Optical detection of planarization, breakthrough and end-point in membrane-mediated electropolishing of metal layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

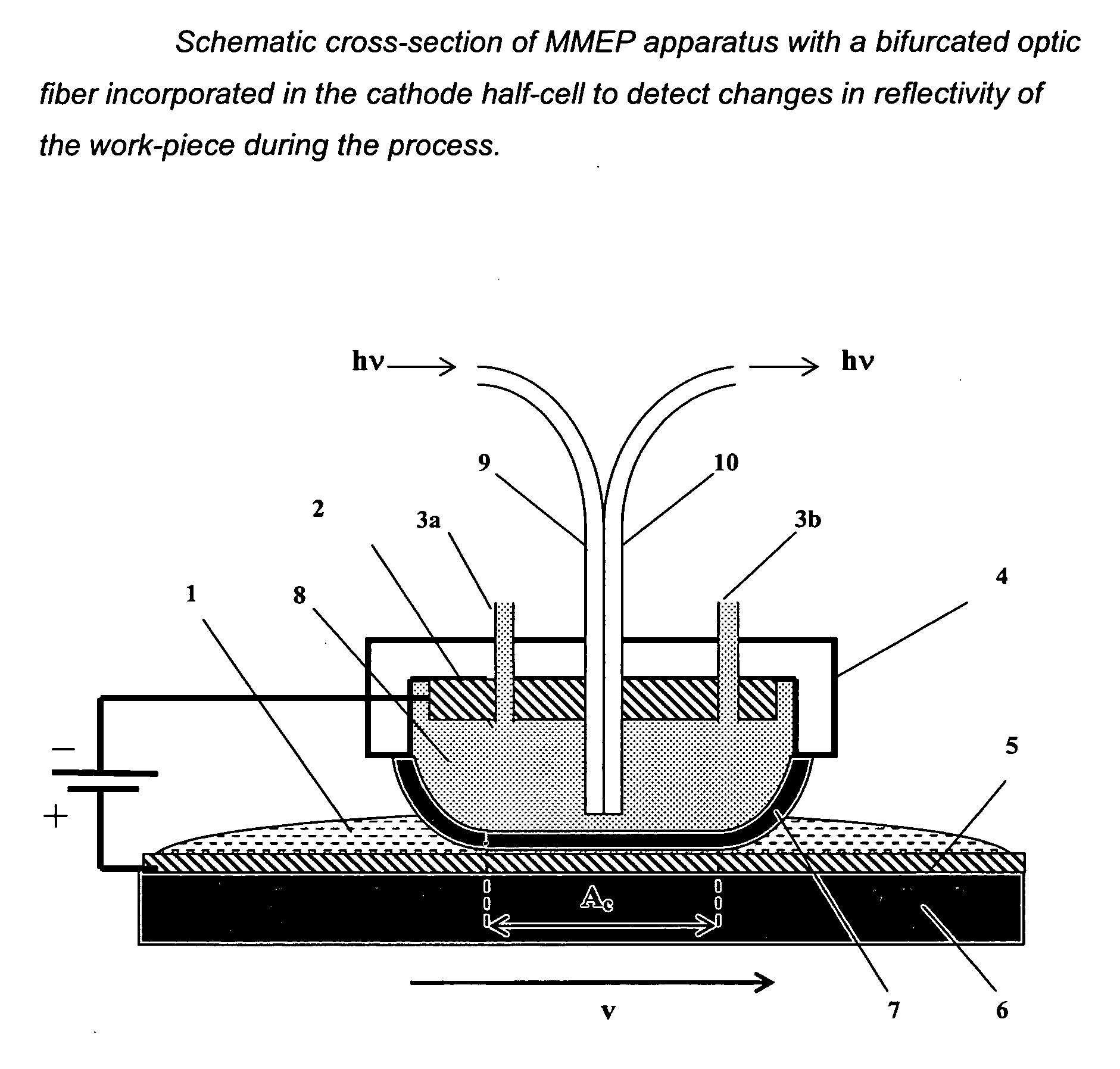

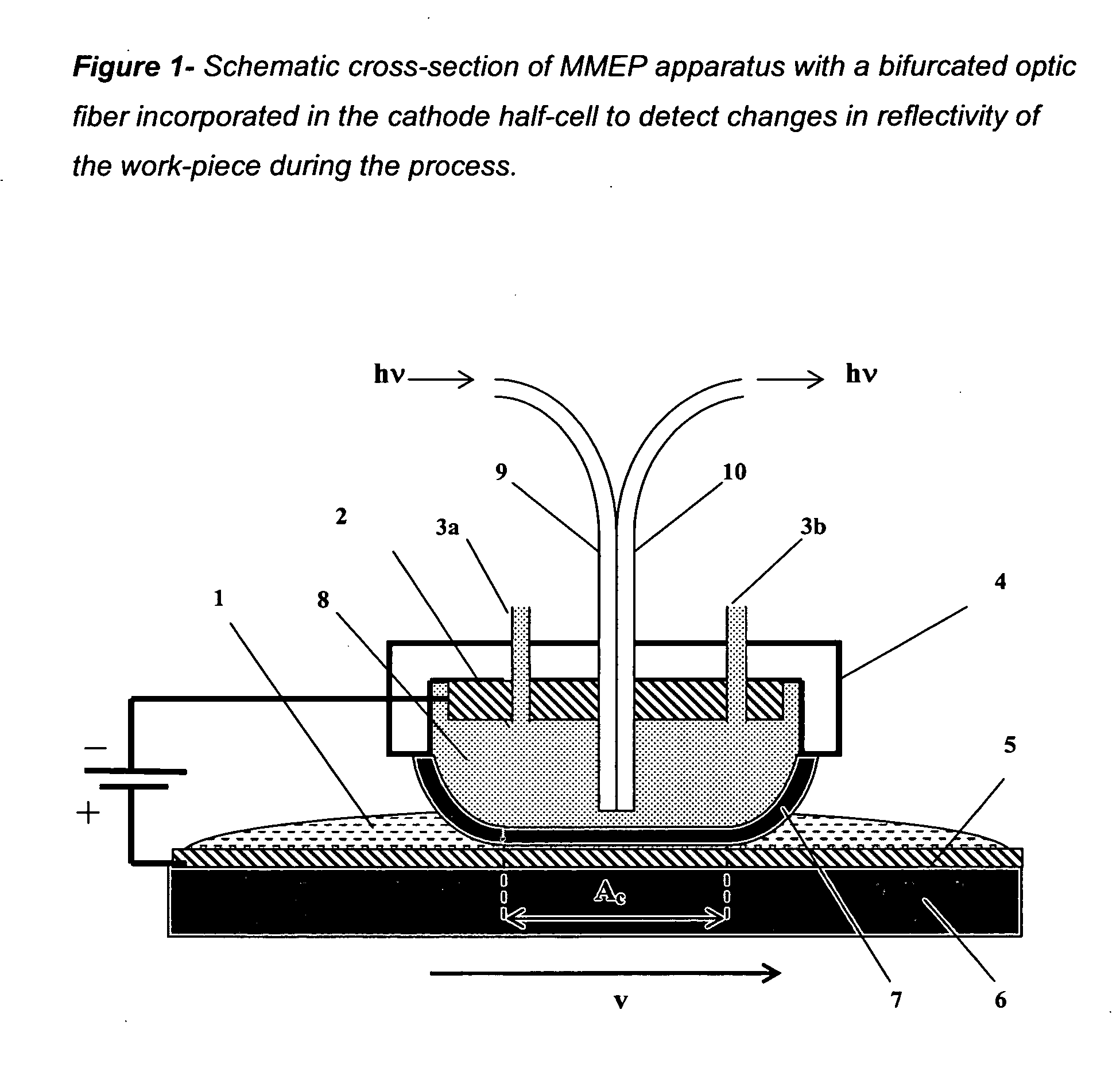

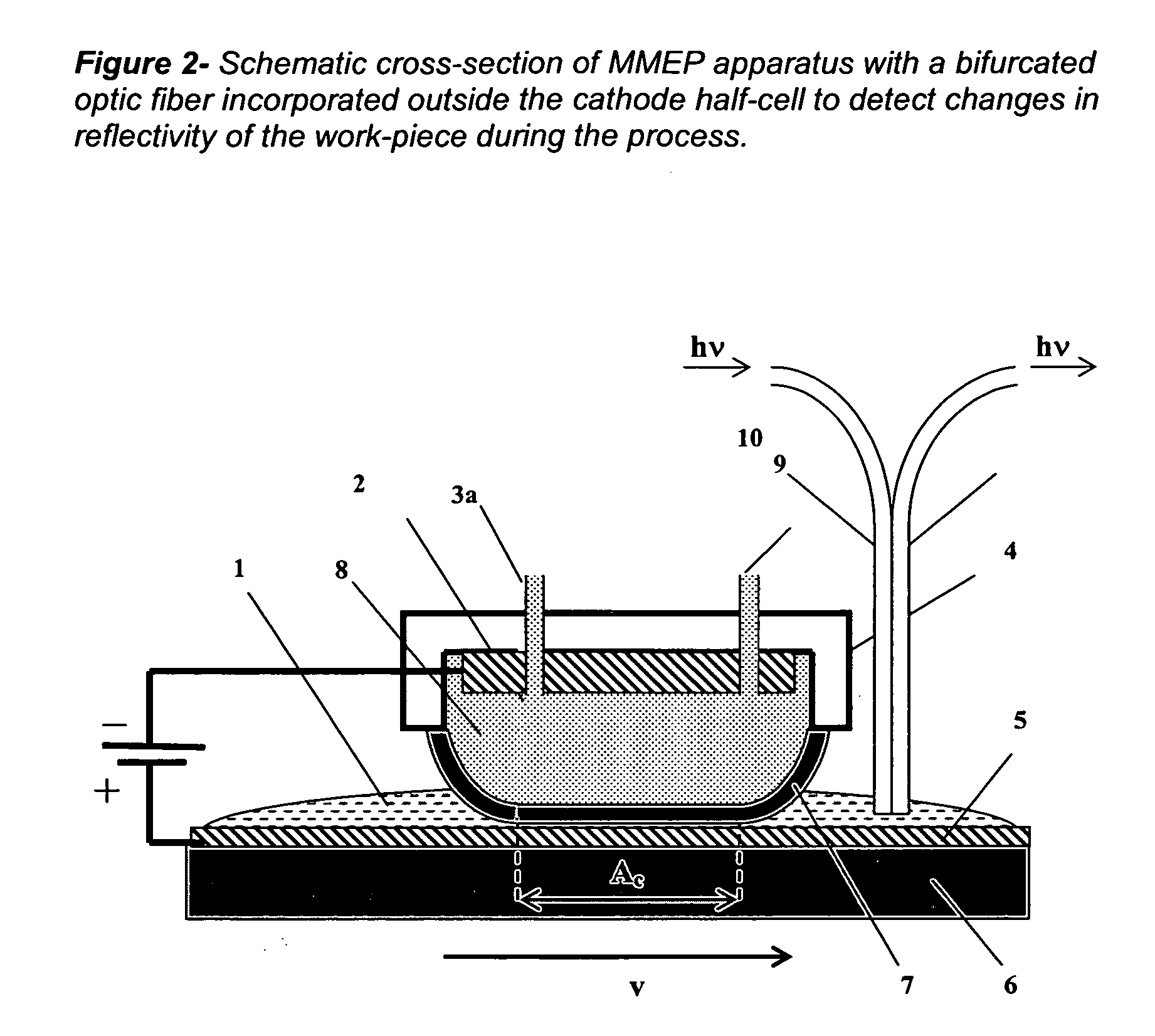

Embodiment Construction

[0020]This invention is directed to optical methods and apparatuses for detecting in situ changes in the topography of a work-piece during the progress of MMEP. The optical apparatuses and methods can be used to detect in situ the point of breakthrough, where a thin metal coating is first cleared from certain areas of a substrate. The apparatuses and methods can also be used to detect in situ the end-point, where a thin metal coating has been entirely removed from raised, plateau areas on the substrate surface, prior to removal by MMEP of the metal coating from recessed areas of the substrate.

[0021]In an MMEP process, the workpiece is physically separated from the electrolyte and cathode by a charge-selective ion-conducting membrane, wherein the membrane is essentially impermeable to the electrolyte but permeable to the ions produced by anodic oxidation of the work piece. MMEP is described in co-pending applications (U.S. Ser. No. 10 / 976,897; U.S. Ser. No. 10 / 986,048; and U.S. Ser. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com