Thermal energy storage vessel, systems, and methods

a technology of thermal energy storage and energy storage tanks, applied in the field of energy storage, can solve the problems of requiring a disruptive thawing process step to restart the system, the solution does not produce any power, and the problem of requiring a disruptive thawing process step to achieve the effect of a single tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

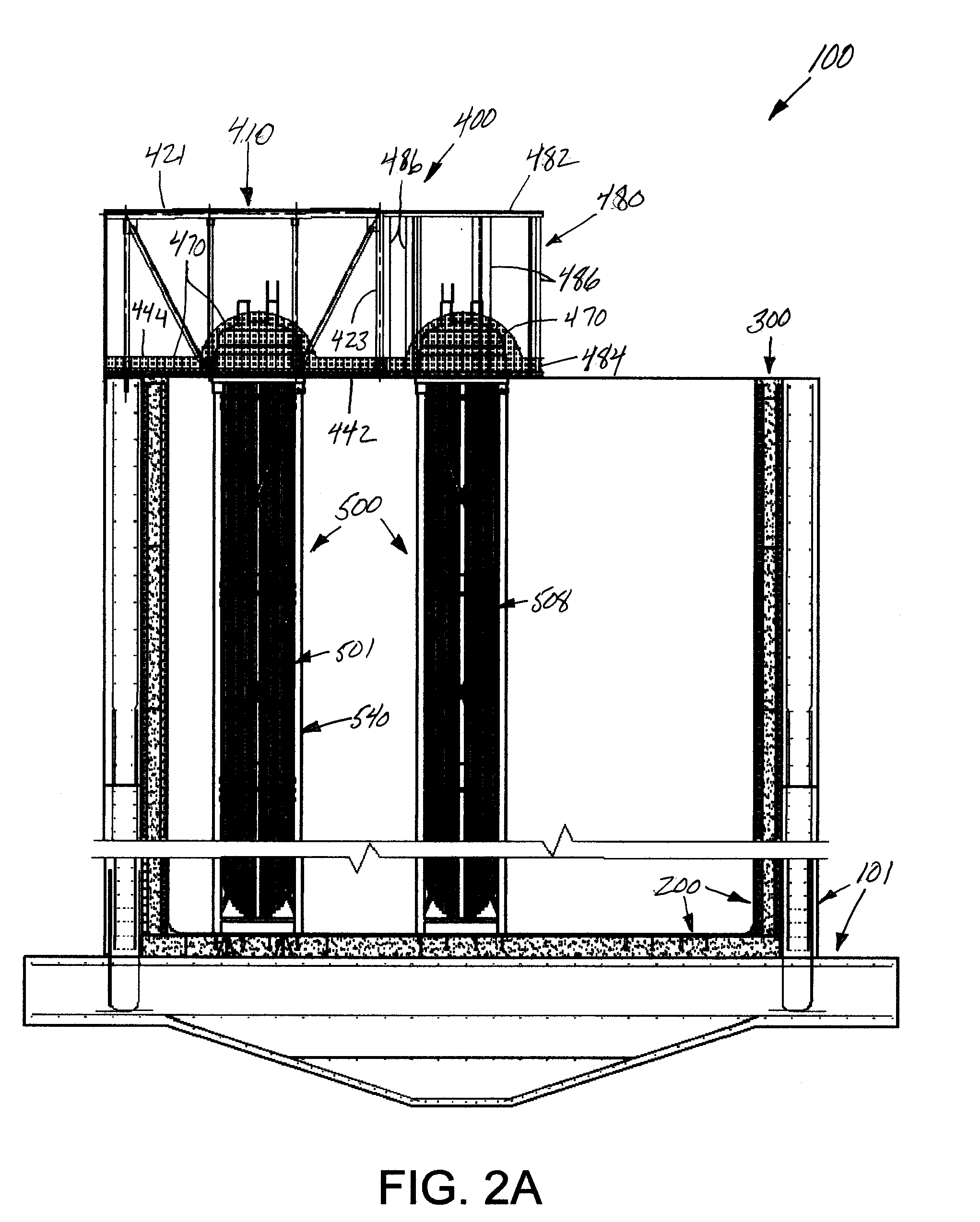

[0061]For a general understanding of the present invention, reference is made to the drawings. In the drawings, like reference numerals have been used throughout to designate identical elements.

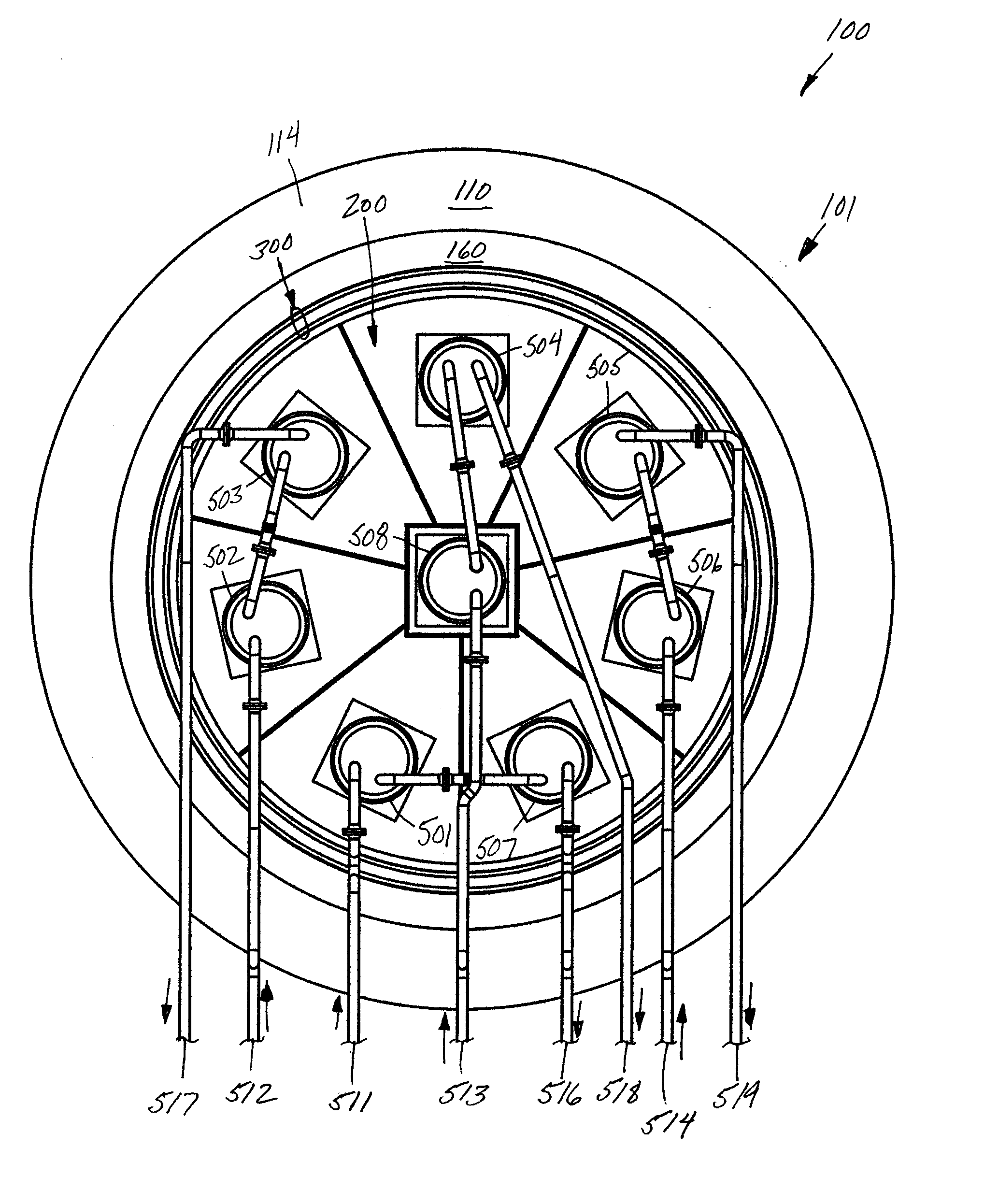

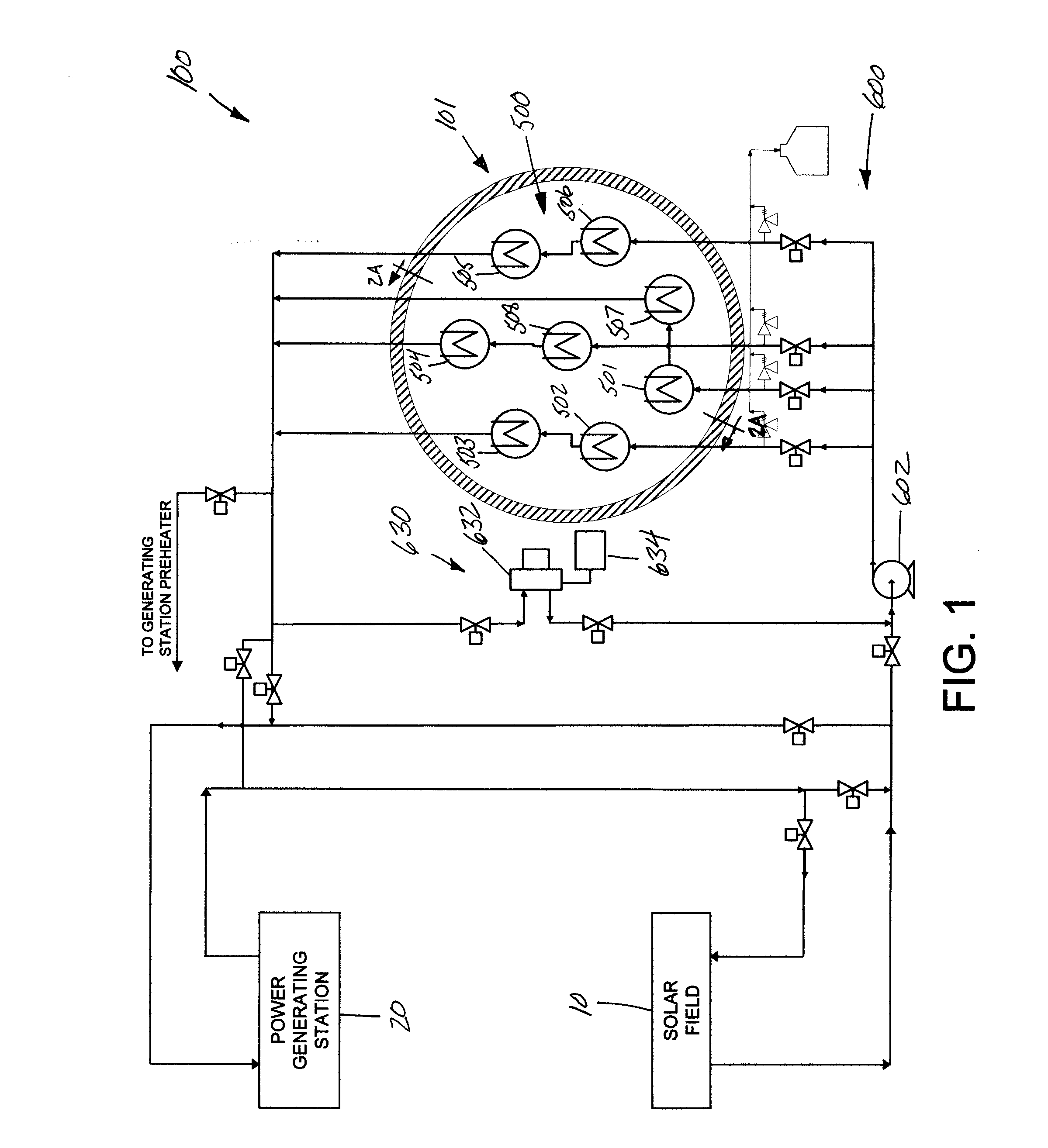

[0062]FIG. 1 is a schematic illustration of a thermal storage system and method in accordance with the present disclosure. The thermal energy storage system 100 is comprised of a containment vessel 101, which contains a heat exchanger or an array 500 of heat exchangers immersed in a molten salt. The system 100 is further comprised of a liquid transfer unit 600 (that may be of a modular design), which circulates a heat transfer fluid through the heat exchangers during operation of the system 100. The liquid transfer unit 600 is comprised of liquid piping, various switching and control valves, a pump 602, and a pressure relief tank 604. The liquid transfer unit 600 may further include a heater loop 630 comprising an oil heater 632 and an expansion tank 634 for heating and circulating heat trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com