Charging member, process cartridge and electrophotographic apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

exemplary embodiment 1

Production of Charging Member

[0121]An A-kneaded rubber composition was produced by mixing the raw materials shown in the following Table 1 with a 6-liter pressurizing kneader “TD6-15MDX” (which is trade name and is made by TOSHIN CO., LTD.) at a filling factor of 70 vol % and a blade rotation speed of 30 rpm, for 16 minutes.

TABLE 1Nitrile rubber (trade name: JSR N230SV, made by100partsJSR Corporation)Carbon black (trade name: TOKABLACK #7360SB,48partsmade by TOKAI CARBON CO., LTD.)Calcium carbonate (trade name: “NANOX#30”, made20partsby MARUO CALCIUM CO., LTD.)Bentonite (trade name: “BEN-GEL SH”, made by5partsHOJUN Co., Ltd.)Zinc oxide5partsZinc stearate1parts

[0122]A kneaded material I was obtained by adding a vulcanizing accelerator and a vulcanizing agent shown in the following Table 2 to the above described A-kneaded rubber composition; cutting back the mixture to right and left 20 times in total, with an open roll having a roll diameter of 12 inches at a front roll rotation spee...

exemplary embodiments 2 to 5

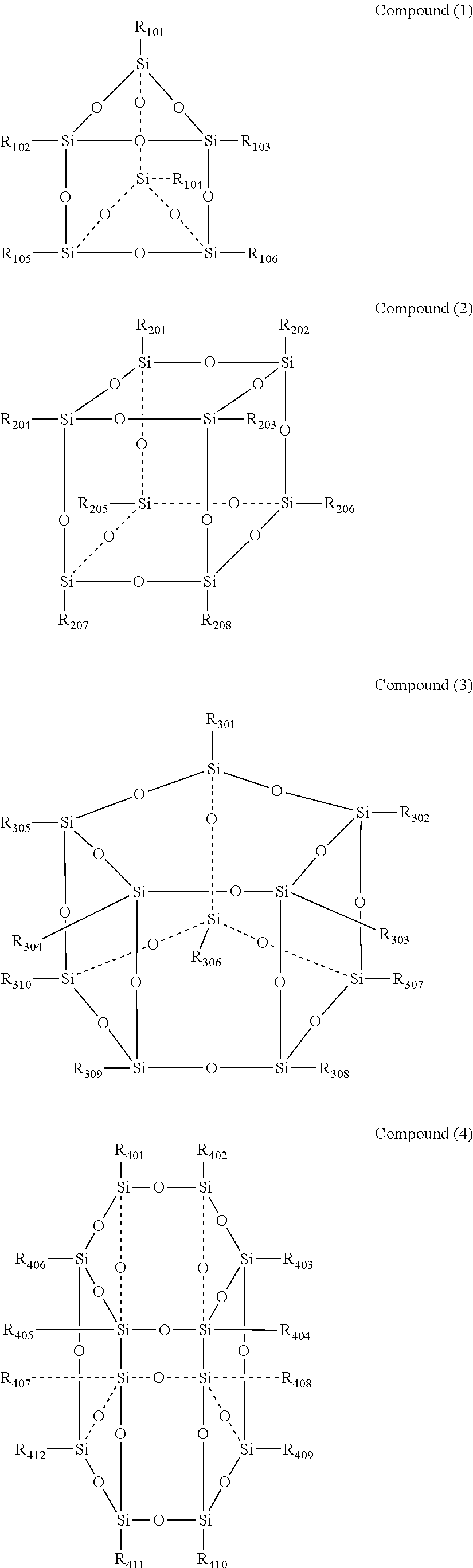

[0131]Charging rollers 2 to 5 were produced by the same method as in Exemplary Embodiment 1 except that the silsesquioxane No. 1 of Exemplary Embodiment 1 was changed to silsesquioxanes No. 2 to No. 5 shown in the following Table 4.

TABLE 4SilsesquioxaneNo.2Product number: 59397-4, made by Sigma-AldrichJapan K.K.3Product number: FL0583, made by Tomen PlasticsCorporation4Product number: 47765-6, made by Sigma-AldrichJapan K.K.5Product number: 56035-9 (T8), made by Sigma-Aldrich Japan K.K.

exemplary embodiment 6

[0132]A charging roller 6 was produced by the same method as in Exemplary Embodiment 1 except that the silsesquioxane No. 1 of Exemplary Embodiment 1 was changed to a silsesquioxane No. 6 which was produced in the following Synthesis Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com