Modular climate change tarp system

a technology of climate change and tarps, applied in the field of modular systems, can solve the problems of inconvenient installation, and inability to meet stringent requirements,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]Generally, the present invention provides a modular system for stand-alone portable management of heating, cooling, temperature maintenance, insulation, and vapour control.

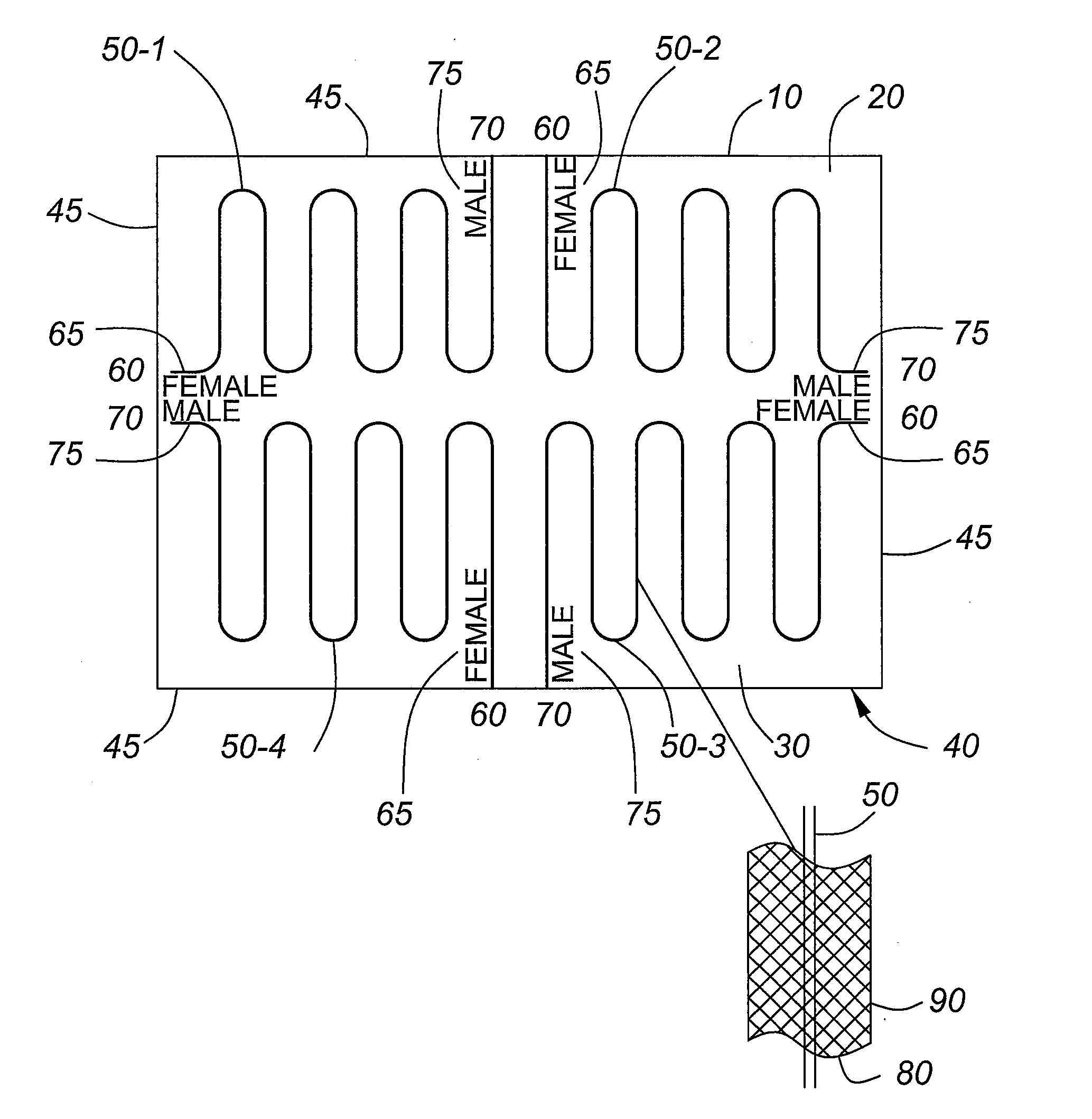

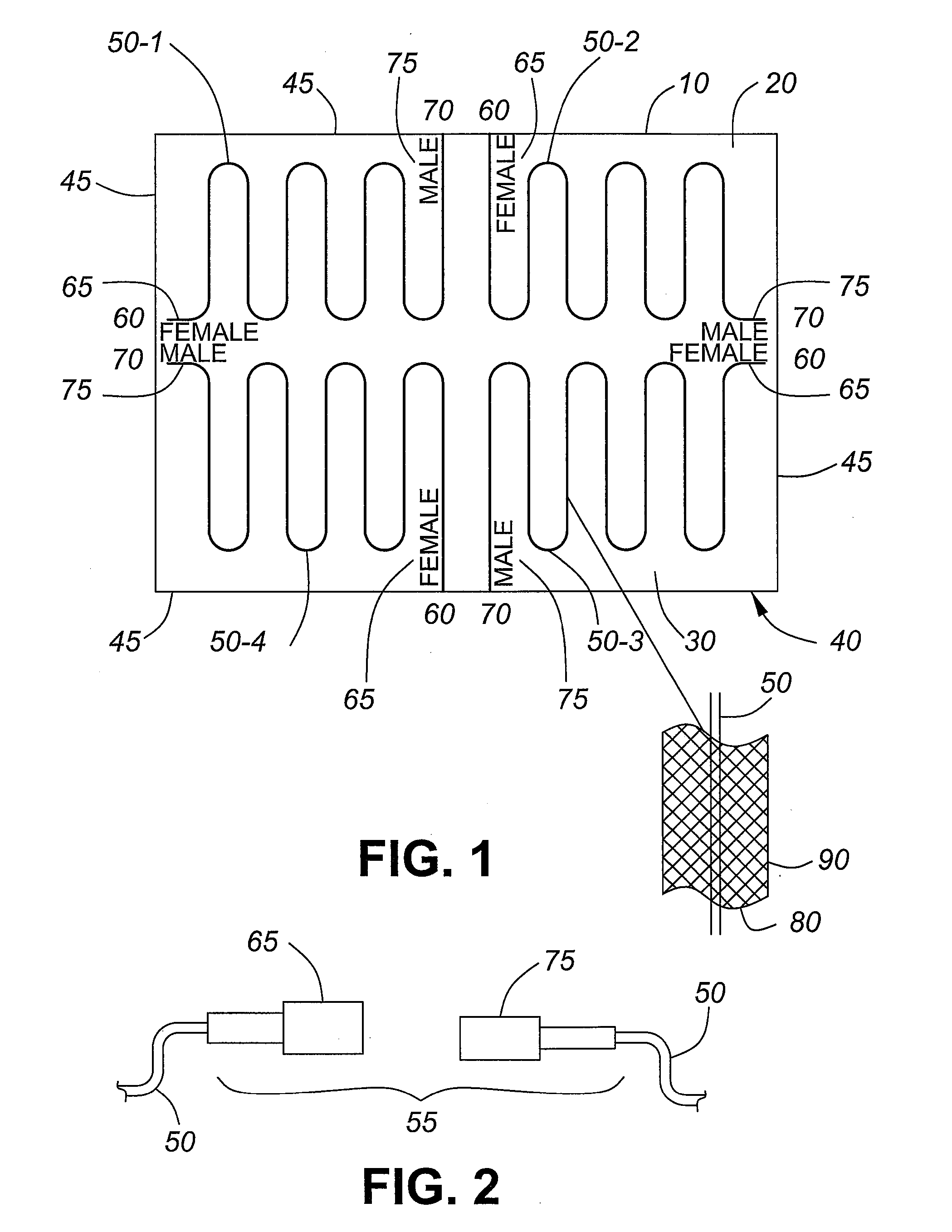

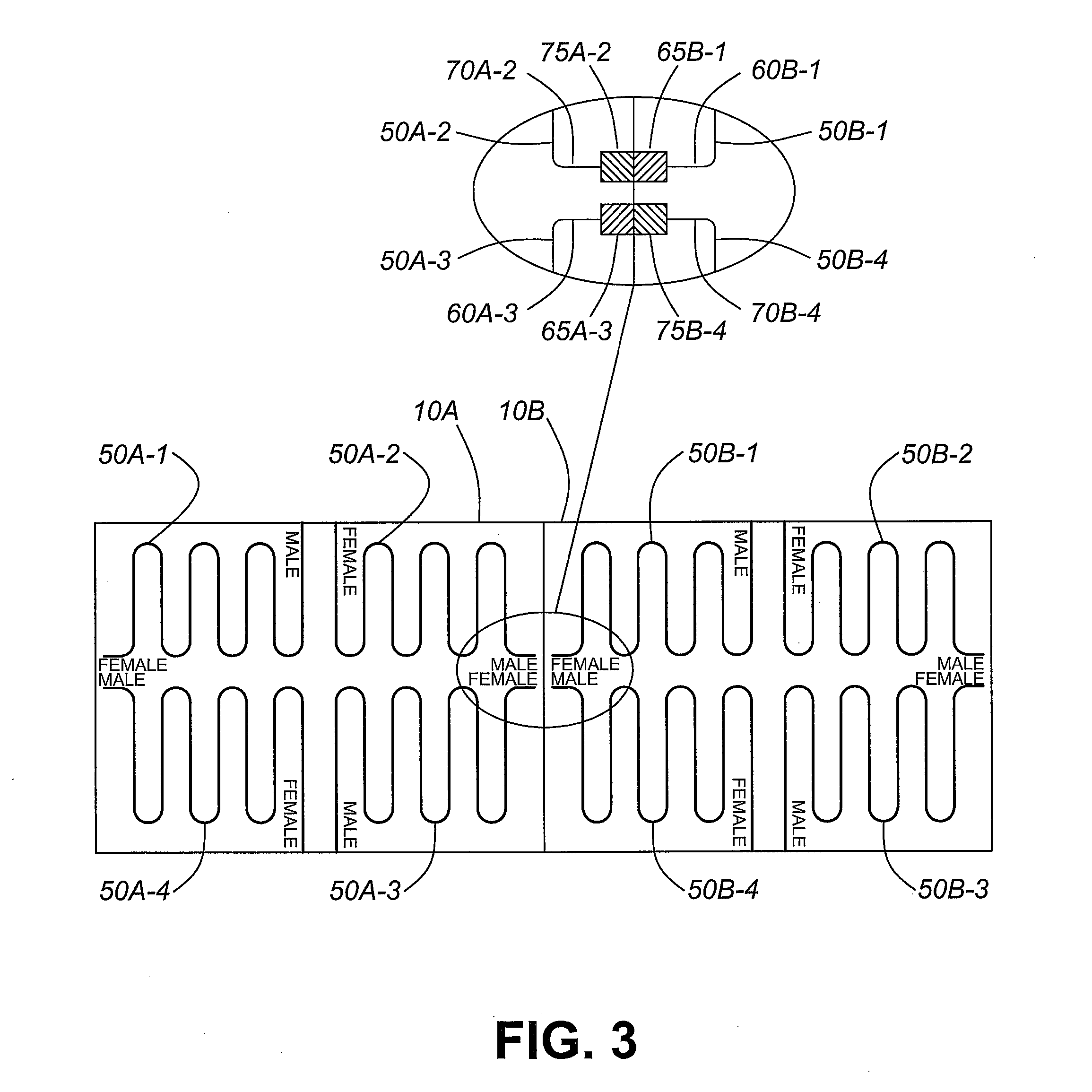

[0039]Referring to FIG. 1, a surface member 10 of the present invention includes a sheet 20 having a first side 30 and a second side 40. At least three thermal conduits 50 (four thermal conduits 50 shown as 50-1, 50-2, 50-3, and 50-4) extending from an inlet 60 at one edge 45 to an outlet 70 at an adjacent edge is attached to the first side 30 (shown), the second side 40 (not shown), or both the first side 30 and the second side 40 (not shown). The surface member 10 is a modular integration of the thermal conduit 50 and the sheet 20, and provide a variety of functions including heat transfer, insulation (heat transfer reduction or inhibition), and vapor barrier. The first side 30 or the second side 40 or both may be heat reflective, for example light colored, such as white, silver, or mirrored, or may be hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Thermal properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com