Tension Leg Platform With Improved Hydrodynamic Performance

a technology of tlp and hydrodynamic performance, which is applied in the direction of special-purpose vessels, vessel construction, transportation and packaging, etc., can solve the problems of limited heave, roll and pitch motion of the platform, insufficient stability of the tlp (conventional or extended), and inability to achieve asymmetrical lateral flexion, improve the hydrodynamic performance of the platform, and reduce the support span and cantilever

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]U.S. Pat. No. 7,140,317, issued to Wybro et al. on Nov. 28, 2006 and entitled “Central Pontoon Semisubmersible Floating Platform,” is incorporated herein by reference in its entirety.

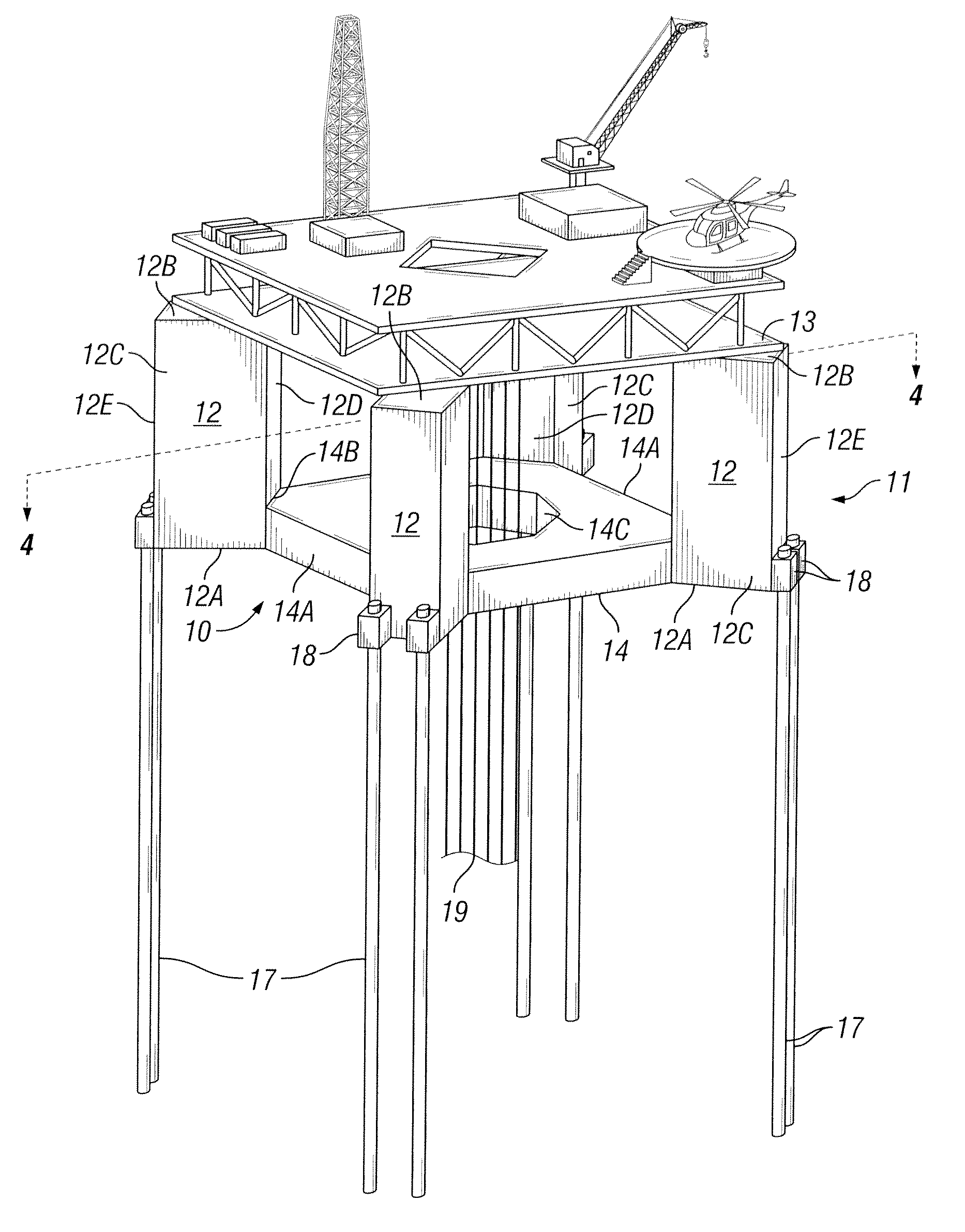

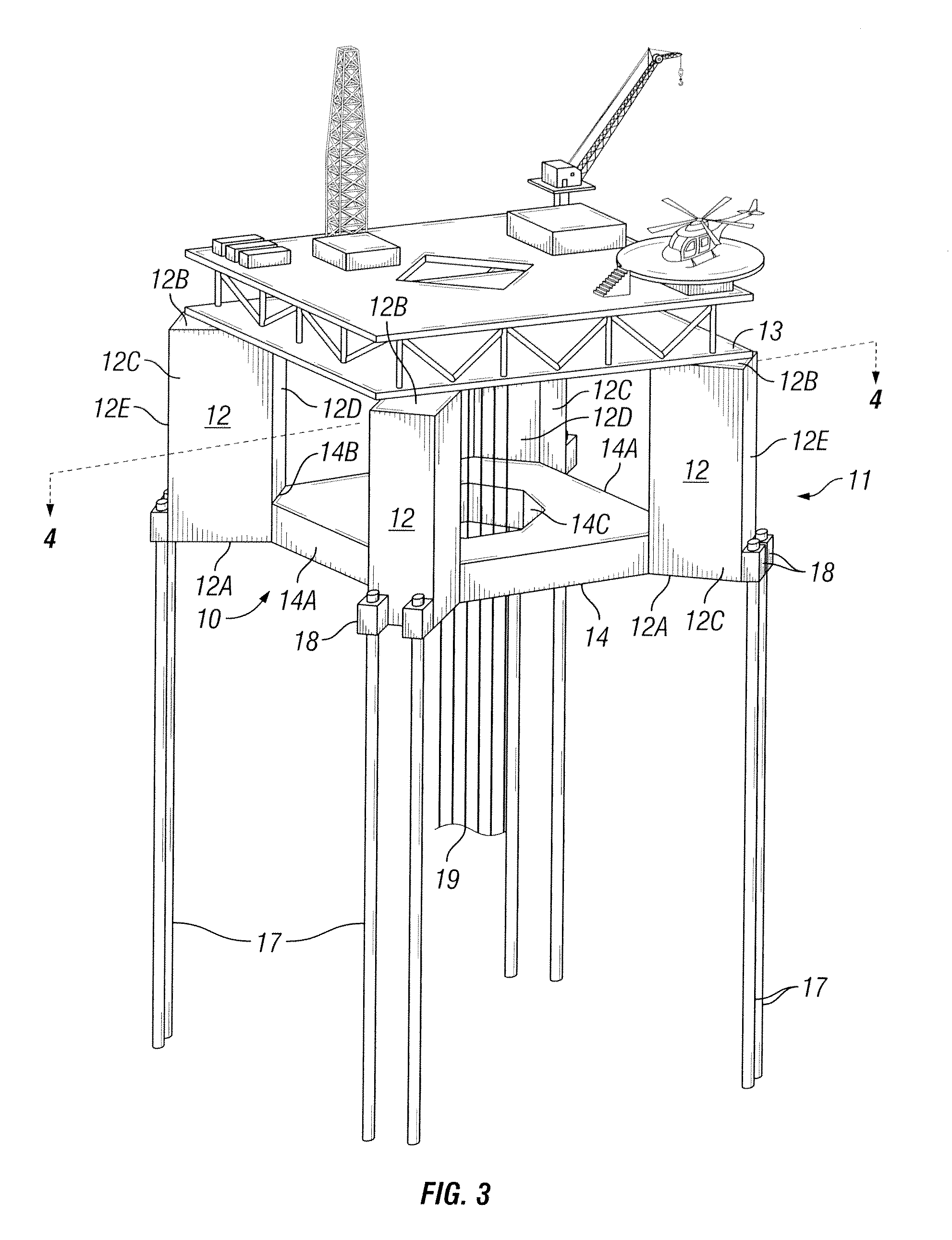

[0036]FIGS. 3 and 4 show a tension leg platform 10 according to a preferred embodiment of the invention for use in offshore applications, such as for offshore oil and gas drilling and production. The platform 10 has a hull 11 including vertical support columns 12 and a central pontoon structure 14 disposed inboard of the columns at a lower end thereof. TLP 10 includes a deck structure 13 supported by the upper ends of the columns 12.

[0037]The interior of both the columns 12 and the pontoon structure 14 is preferably subdivided by structural bulkheads (not illustrated) to strengthen the structure, to provide enclosed spaces for locating and storing various equipment (e.g., anchors, chains, propulsion mechanisms, etc.), and to provide a plurality of separate tanks for purposes of ballasting the vess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com