Drain Bolt Mounting Structure

a technology of mounting structure and bolt, which is applied in the direction of lubricant filling/draining, shaft and bearing, lubrication element, etc., can solve the problems of bolt (b>12/b>) not being easily and efficiently mounted, and having a very low standard electrode potential and high electrical corrosion risk, so as to achieve a highly sealed state and facilitate and efficiently moun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Hereinafter, an embodiment of the present invention will be described with reference to the drawings. The stated directions are referenced from the perspective of a driver straddling a motorcycle, unless otherwise explicitly noted.

[Construction of Motorcycle]

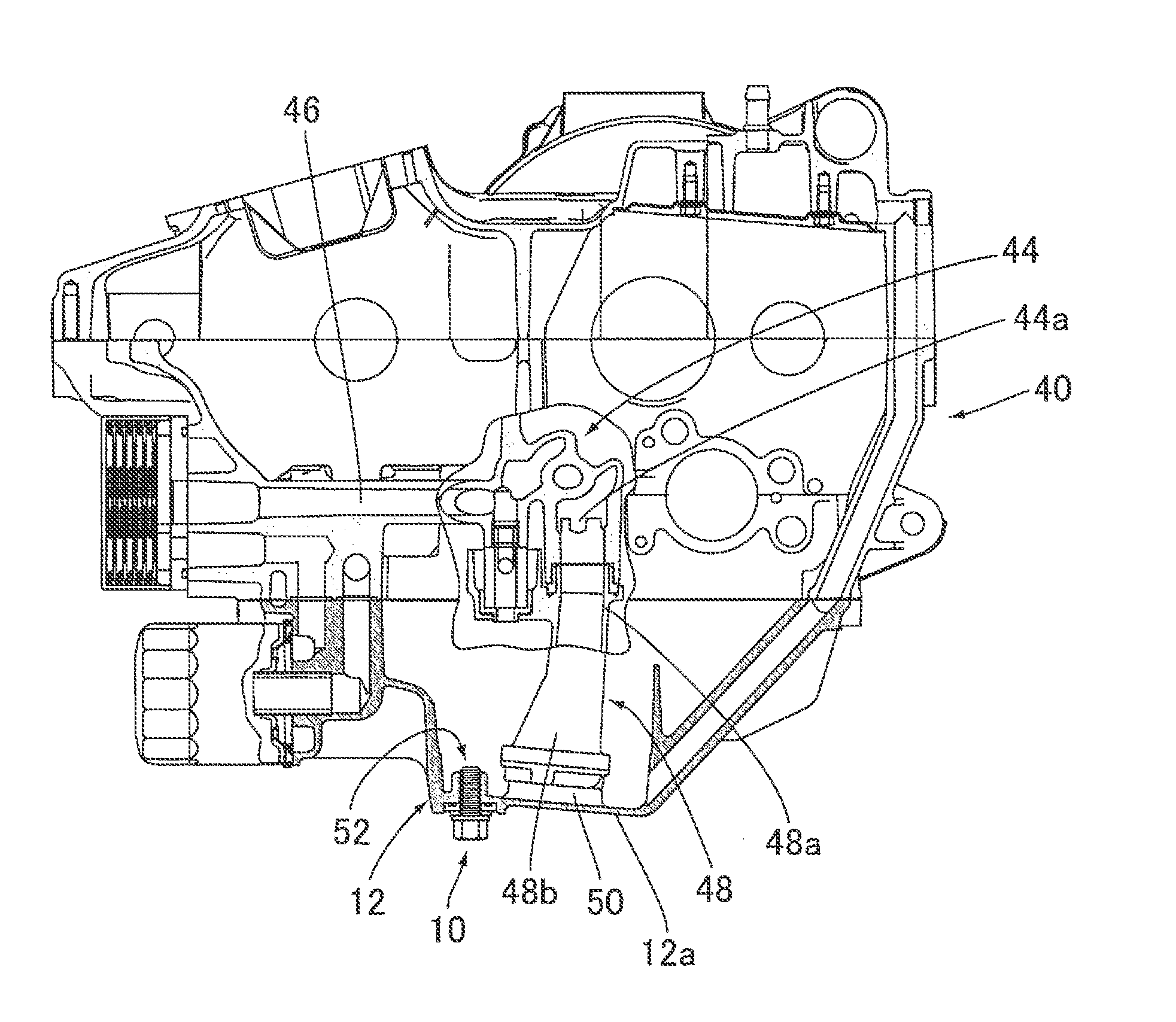

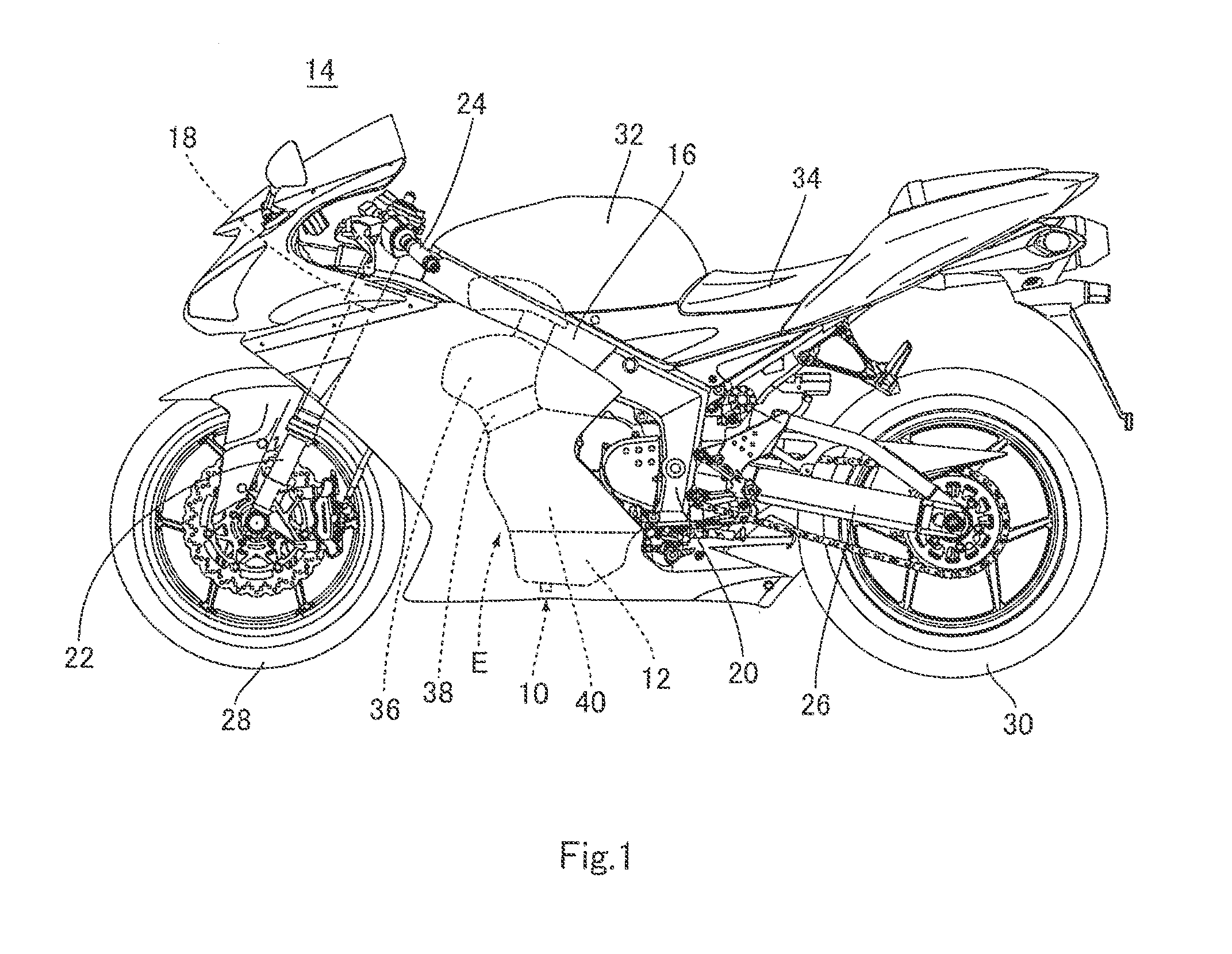

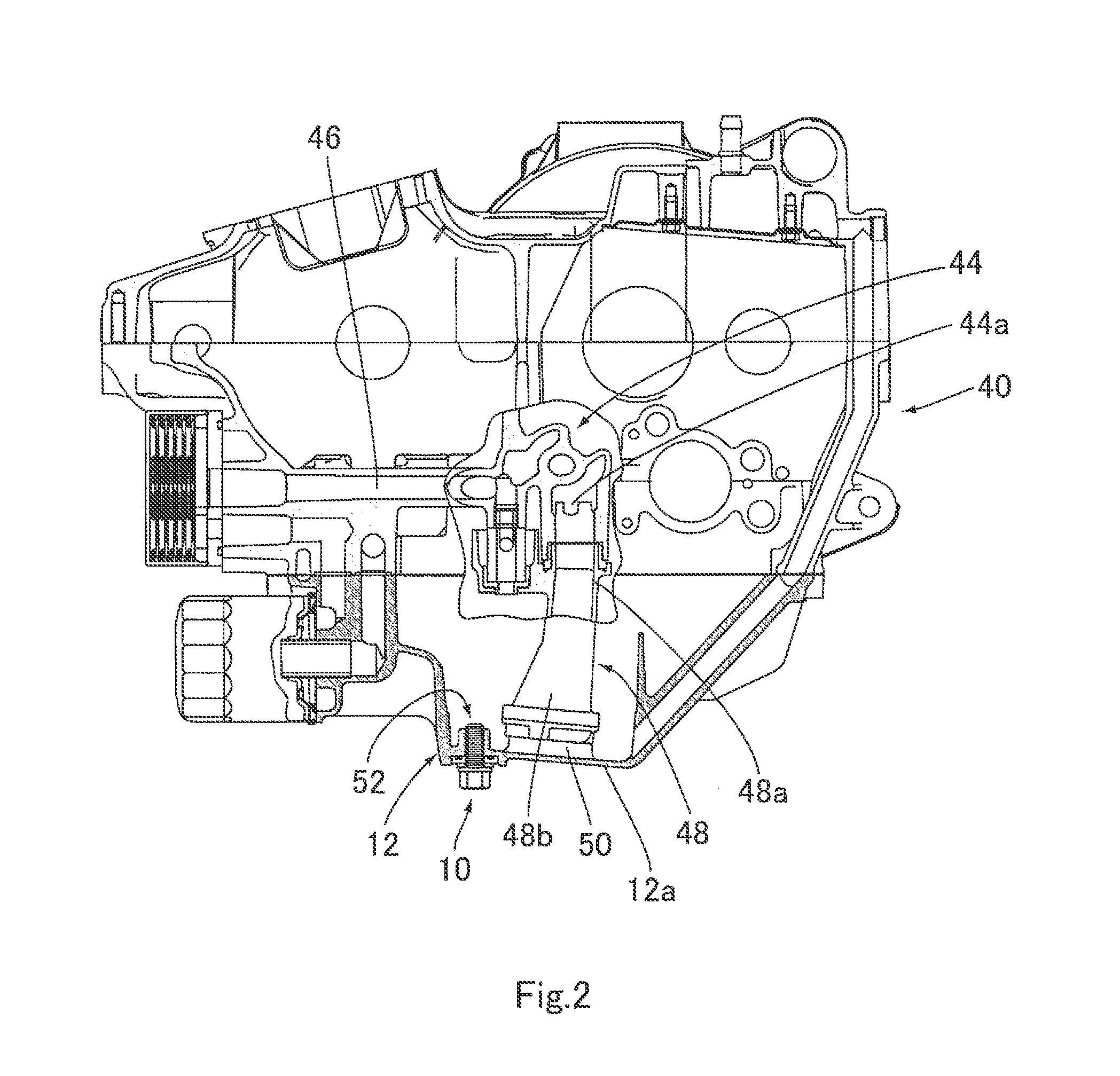

FIG. 1 is a left side view showing a construction of an entire motorcycle 14 including an oil pan 12 having a drain bolt mounting structure 10 according to the embodiment.

Referring now to FIG. 1, the motorcycle 14 includes a main frame member 16, a head pipe 18 provided at the front portion of the main frame member 16 and a pair of right and left pivot frame members 20 provided at the rear portion of the main frame member 16. A steering shaft (not shown) is rotatably inserted into the head pipe 18. A front fork 22 and a steering handle 24 are attached to the steering shaft. A pair of right and left swing arms 26 is attached to the pivot frame members 20, respectively. A front wheel 28 is mounted to the lower end portion of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com