Optical filters based on polymer asymmetric bragg couplers and its method of fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

I. The Embodiments of the Present Invention

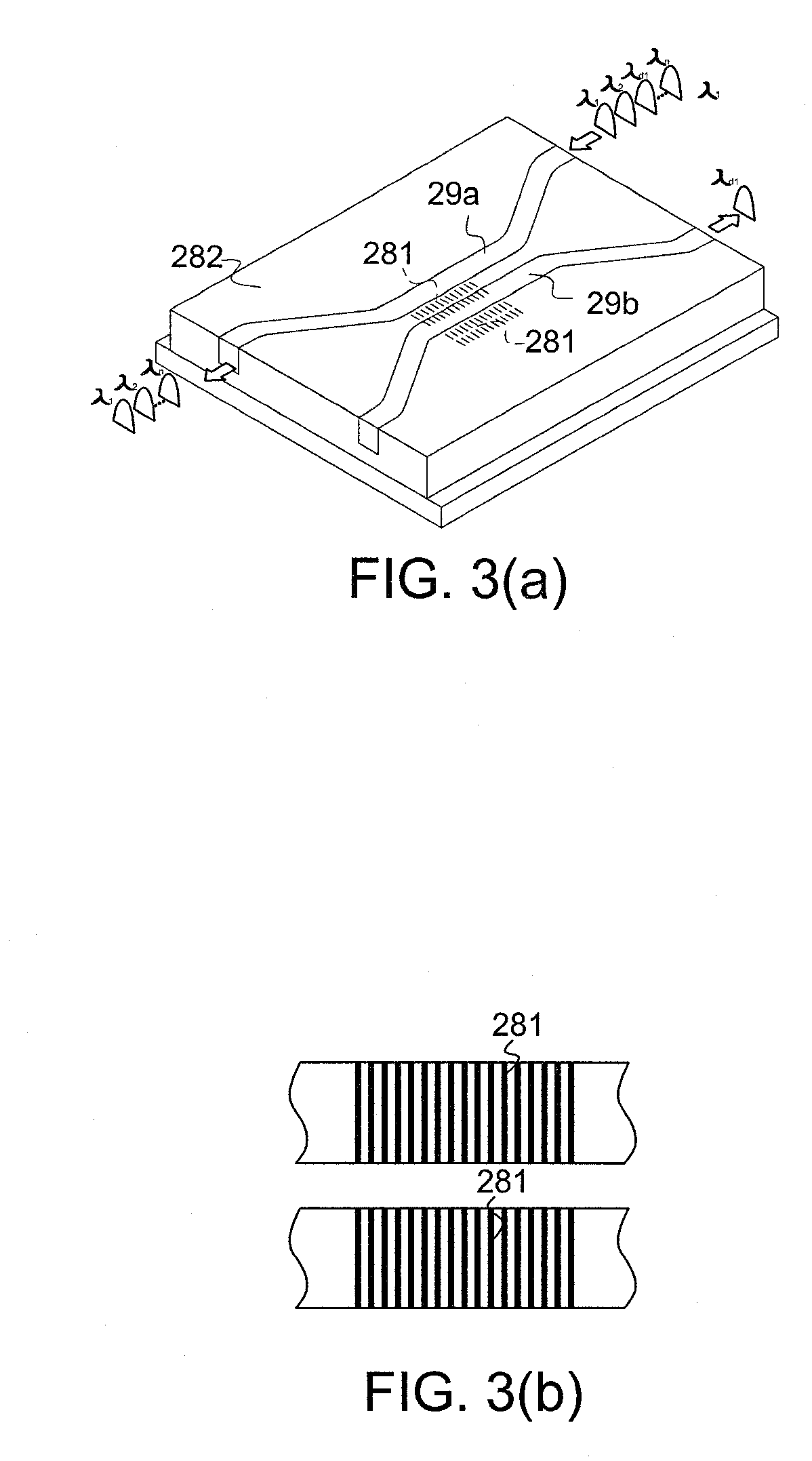

[0025]Referring to the FIGS. 1 to 6, the present invention discloses a method for fabricating optical filter based on polymer asymmetric bragg couplers.

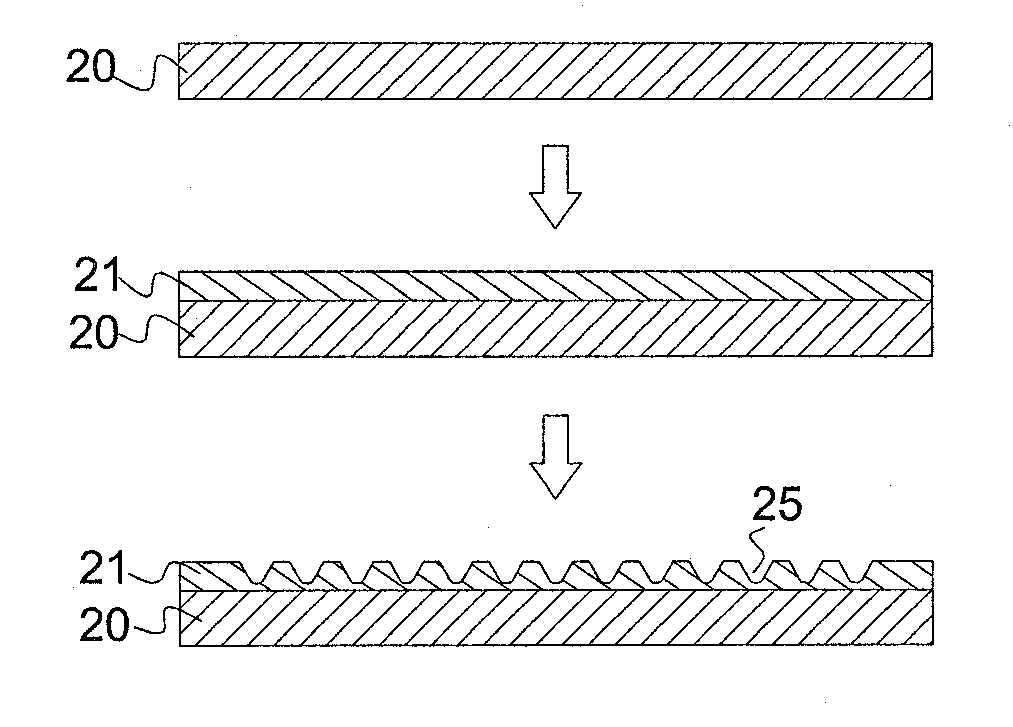

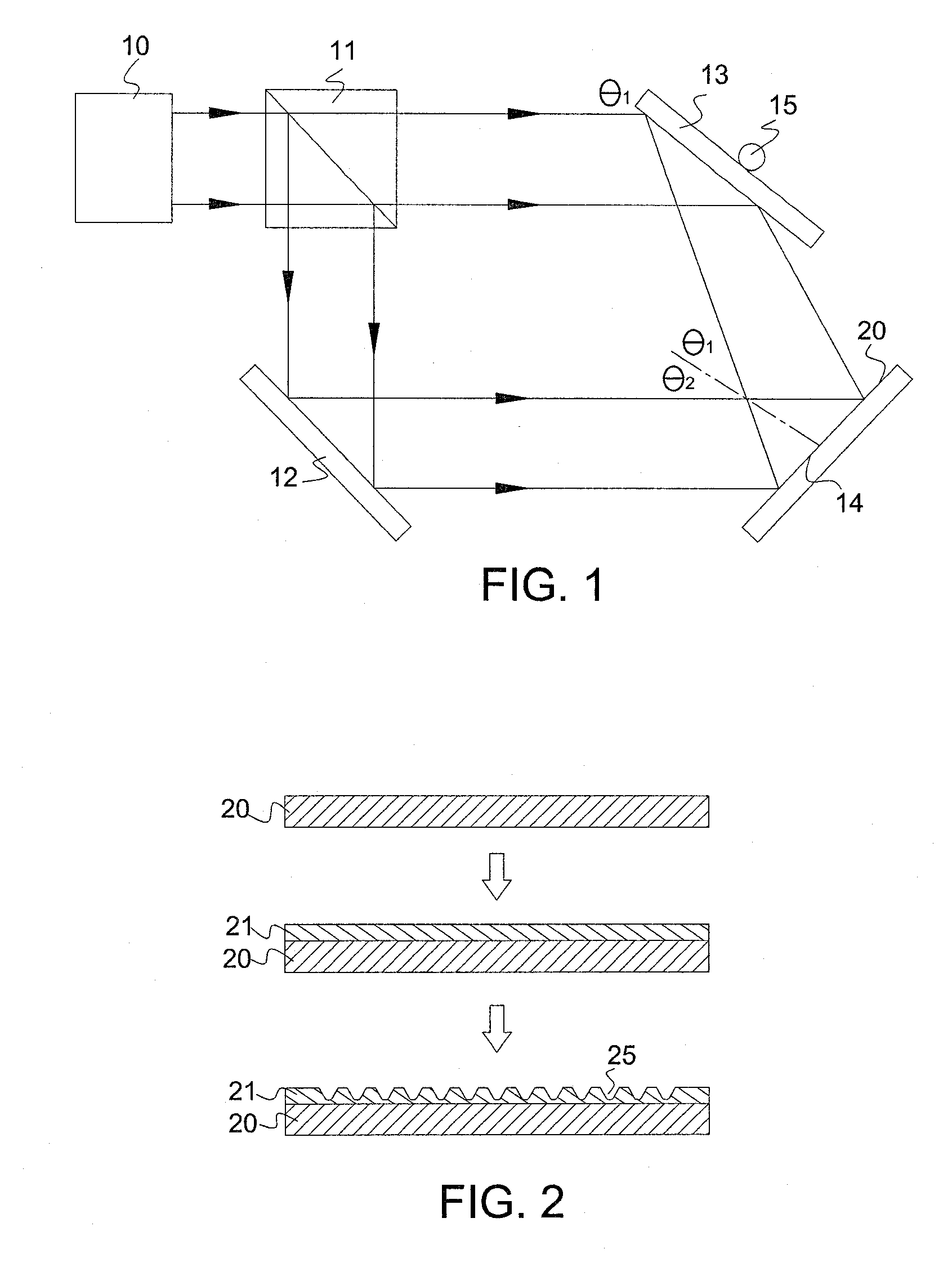

[0026]i. Grating Fabrication of the Present Invention

[0027]The fabrication method of the present invention, rapid prototyping of grating structures on a UV polymer substrate (preferably OG146 epoxy), involves a three-step process performed firstly. Referring to FIGS. 1 and 2, a positive photo-resister film 21 is coated on the OG146 epoxy substrate 20 by using a spin coater, wherein, the spin condition is 3000 rpm for 20 seconds and the thickness of the photo-resister film 21 is about 0.45 μm. A gratings pattern 210 is holographically exposed on the positive photo-resister film 21 by using a holographic interferometric apparatus 10 to produce a two-beam interference pattern (wherein, the photo-resister used in the invention is Ultra 123 made by MicroChem Corp., MA., whose refractive index is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com