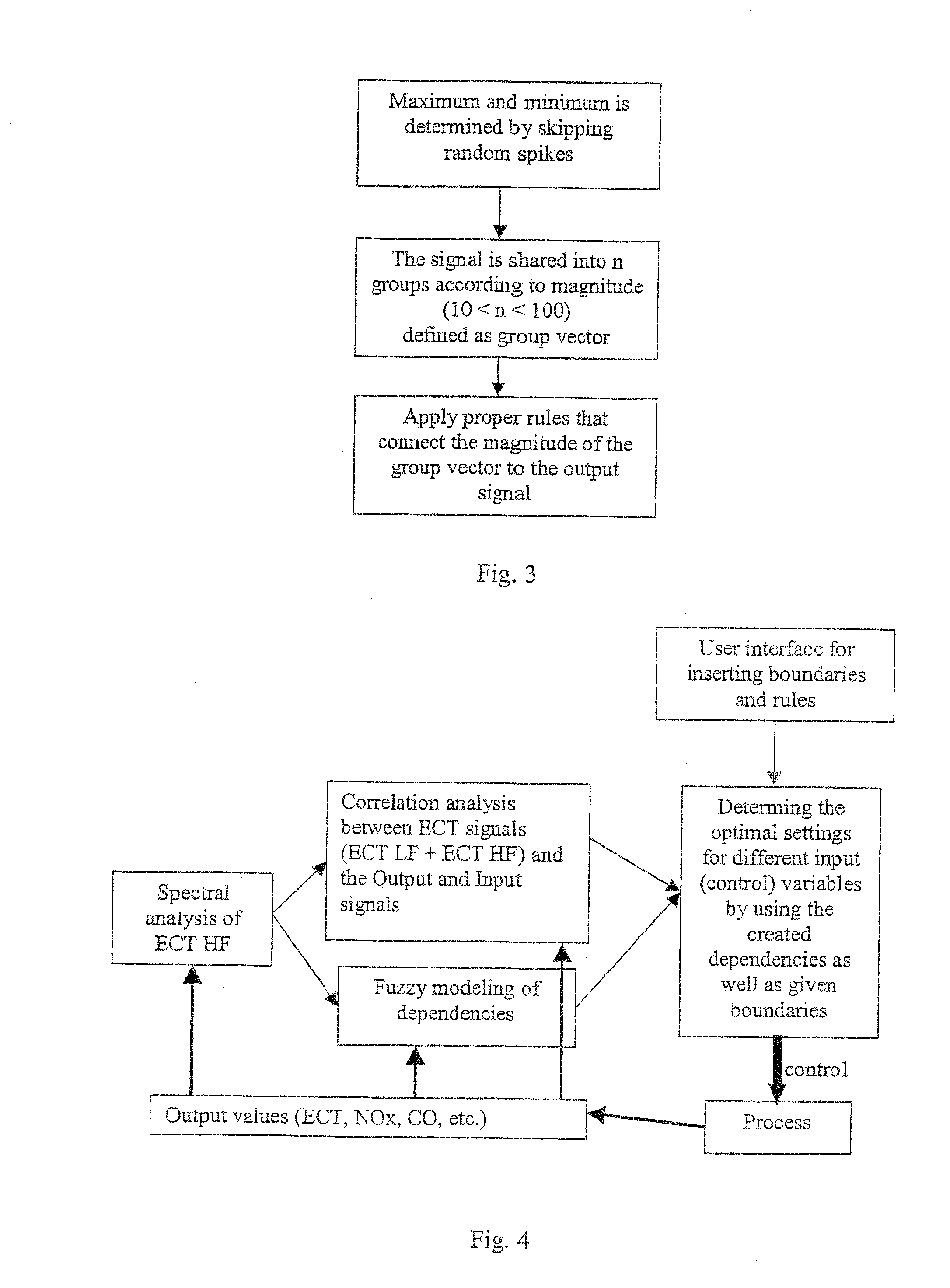

[0069]Generally, the first aspect of the invention provides a method for air / fuel control in burners, such as pulverized coal boiler, based on a measurement of a flow of particles for a suspension of gas and solids. The measurement can be used e.g. by using the measurement system disclosed in the applicant's earlier patent publication U.S. Pat. No. 6,031,378 and / or the method disclosed in the applicant's earlier patent publication WO 02 / 06775. The measurement system (Electric Charge Transfer System, ECT-system), disclosed in the above-mentioned patent publications, is able to measure e.g. the velocity and the mass flow of particles for a suspension of gas and solids. The ECT measurement is of a local character, that is, the signal caused by the flowing particles is a function of distance from the particles to the ECT antenna. Therefore, a big duct normally requires use of many ECT antennas. It should be noticed that the particles entrained in the gas flow are not necessarily evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com