Heat exchange system

a technology of heat exchange system and heat exchange plate, which is applied in the direction of heating type, heating apparatus, domestic cooling apparatus, etc., can solve the problems of large wind resistance, affecting blowing effect, low efficiency, etc., and achieves small fluctuation in torsion, stable operation, and large rotational inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Further description of the invention will be given below in conjunction with specific embodiments and accompanying drawings.

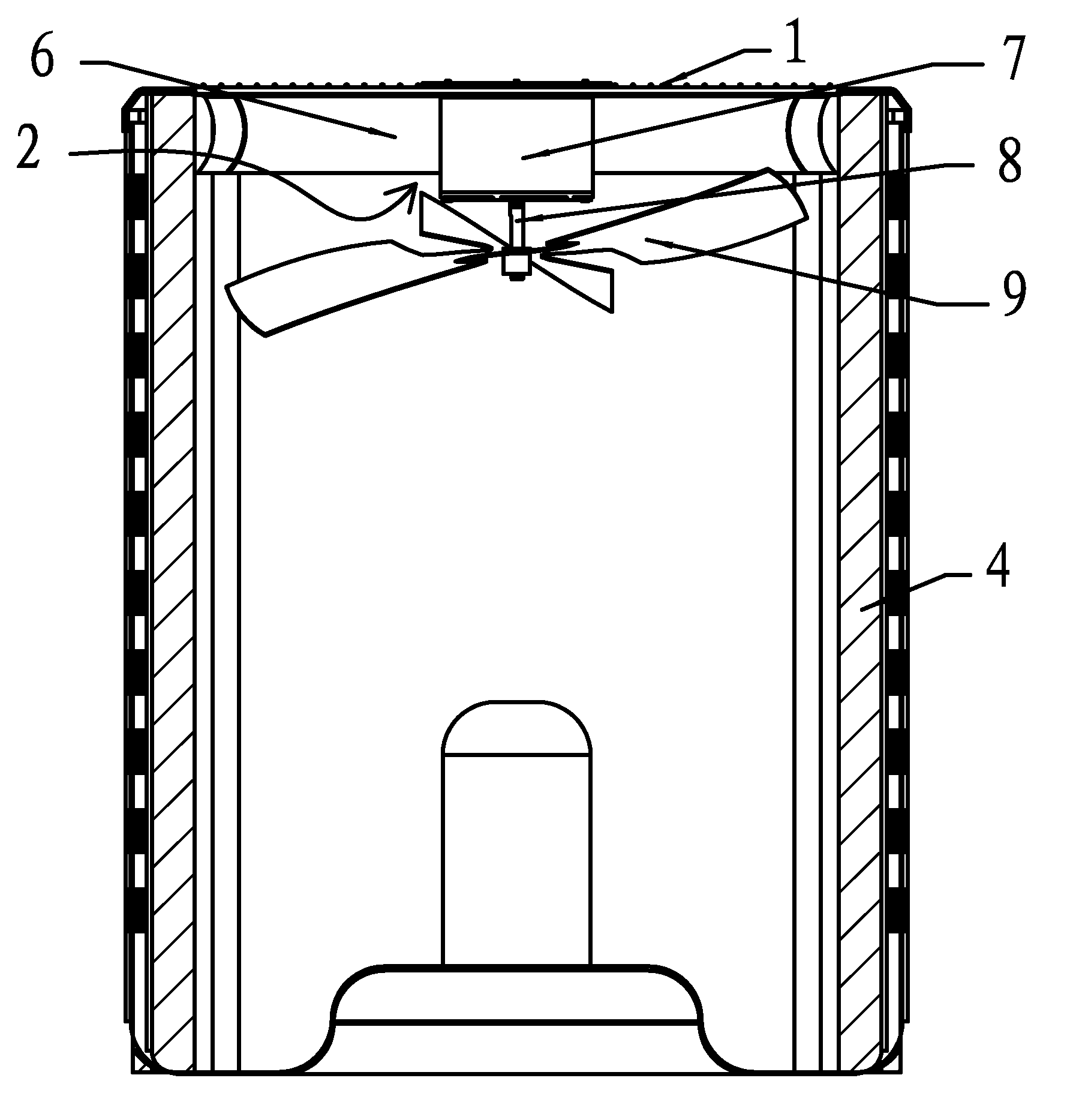

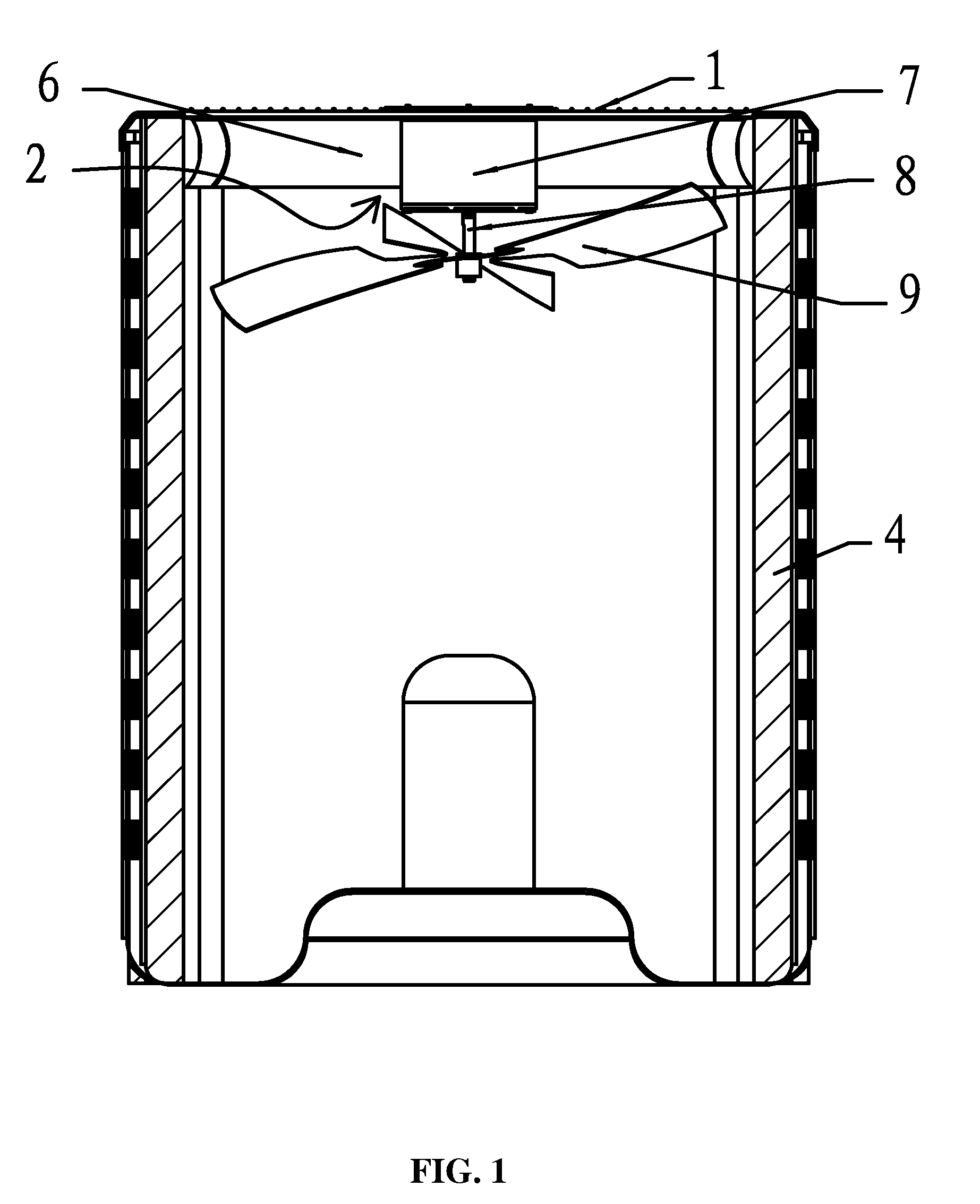

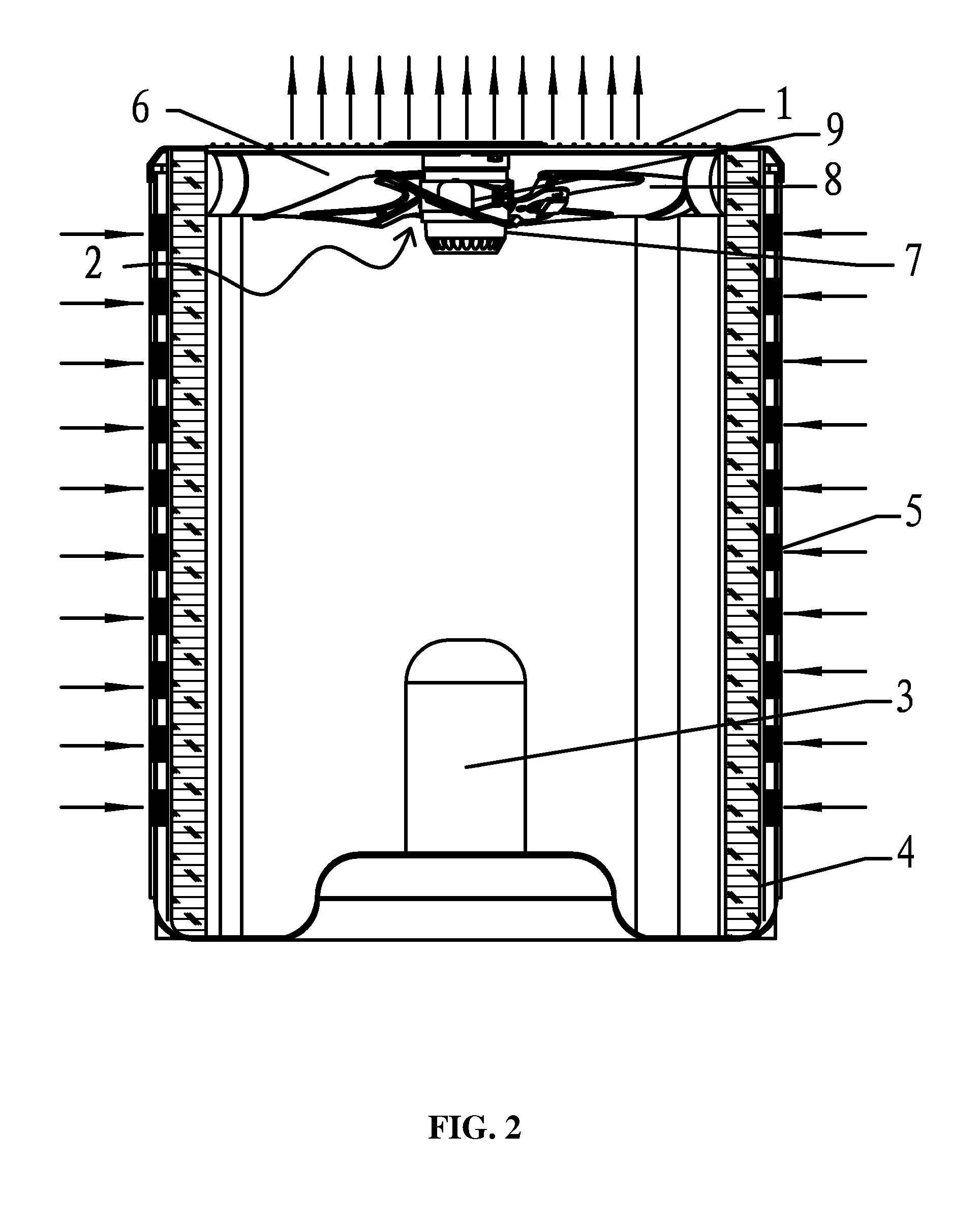

[0026]As shown in FIGS. 2, 3 and 4, a heat exchange system of the invention comprises multiple grids 1, a blower 2, a compressor 3, and a box 4 having multiple exhaust inlets 5 on the side thereof. The grid 1 is disposed at an exhaust outlet 6 of the box 4, the blower 2 is disposed in the box 4 and below the grid 1, the compressor 3 is disposed on bottom surface in the box 4. The blower 2 is an external rotor axial fan, and comprises an external rotor motor 7 and a wind blade 8, and the wind blade 8 is disposed outside a rotor 71 of the external rotor motor 7.

[0027]The wind blade 8 is disposed outside the rotor 71 of the external rotor motor 7 via a support 9, the support 9 comprises an annular cylinder 91, and multiple mounting feet 92 extending from the annular cylinder 91, the wind blade 8 is disposed on the mounting foot 92, and the annular cylinder 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com