Chemical heat-storage apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

storage process in the heat storage system illustrated in FIG. 1.

[0022]FIG. 10 is an operational diagram illustrating the heat release process in the heat storage system illustrated in FIG. 1.

[0023]FIG. 11 is a phase diagram indicating the transformation of the heat storage material (calcium chloride hydrate).

[0024]FIG. 12 is a schematic diagram illustrating a conventional latent heat storage apparatus.

[0025]FIG. 13 is a schematic diagram illustrating a conventional chemical heat-storage apparatus.

BEST MODE FOR CARRYING OUT THE INVENTION

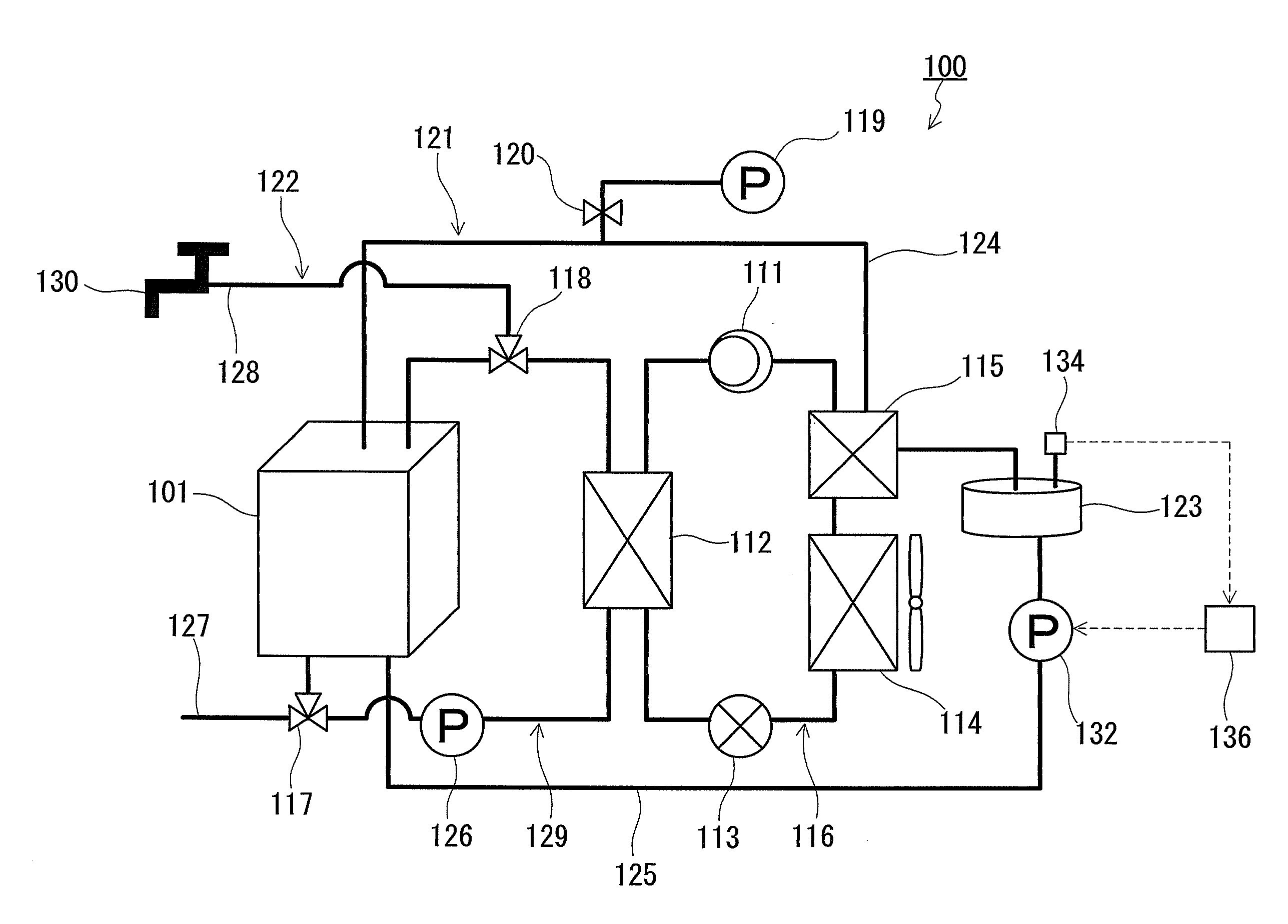

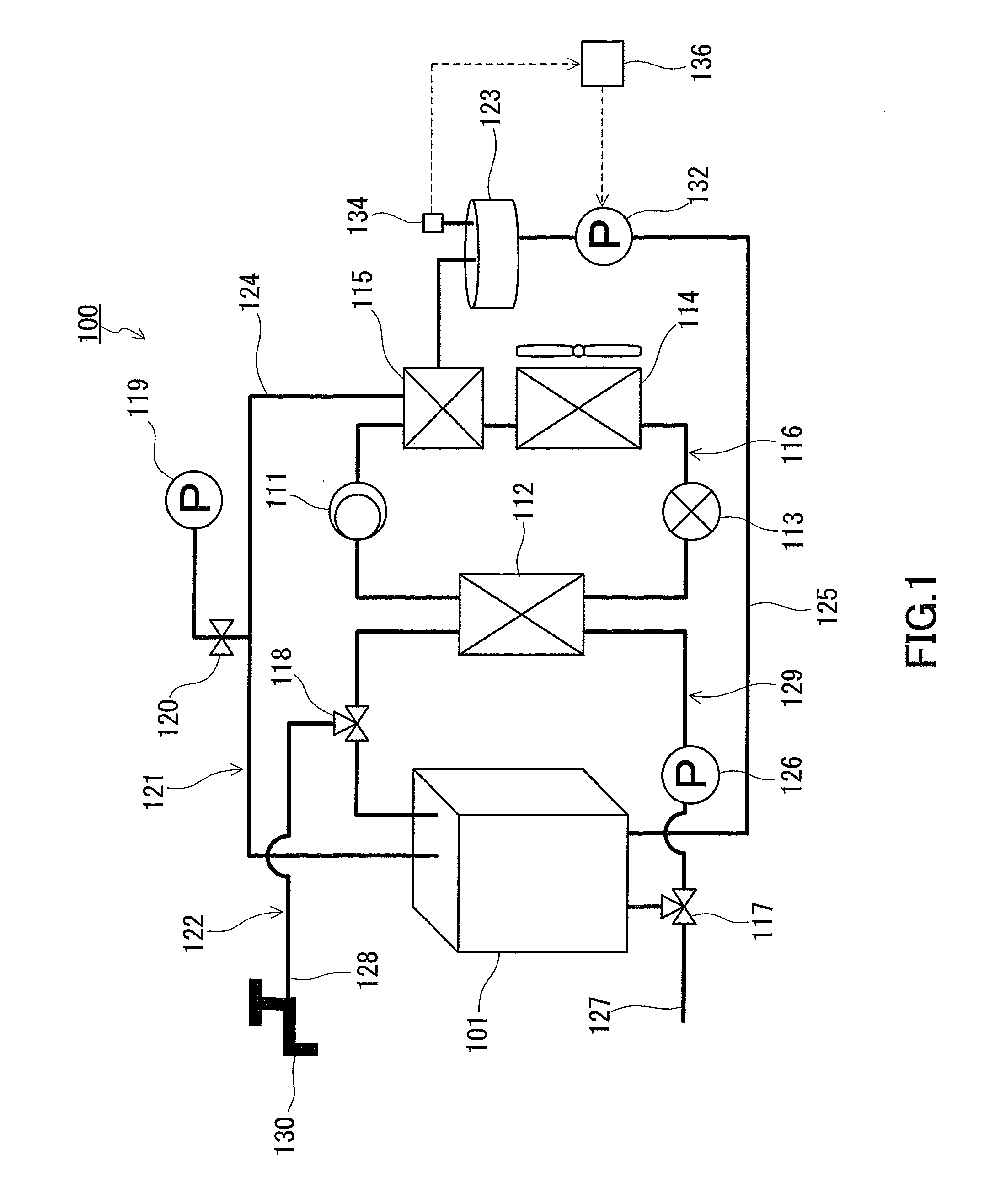

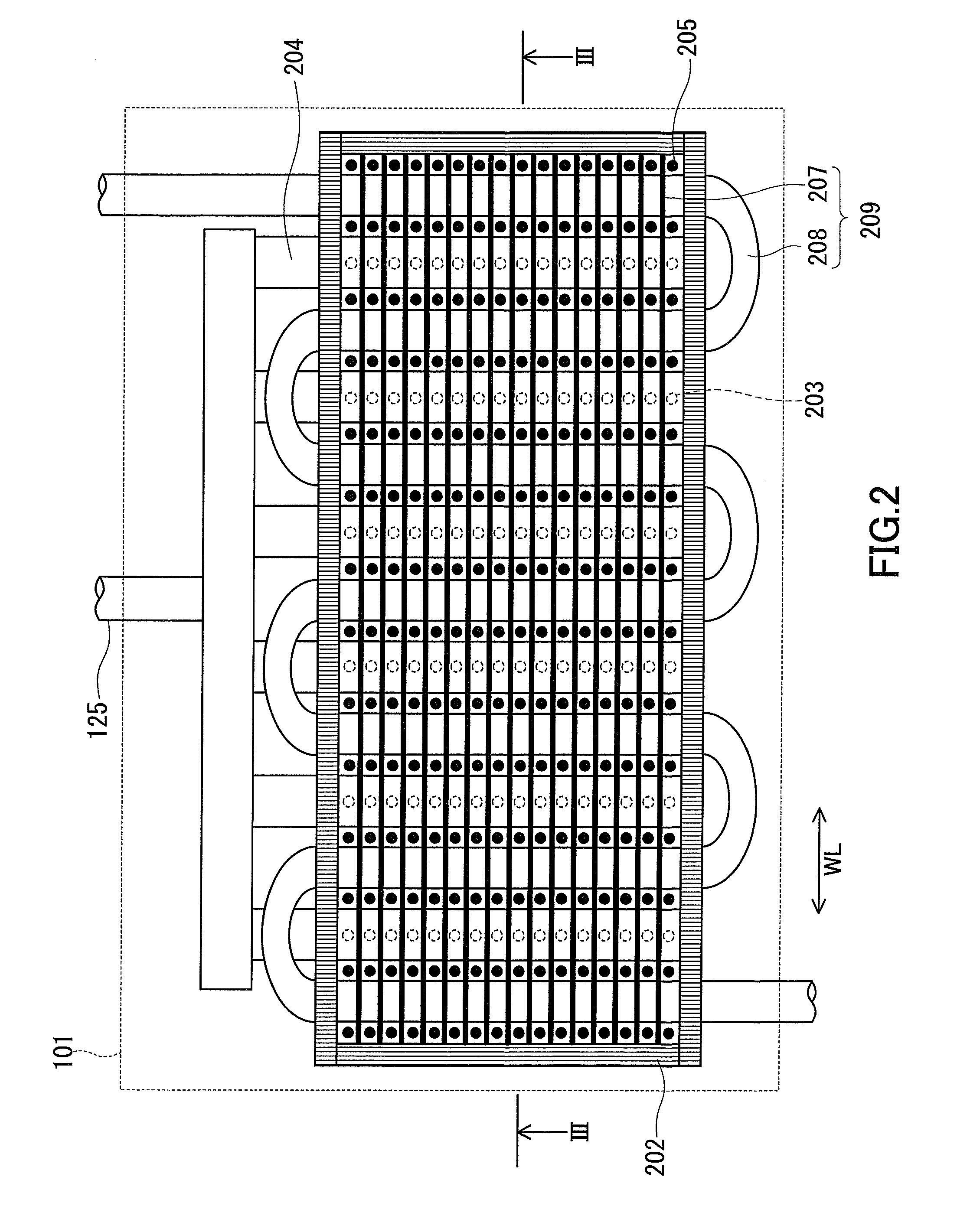

[0026]FIG. 1 is a schematic diagram illustrating a heat storage system according to one embodiment of the present invention. A heat storage system 100 is equipped with a heat pump 116, a heat storage circuit 121 and a heating medium circuit 122.

[0027]The heat pump 116 is equipped with a compressor 111, a heat radiator 112, an expander 113, a first evaporator 114 and a second evaporator 115. These equipments are connected by refrigerant pipes, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com