Compositions and methods for coating surfaces

a technology of coating and surface, applied in the direction of building components, building insulation, floors, etc., can solve the problems of stucco cladding being quite porous and easily penetrated, surface cracking in acrylic-based finish coats is not completely eliminated, and the cracking is not completely eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Overview

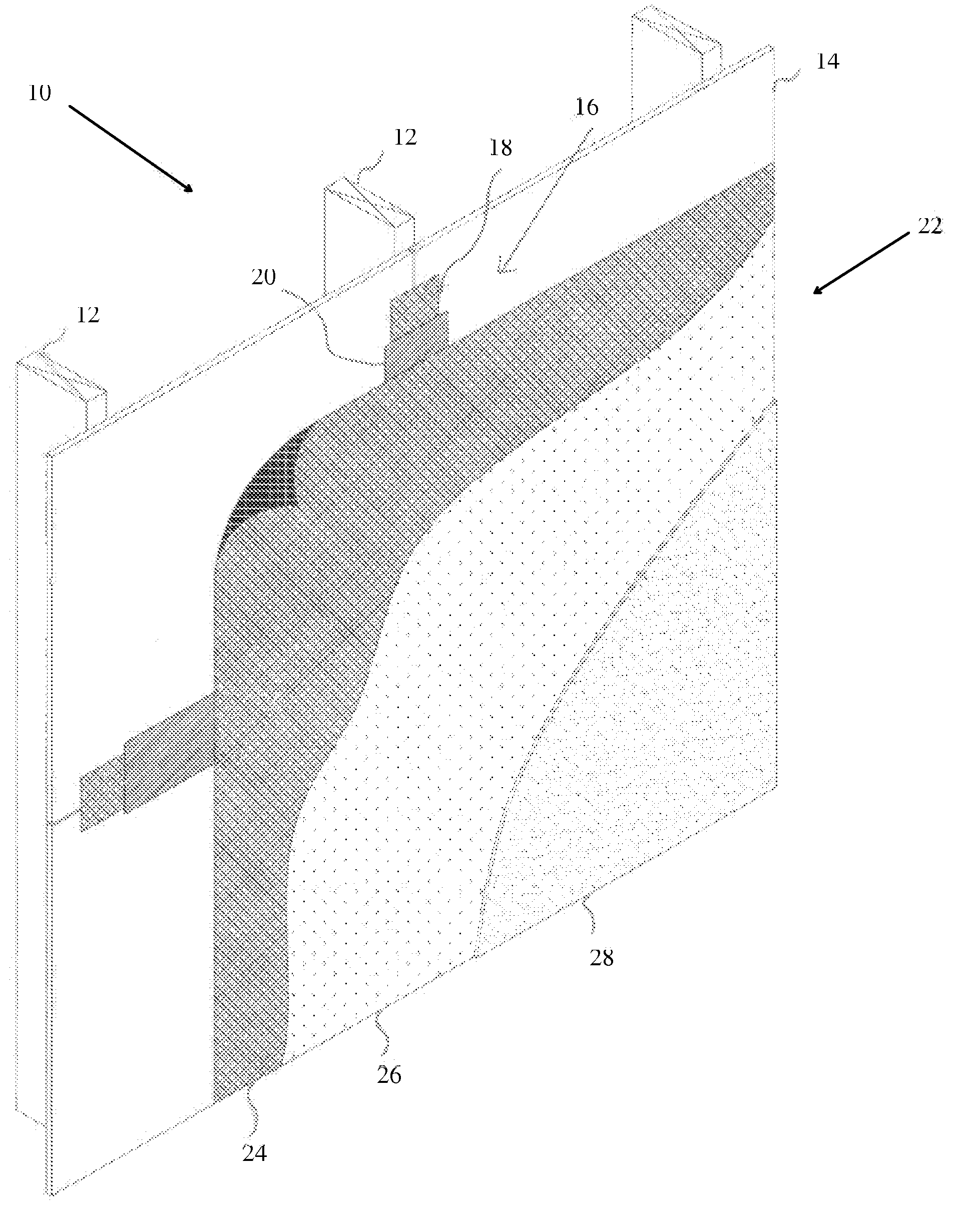

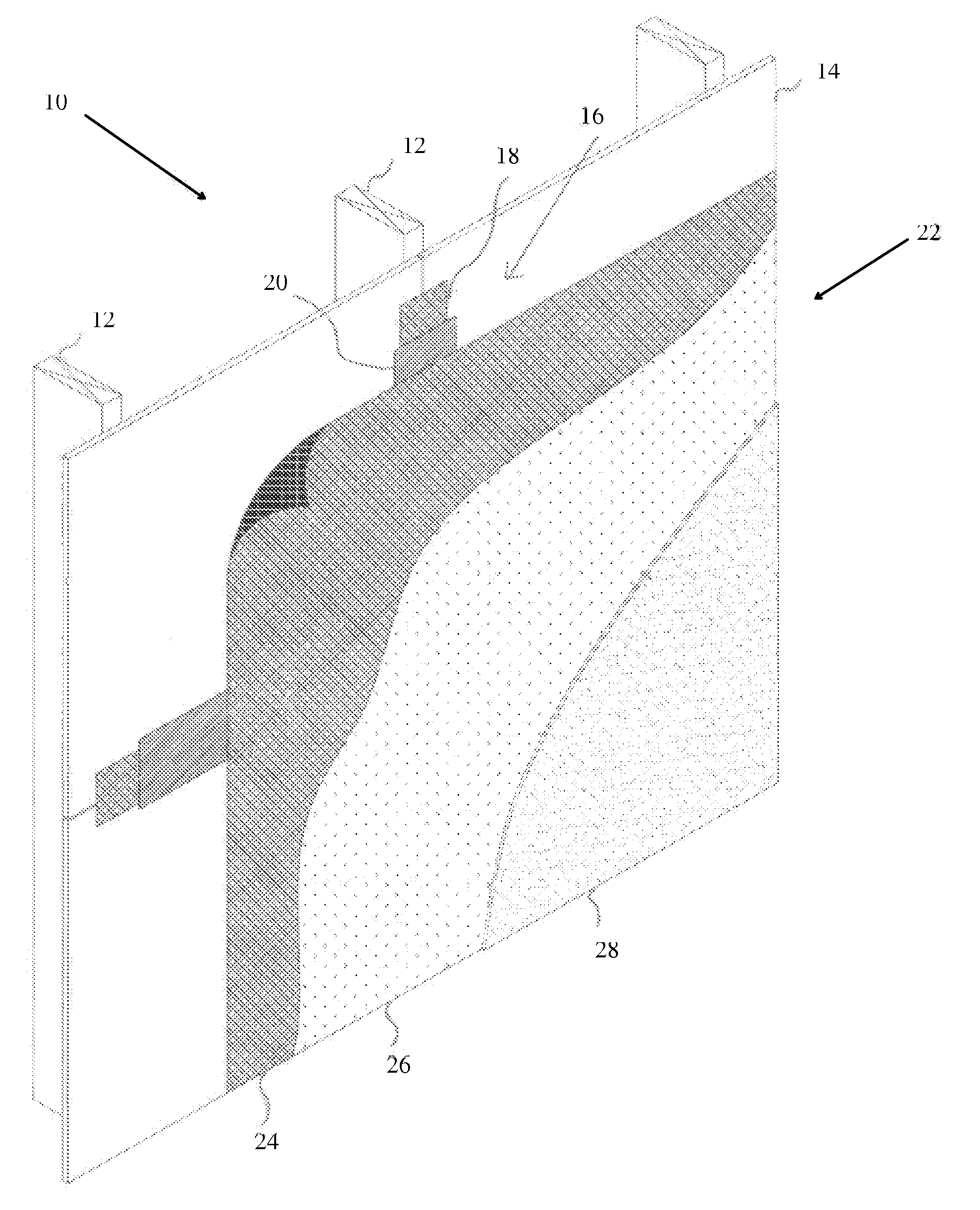

[0035]With reference to the FIGURE, a layered exterior cladding system (ECS) 10 is described.

[0036]As shown in FIG. 1, the ECS 10 is preferably applied directly to a frame constructed wall with a wood-based substrate. As shown, the typical wood frame wall includes evenly spaced structural members 12 and exterior panels or sheathing 14. The ECS can also be applied to non-wood substrates, such as cementitious-based substrates and insulated concrete forms (ICF's) made of expanded polystyrene foam (EPS), with additional surface preparation. Importantly, the subject system does not require the use of metal fasteners and, as explained in greater detail below, creates a watertight surface in which the underlying sheathing is not compromised by penetrating fasteners. In addition, the system eliminates the need for house wrap and wire meshes.

[0037]In accordance with the invention, the ECS includes a joint sealing system 16 that is comprised of a first mesh layer 18, a joint compound ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bond strength | aaaaa | aaaaa |

| bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com