Forming Multiple Deviated Wellbores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

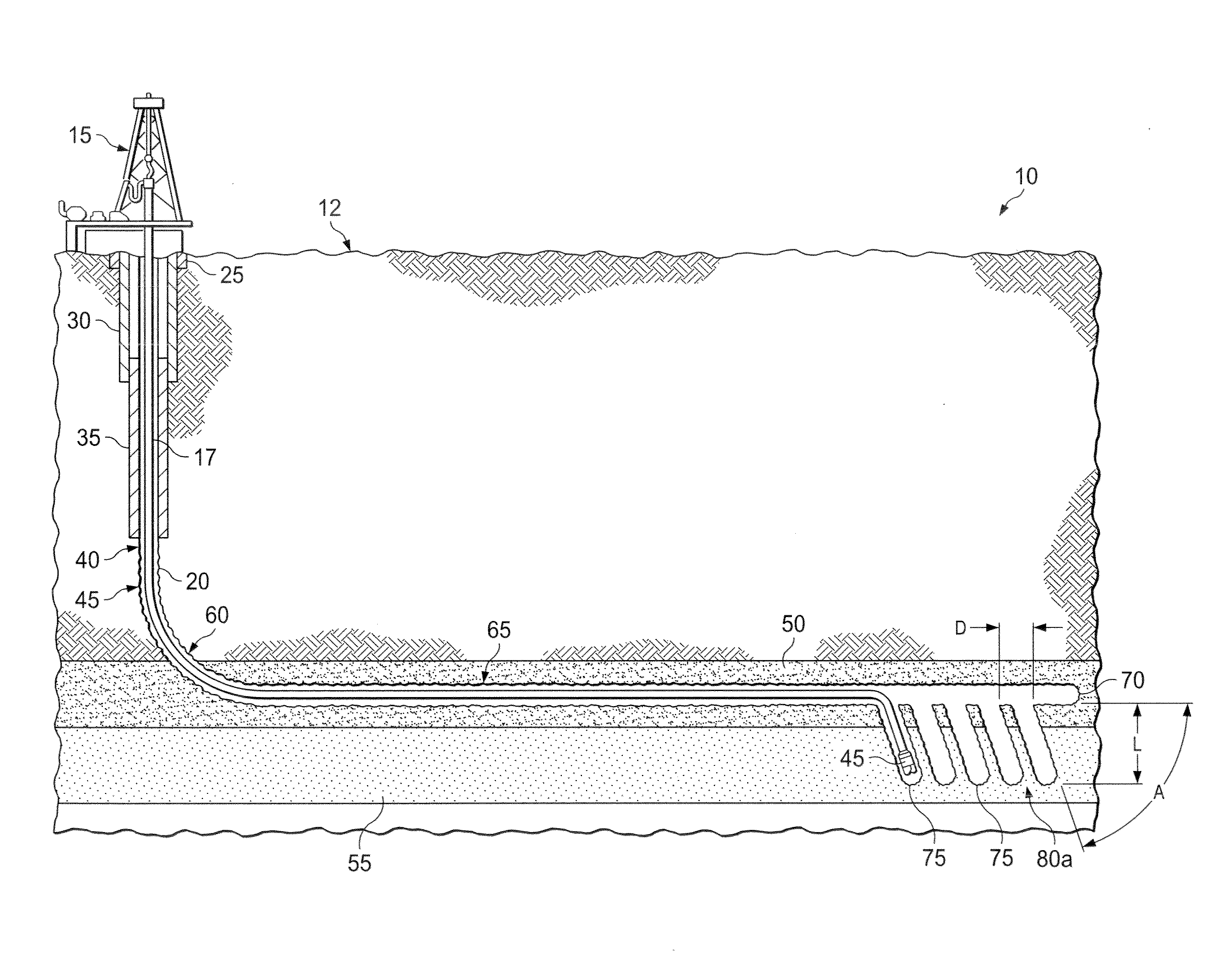

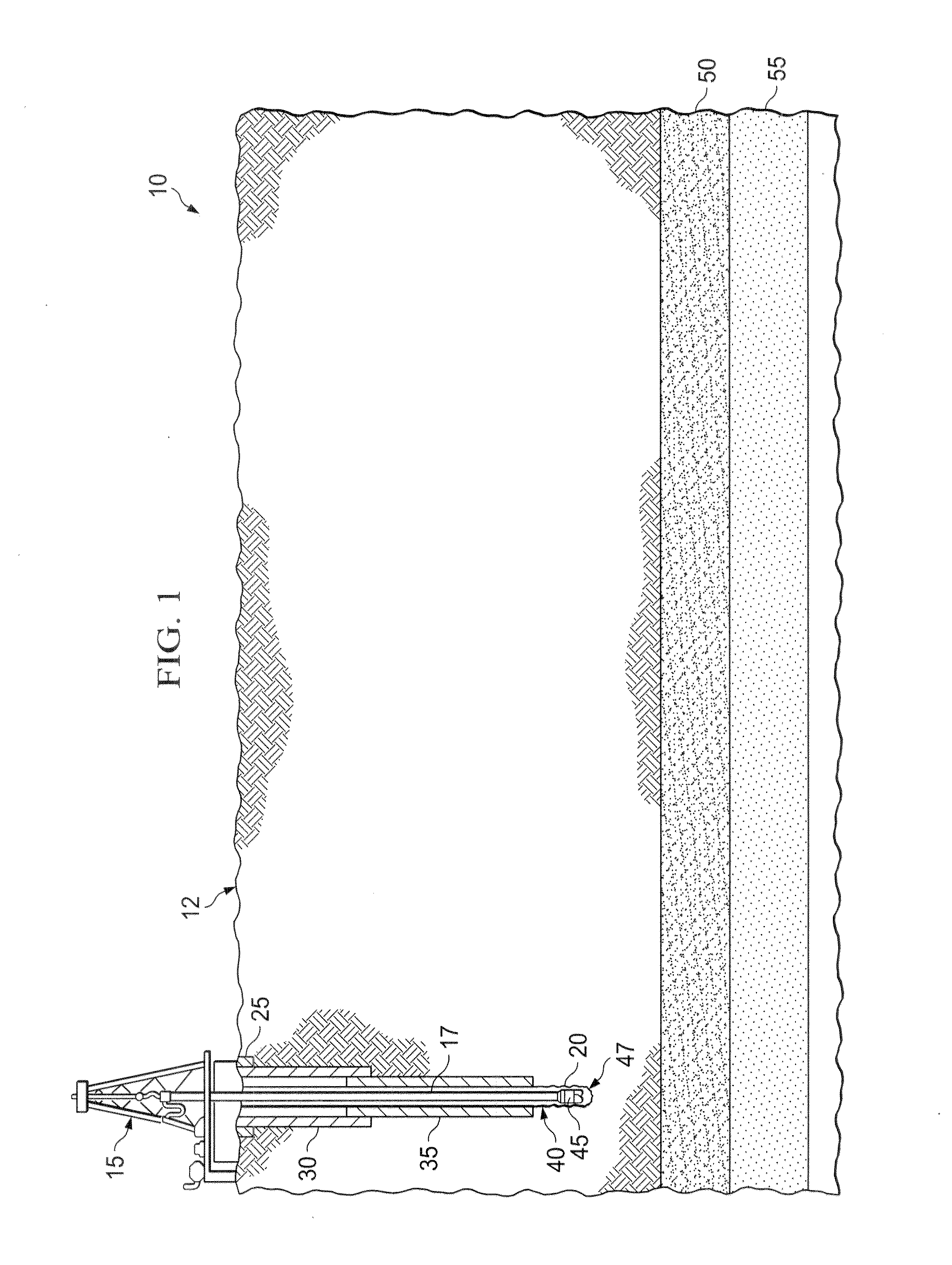

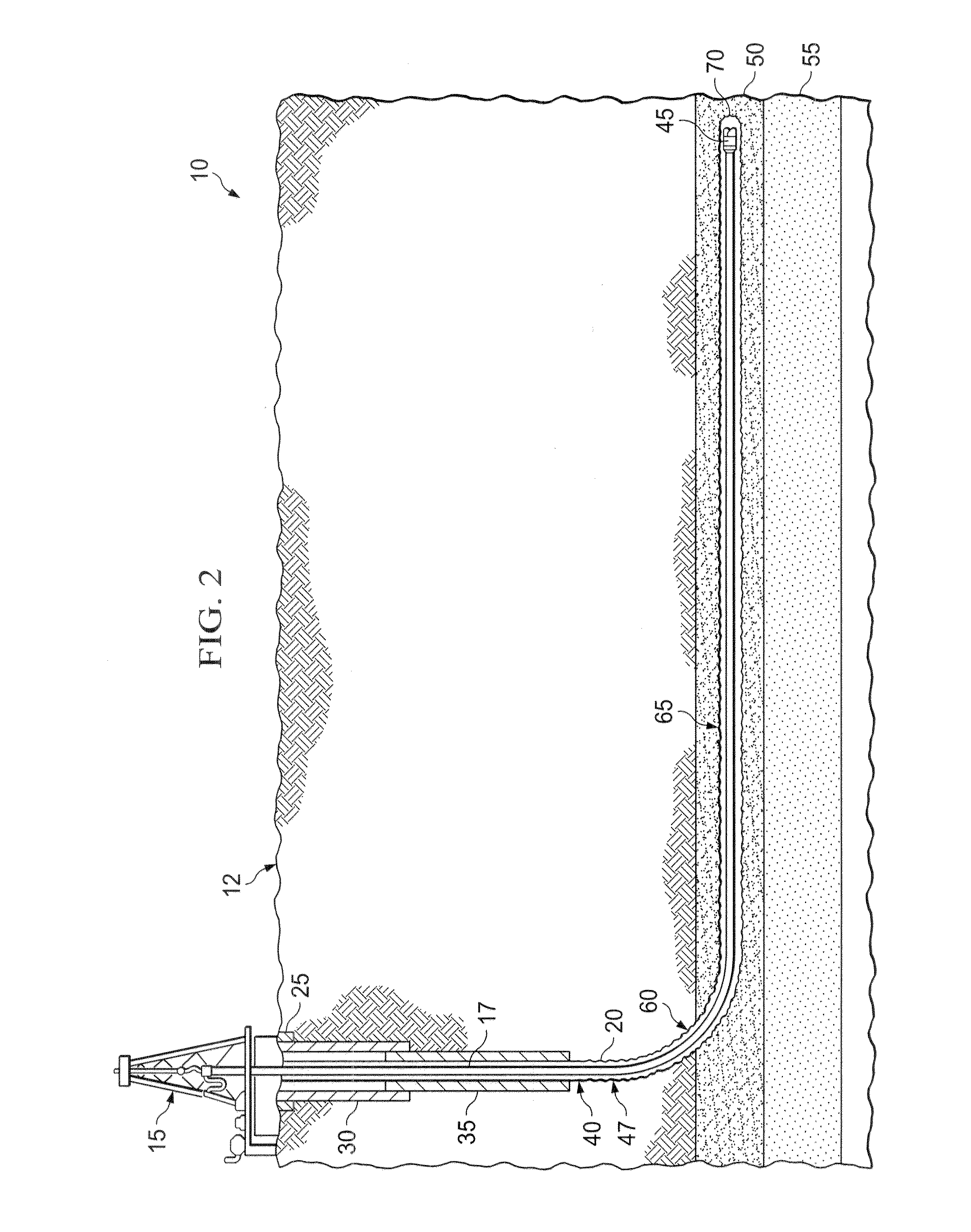

[0030]In some embodiments, a deviated wellbore system according to the present disclosure includes an articulated wellbore drilled from the surface to a target geological formation located above the target productive formation. The articulated wellbore may include a substantially vertical portion, a radiused portion, and a substantially horizontal portion landing in the target geological formation to be drilled horizontally. In some embodiments, the target geological formation is located adjacent a production formation containing one or more hydrocarbons, such as oil or gas. In some embodiments, the production formation may be a formation containing natural gas such as a shale formation, siltstone, sandstone matrix or limestone matrix. The deviated wellbore system may also include one or more deviated wellbores, or completion paths (e.g., production, fracture, stimulation paths), drilled from the substantially horizontal portion of the wellbore into the productive formation. Complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com