Refrigerating cycle device and air conditioner

a technology of refrigerating cycle and air conditioner, which is applied in the direction of refrigerating machines, lighting and heating apparatus, heating and refrigeration combinations, etc., can solve the problems of reducing the efficiency of the refrigerating cycle, and increasing the weight of the entire apparatus, so as to prevent deterioration, save energy, and ensure reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0021]An embodiment of the present invention will be described below referring to the attached drawings.

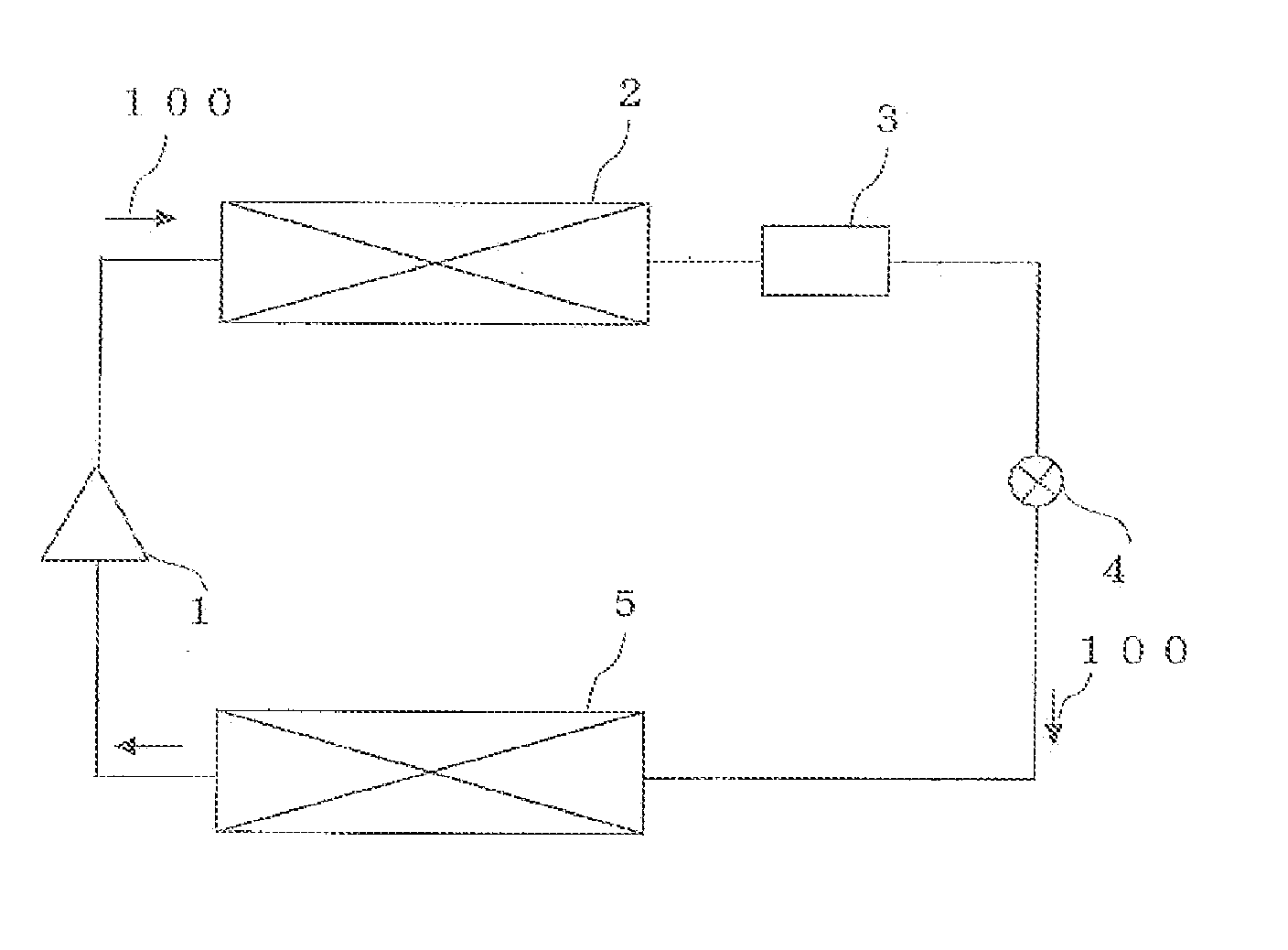

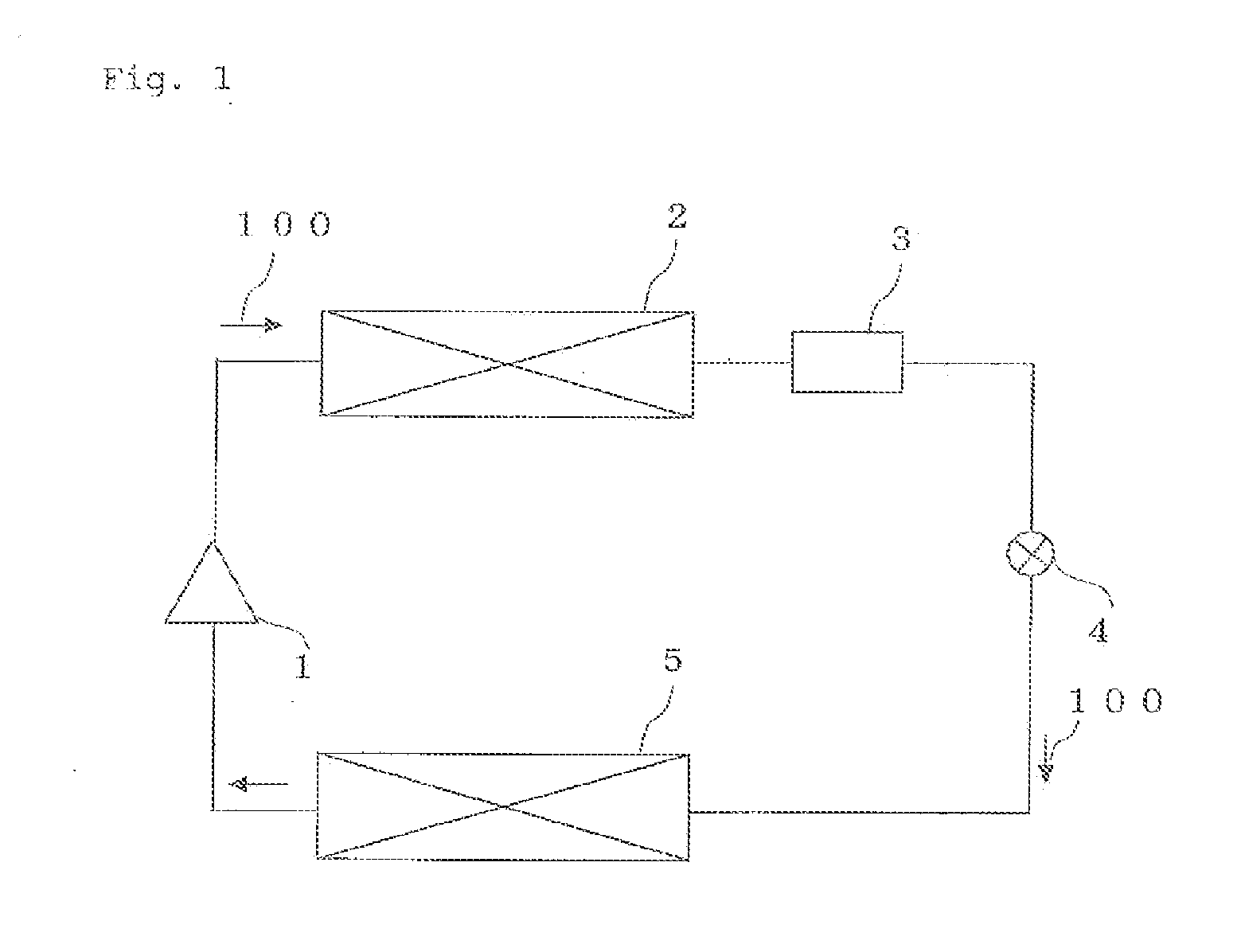

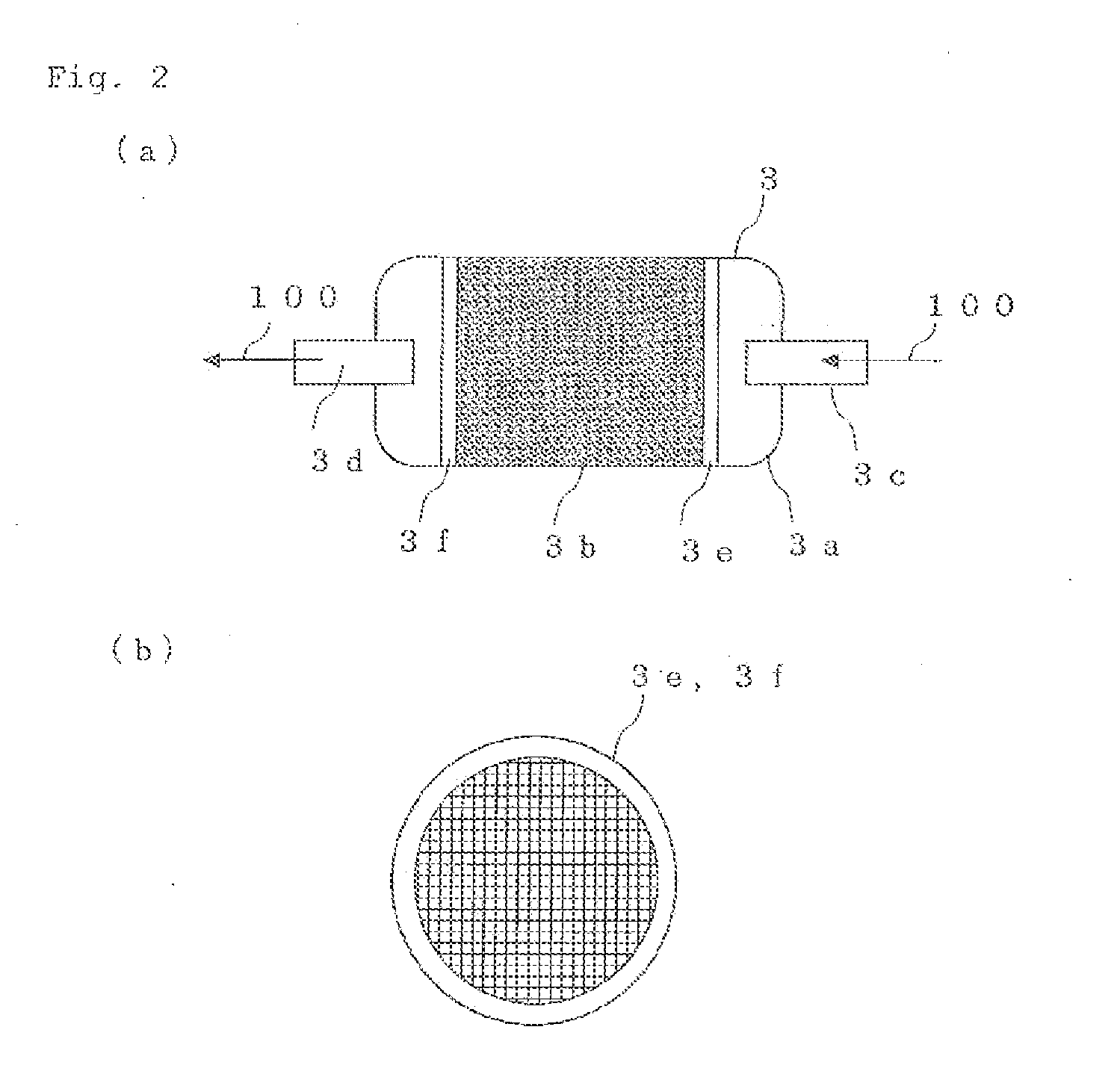

[0022]FIG. 1 is a diagram illustrating a basic configuration of a refrigerating cycle device according to Embodiment 1 of the present invention. Arrows 100 in FIG. 1 indicate a direction along which a refrigerant flows. In FIG. 1, the refrigerating cycle device has a compressor 1, a condenser 2, air adsorbing means 3, a throttle device (expansion valve) 4, and an evaporator 5. Each device (element part) is connected to each other by piping so as to constitute a refrigerant circuit, in the refrigerant circuit, a refrigerant, to be circulated is sealed. As the refrigerant, in this Embodiment, a refrigerant having a double bond in an atomic bond such as CF3CH ═CF2, CF3CF ═CF2 including an HFO refrigerant containing tetrafluoropropene (represented by CF3CF═CH2: 2,3,3,3-Tetrafluoropropene, HFO-1234yf) is sealed.

[0023]The compressor 1 sucks the refrigerant to be circulated through the r...

embodiment 2

[0042]FIG. 5 is a diagram illustrating a configuration of a refrigerating cycle device according to Embodiment 2 of the present invention. In FIG. 5, means and the like given the same symbols as those in FIG. 1 and toe like will be described sup that the operations and the like described in Embodiment 1 are performed. Air separating / removing means 11 is means for separating the refrigerant and air using a density difference between the liquid refrigerant and air. Thus, the air separating / removing means 11 needs to be installed where the refrigerant is in the liquid state. Thus, in FIG. 5, the air separating / removing means 11 is installed in a high-pressure liquid line between the condenser 2 and the throttle device 4. Here, in each diagram which will be described in this Embodiment, it is supposed that the upper side is an upward direction in the vertical direction, and the lower side is a downward direction in the vertical direction.

[0043]FIG. 6 is a diagram illustrating a section ...

embodiment 3

[0056]In the above Embodiments, the cases in which the air adsorbing means 3 and the air separating / removing means 11 are installed singularly in the refrigerant circuit (refrigerating cycle device) were shown, but the number of installation is not limited to one. Particularly, the air separating / removing means 11 may be provided at plural spots where air can be easily collected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com