Variable valve device and method of controlling the same

a variable valve and valve control technology, applied in electrical control, machines/engines, non-mechanical valves, etc., can solve the problems of inability to maintain the open state of the air intake valve with a desired degree of opening, inability to prevent the sliding operation of the spool when the variable valve control is being performed, and the initial operation is unstable. , to achieve the effect of smooth sliding, preventing the delay in the sliding operation of the spool when the variable valve control is being performed, and preventing the delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]An embodiment of a variable valve device and a method of controlling the variable valve device according to the present invention will be described in detail below in reference to the accompanying drawings.

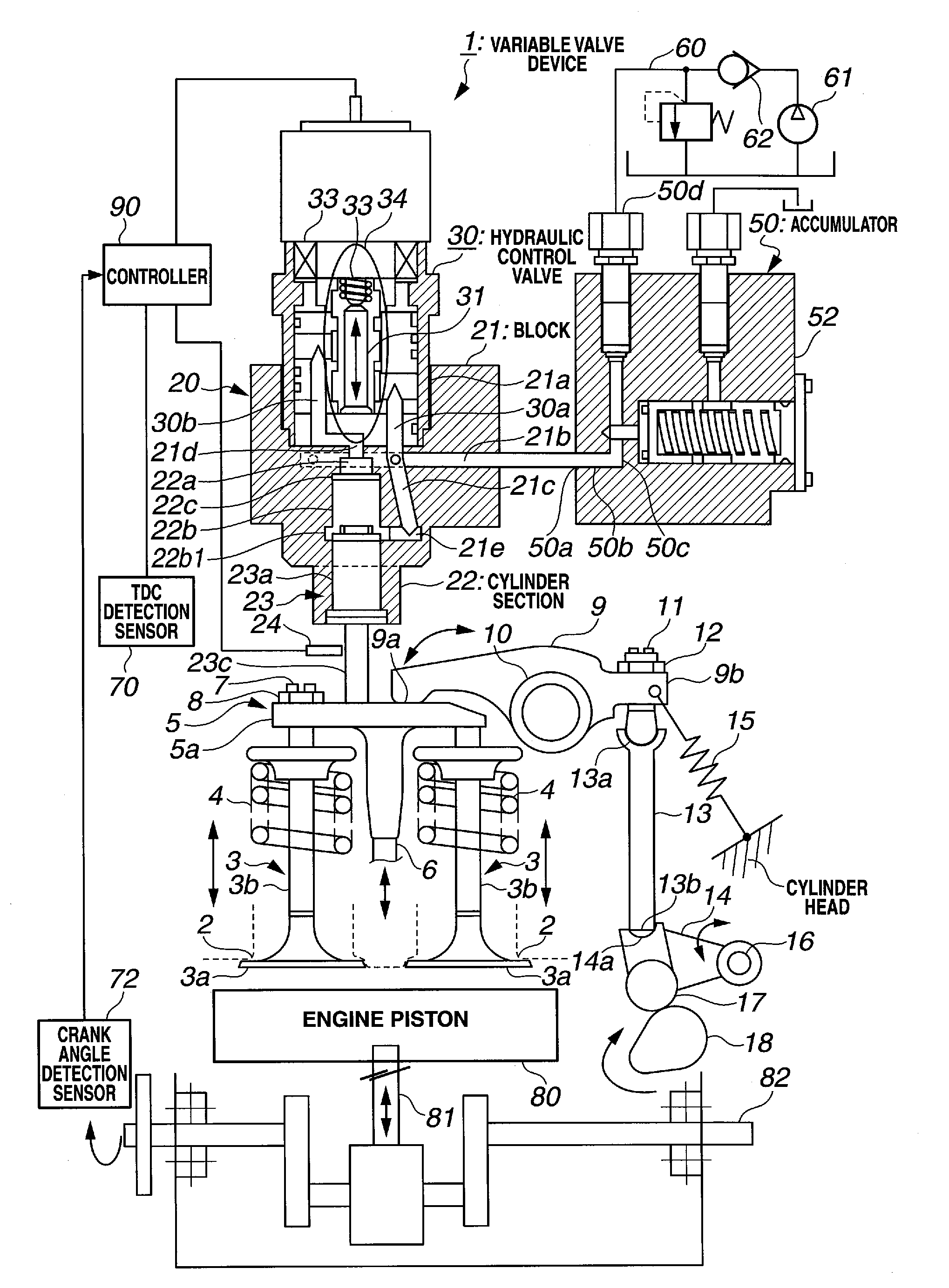

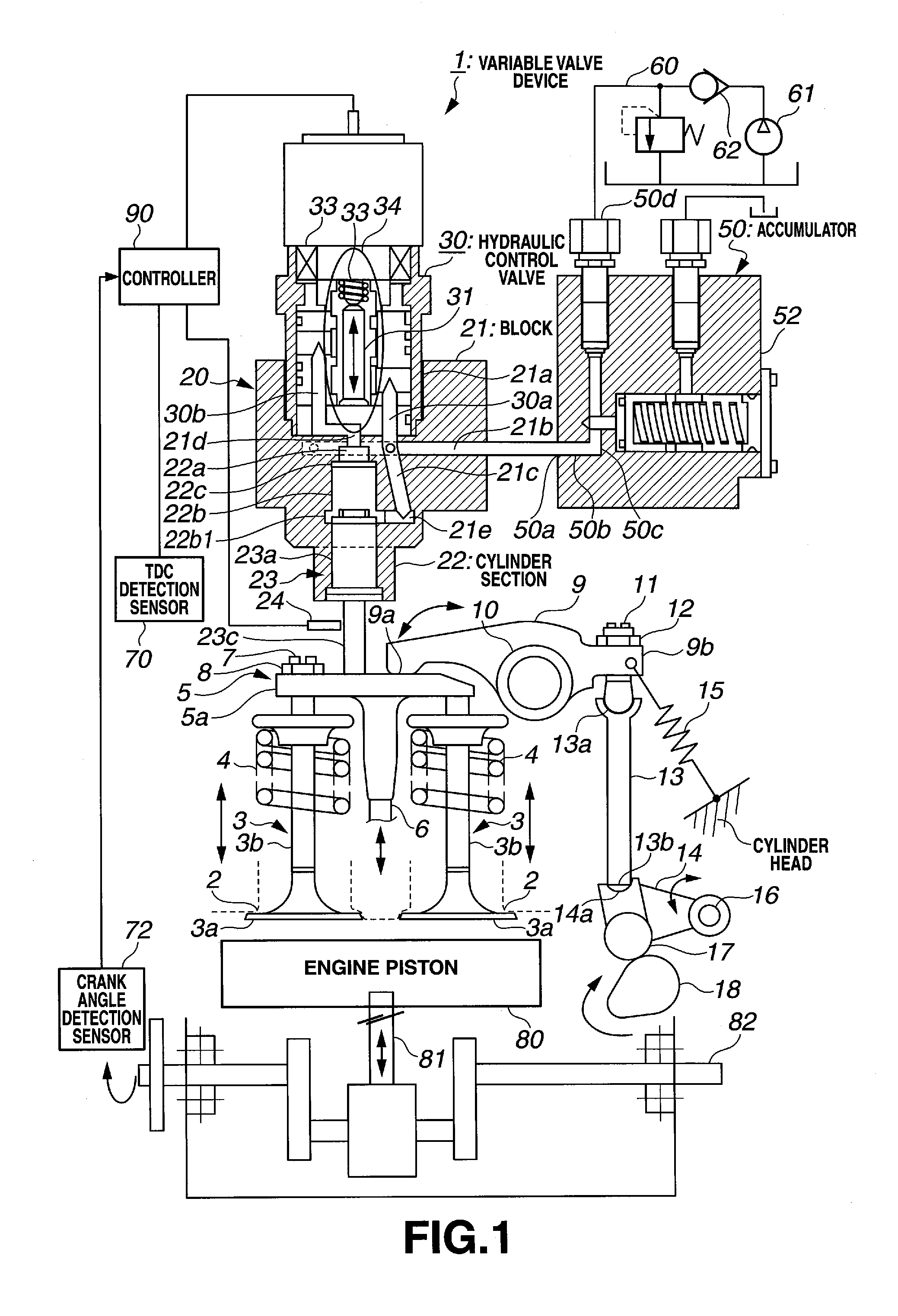

[0039]FIG. 1 a schematic diagram illustrating a variable valve device 1 according to the present invention. Although it is supposed in this embodiment that the variable valve device 1 is applied to a four-cycle diesel engine, and description of this embodiment will be made accordingly, a variable valve device according to the present invention is not limited to this embodiment.

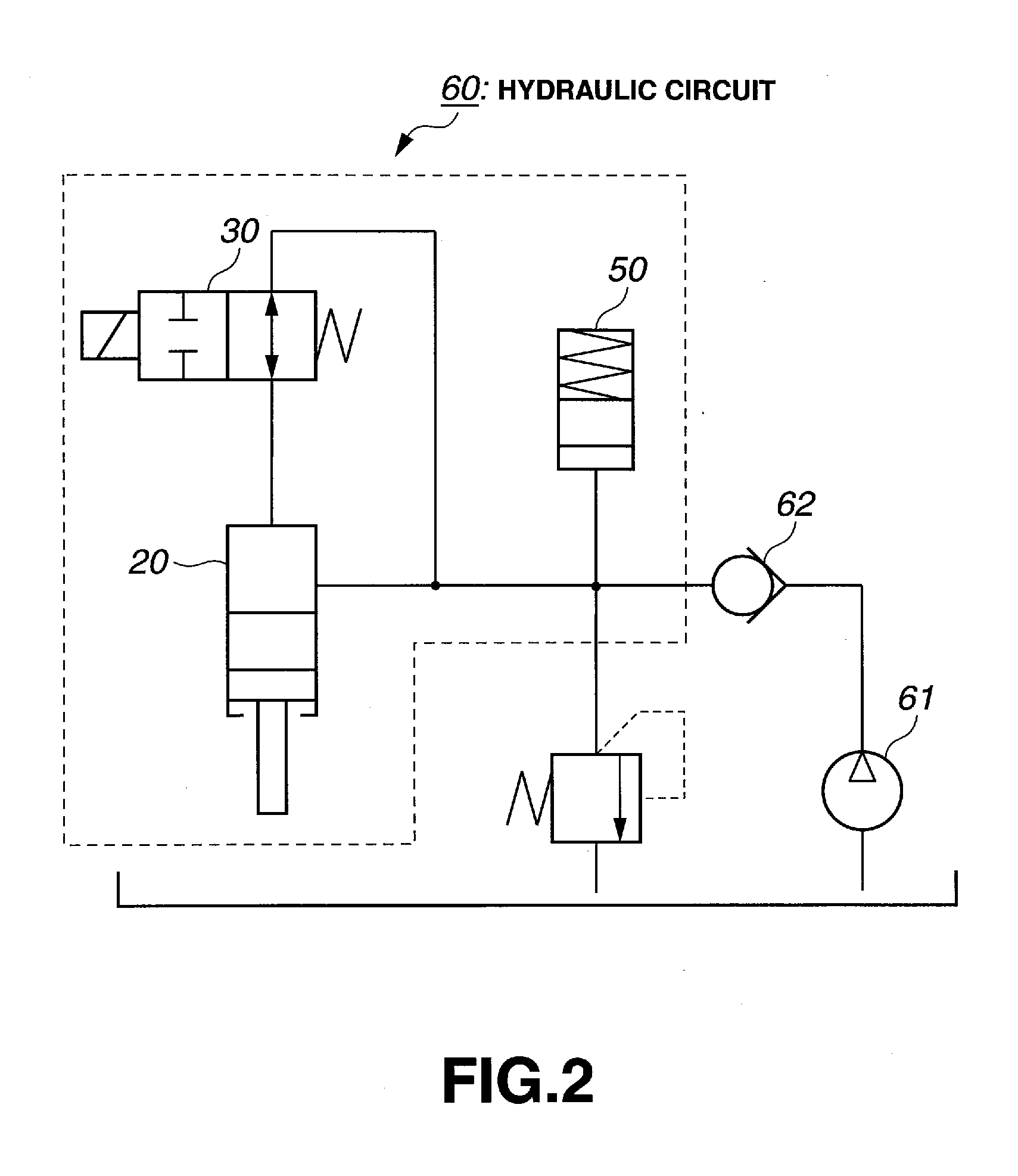

[0040]Referring to FIG. 1, the variable valve device 1 comprises a variable valve device controlling controller (hereinafter simply called “controller”) 90, a gap sensor 24, TDC (Top Dead Center) detection sensor 70, a crank angle detection sensor 72, a hydraulic actuator 20 constituting a hydraulic circuit 60 described later (see FIG. 2), a hydraulic control valve 30, an accumulator 50 and a diesel en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com