Optical filter and analytical instrument

an optical filter and filter body technology, applied in the field of optical filters and analytical instruments, can solve the problems of diaphragm section breakage and strength degradation, and achieve the effects of reducing the maximum applied voltage, enhancing the strength of the diaphragm section, and preventing the diaphragm section from deteriorating strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Hereinafter, an optical filter according to an embodiment of the invention will be explained. Here, as the optical filter, an optical filter of an air-gap type and of an electrostatic-drive type will be explained.

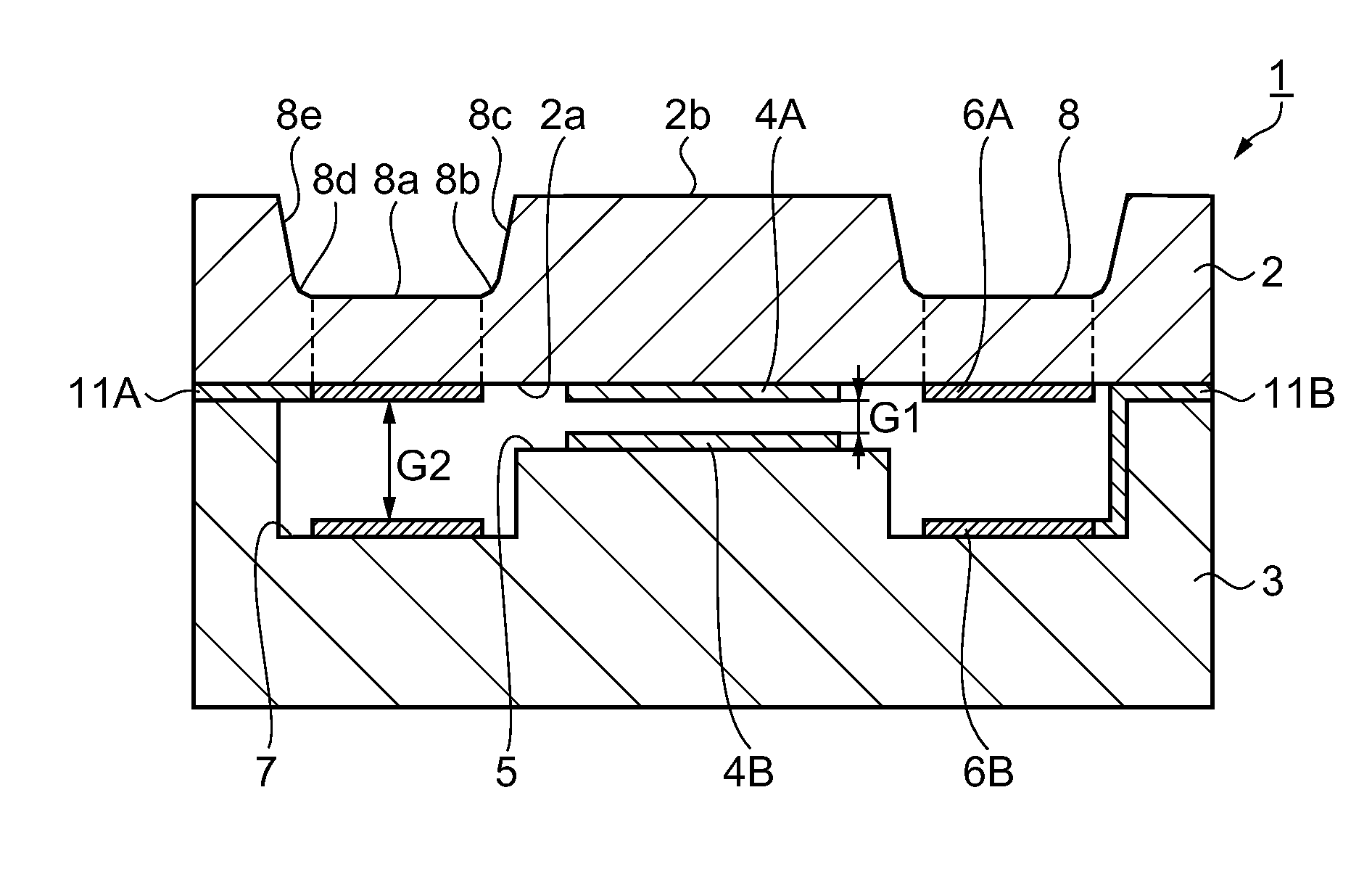

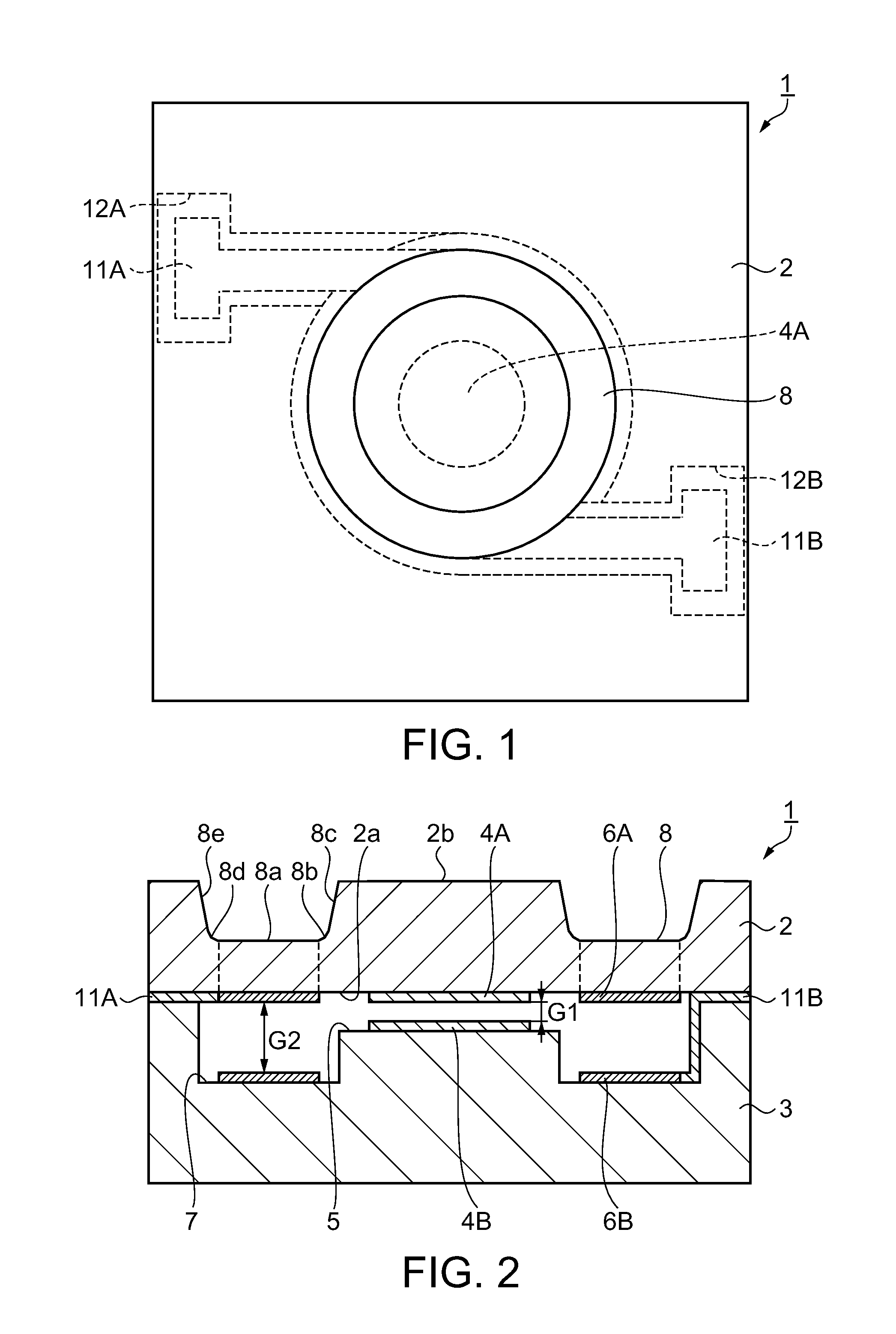

[0030]In FIGS. 1 and 2, the reference numeral 1 denotes an optical filter of the air-gap type and of the electrostatic-drive type. The optical filter 1 is composed of an upper substrate 2, a lower substrate 3 bonded (or joined with an adhesive) to the upper substrate 2 in the state of being opposed thereto, a mirror 4A (an upper mirror) having a circular shape disposed at a central portion of an opposed surface 2a of the upper substrate 2, the opposed surface 2a being opposed to the lower substrate 3, a mirror 4B (a lower mirror) having a circular shape disposed at a central portion of a bottom surface of a first recessed section 5 formed at a central portion of a surface of the lower substrate 3, the surface being opposed to the upper substrate 2, so as to be opposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com