Skewed axial fan assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

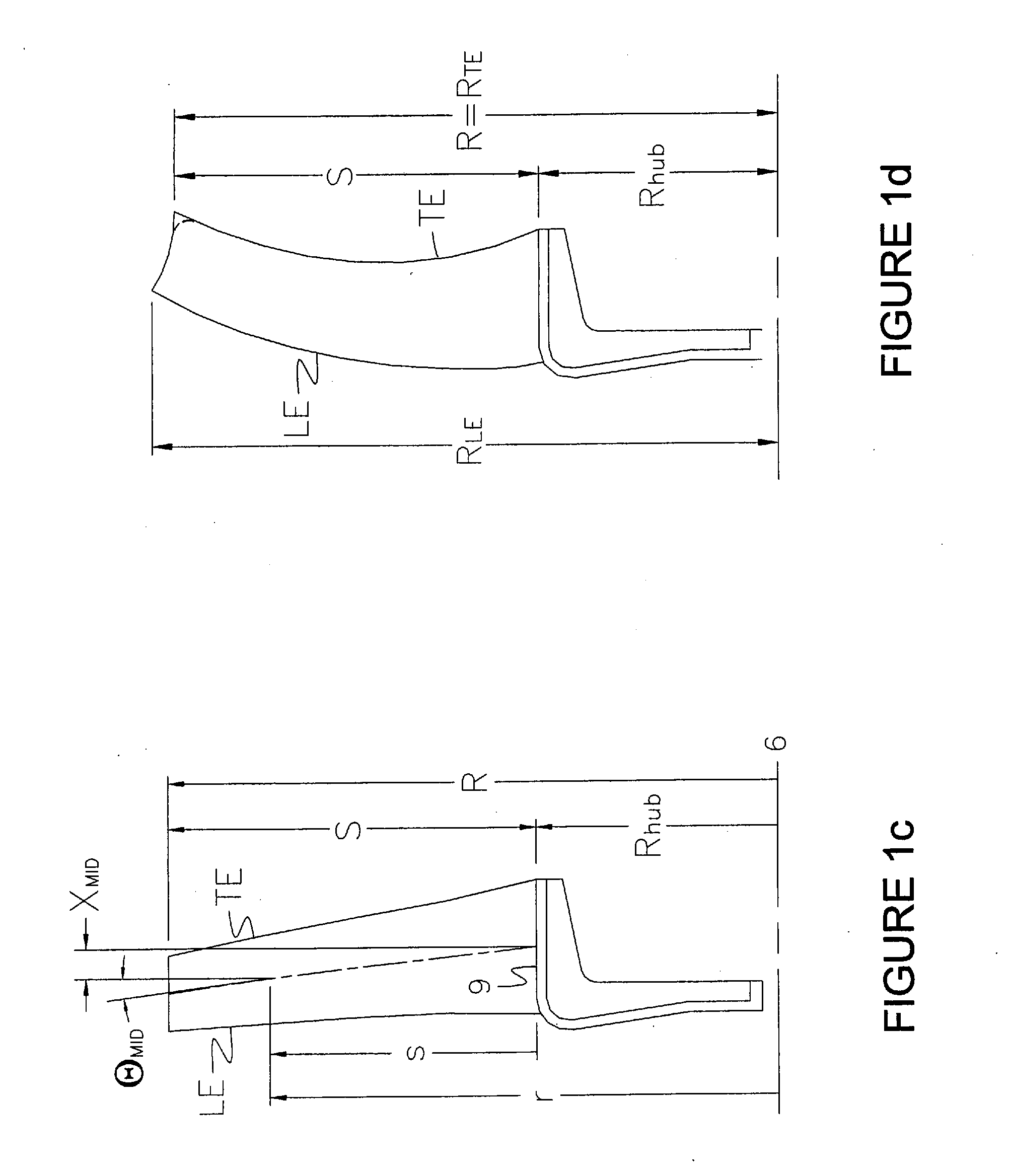

the fan shown in FIG. 2a, with definitions of various geometric parameters.

[0034]FIG. 3a shows an axial projection of a prior-art fan with a blade tip which conforms to a flared shroud and a negative leading-edge sweep angle in a radially outer region.

[0035]FIG. 3b shows an axial projection of one blade of the fan shown in FIG. 3a.

[0036]FIG. 3c is a schematic of the bending forces exerted on the trailing-edge portion of the radially outer region of the blade shown in FIG. 3b.

[0037]FIG. 4a shows an axial projection of a fan according to one construction of the present invention.

[0038]FIG. 4b shows an axial projection of one blade of the fan shown in FIG. 4a.

[0039]FIG. 5a shows an axial projection of a fan according to one construction of the invention.

[0040]FIG. 5b shows an axial projection of one blade of the fan shown in FIG. 5a.

[0041]FIG. 6 shows a plot of calculated radial deflection of the blade tip for the fans shown in FIGS. 3, 4, and 5.

DETAILED DESCRIPTION

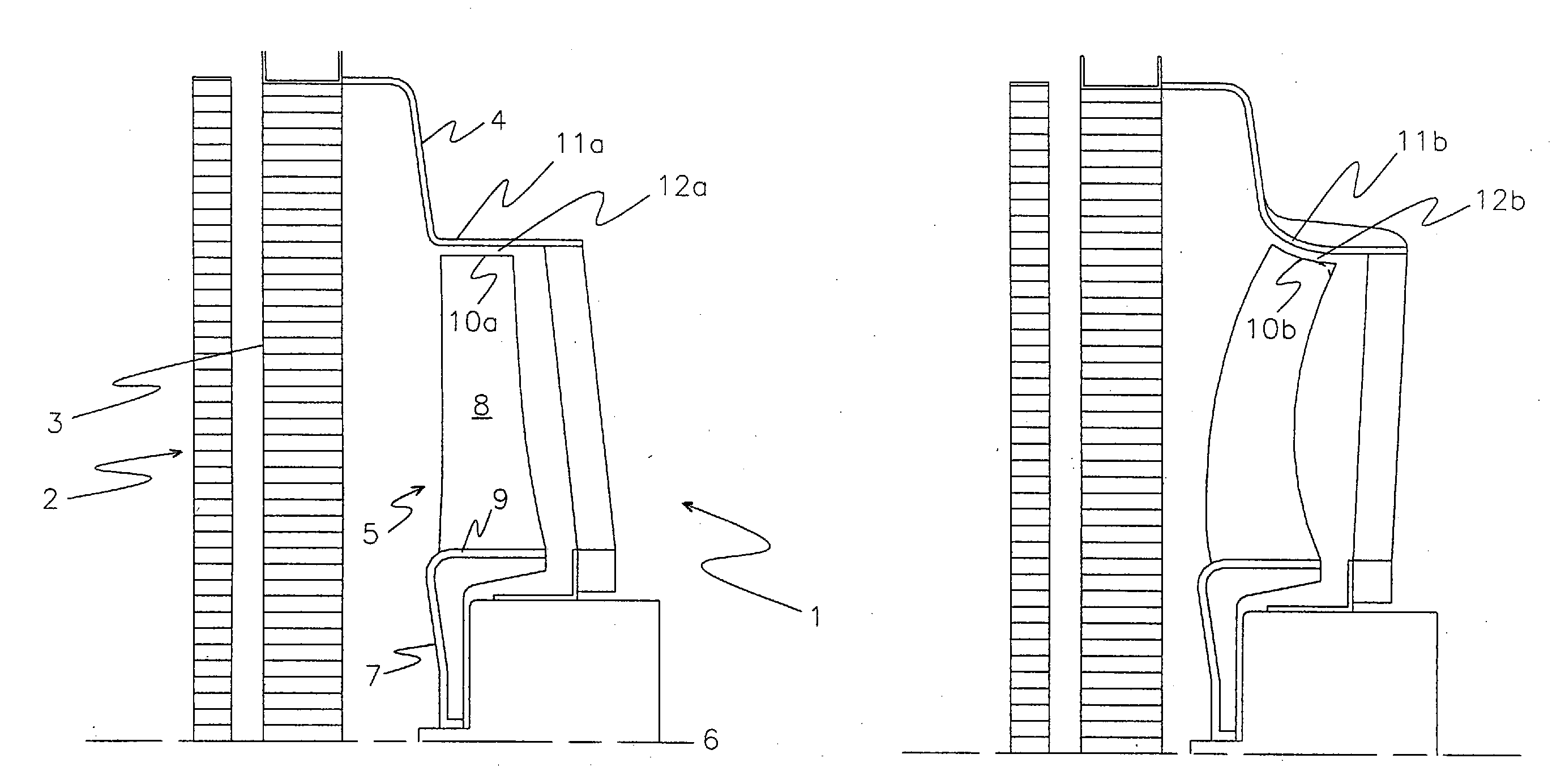

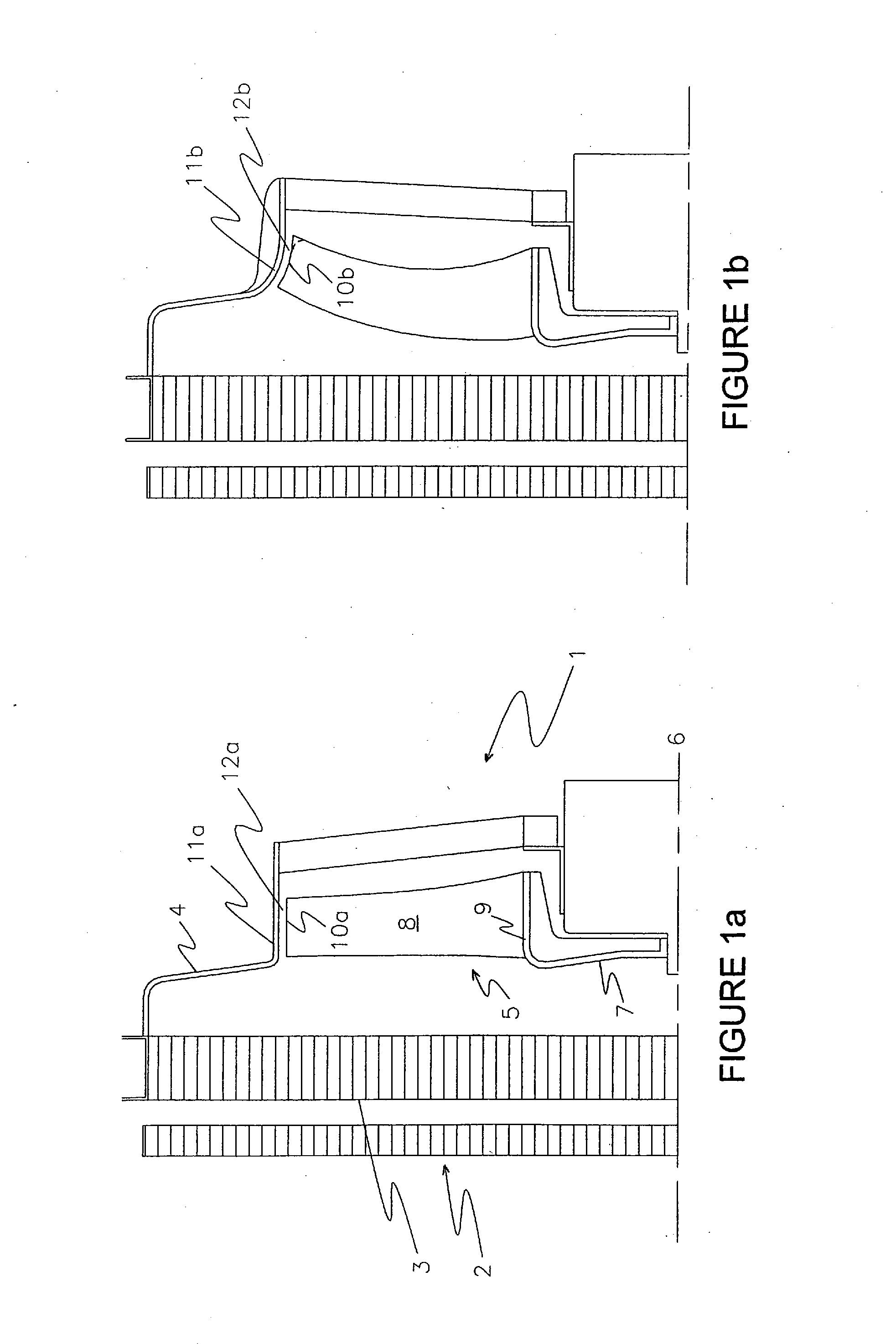

[0042]FIG. 1a sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com