Processes for removing hydrogen sulfide from refined hydrocarbon streams

a technology of hydrocarbon stream and hydrogen sulfide, which is applied in the direction of hydrocarbon oil treatment, thermal non-catalytic cracking, fuels, etc., can solve the problems of increased corrosion rate of hydrocarbon processing, high corrosive and poisonous in very small concentrations, and troughing of processing or refinery equipment, so as to reduce the amount of hydrogen sulfide and reduce the amount of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0043]Glyoxal is an aqueous-based compound having a pH from about 2 to about 3. When dispersed in refined hydrocarbon streams, it will eventually settle out of the refined hydrocarbon streams into an acidic aqueous phase and settle to the bottom of processing equipment causing corrosion. To test the efficiacy of the corrosion inhibitor for reducing corrosion, the corrosion test was simulated in water.

[0044]Two metal coupons of Carbon C010 steel were weighed and added to two spindles mounted on a stirring shaft in an 800 ml Auto-Clave. The metal coupons were 180° from each other. The stirring shaft was placed into water and stirred at the revolutions per minute as shown in Table 1. The revolutions per minute were used to calculate the approximate flow through a pipeline and are shown in Table 1. A corrosion inhibitor was added to the water at room temperature in the amounts shown in Table 1. 15 minutes later, glyoxal was injected into the water in the amounts shown in Table 1. The Au...

example 2

[0046]Additional corrosion tests were performed on organic soluble corrosion inhibitors and were conducted in water in accordance with Example 1. Results are shown in Table 2.

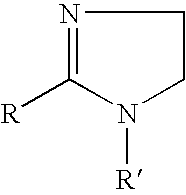

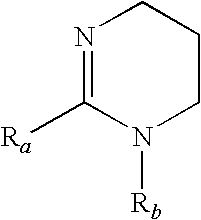

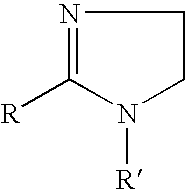

TABLE 2CorrosionGlyoxal1InhibitorCorrosion(ppm by(ppm byRateSamplevolume)Corrosion Inhibitorvolume)(MPY)CE-3500NoneNone91.71500Oleic acid Pyrmidine and10039.2Dimer / Trimer Acid (3:1 wtratio)2CE-4500Dimer / Trimer acid32551.82500Oleic acid Imidazoline42517.33500Oleic acid Imidazoline and2423.3Dimer / Trimer Acid (3:1 wt.Ratio)4500Oleic acid Imidazoline and10014.0Hydroxyacetic acid (3:1 wtratio)55500Oleic acid Pyrimidine610010.01Glyoxal used contains 2% by weight quaternary ammonium catalyst and is available commercially as S-1750 from GE Water.2Available commercially as Philmplus ™ 5K 1642 from GE Water.3Available commercially as Sylvadym ® T-18 from Sylvachem Corp.4Available commercially as CI-11C from GE Water.5Available commercially as 5K2S from GE Water.6Available commercially as 5K7 from GE Water.

[0047]The organ...

example 3

[0048]Corrosion experiments and hydrogen sulfide scavenging were tested in a mixture of oil gas and water in an 800 ml Auto-Clave. The gas oil was initially spiked with an approximate 0.5 wt. % solution of H2S in kerosene before being mixed with the water. Two metal coupons of Carbon C1010 steel were weighed and added to two spindles mounted on a stirring shaft. The metal coupons were 180° from each other. The stirring shaft was placed into the gas oil and water mixture and stirred at 300 rpm. The mixture of oil gas and water was 200 ml of gas oil and 400 ml of water. The 2:1 volume ratio of water to gas oil ensured that the coupons were always immersed in water @ 300 rpm to test the corrosion in an aqueous phase. A corrosion inhibitor was added to the gas oil mixture at room temperature in the amounts shown in Table 3. 15 minutes later, glyoxal was injected into the gas oil mixture in the amounts shown in Table 3. The Auto-Clave was sealed and the gas oil and water mixture was heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com