Pulsed magnetic actuation for sensitive assays

a magnetic actuator and sensitive technology, applied in the field of magnetic field control, can solve the problems of signal loss, decreased sensitivity of assay, and very laborious and time-consuming methods, and achieve the effect of reducing sensitivity and avoiding surface damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

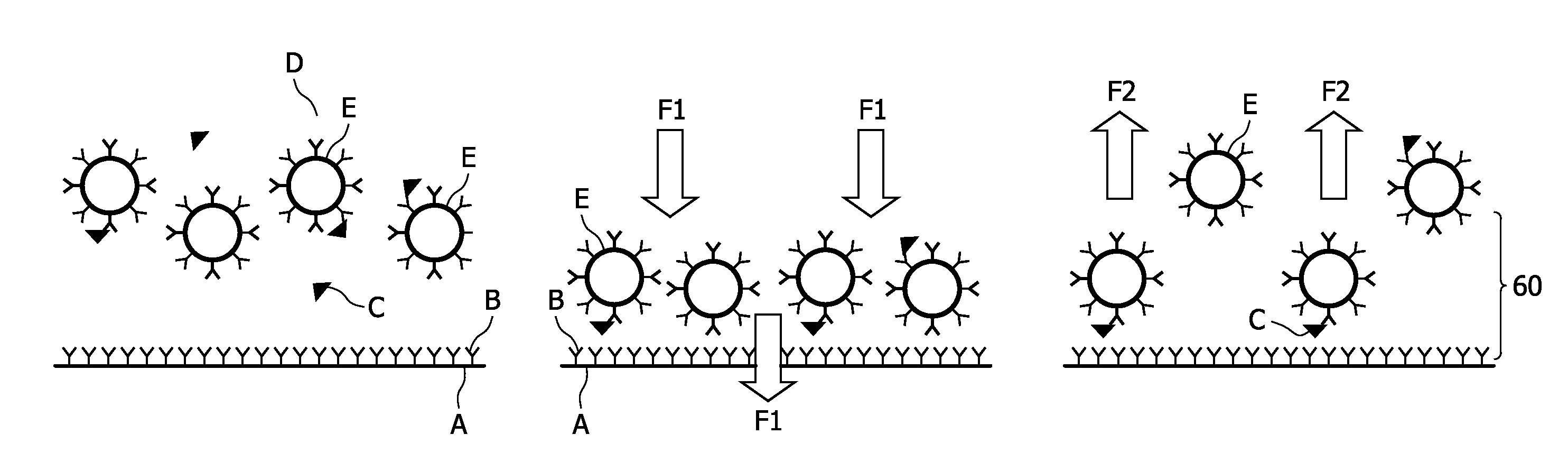

[0059]The inventors of the present invention identified the presence of lateral forces (parallel to the sensor surface), acting on particles that are close to the sensor surface as one of the main contributors of the above described problem. Compared to forces perpendicular to the sensor surface, these lateral forces can probably induce much higher forces on the biological bonds through the large torque that is created.

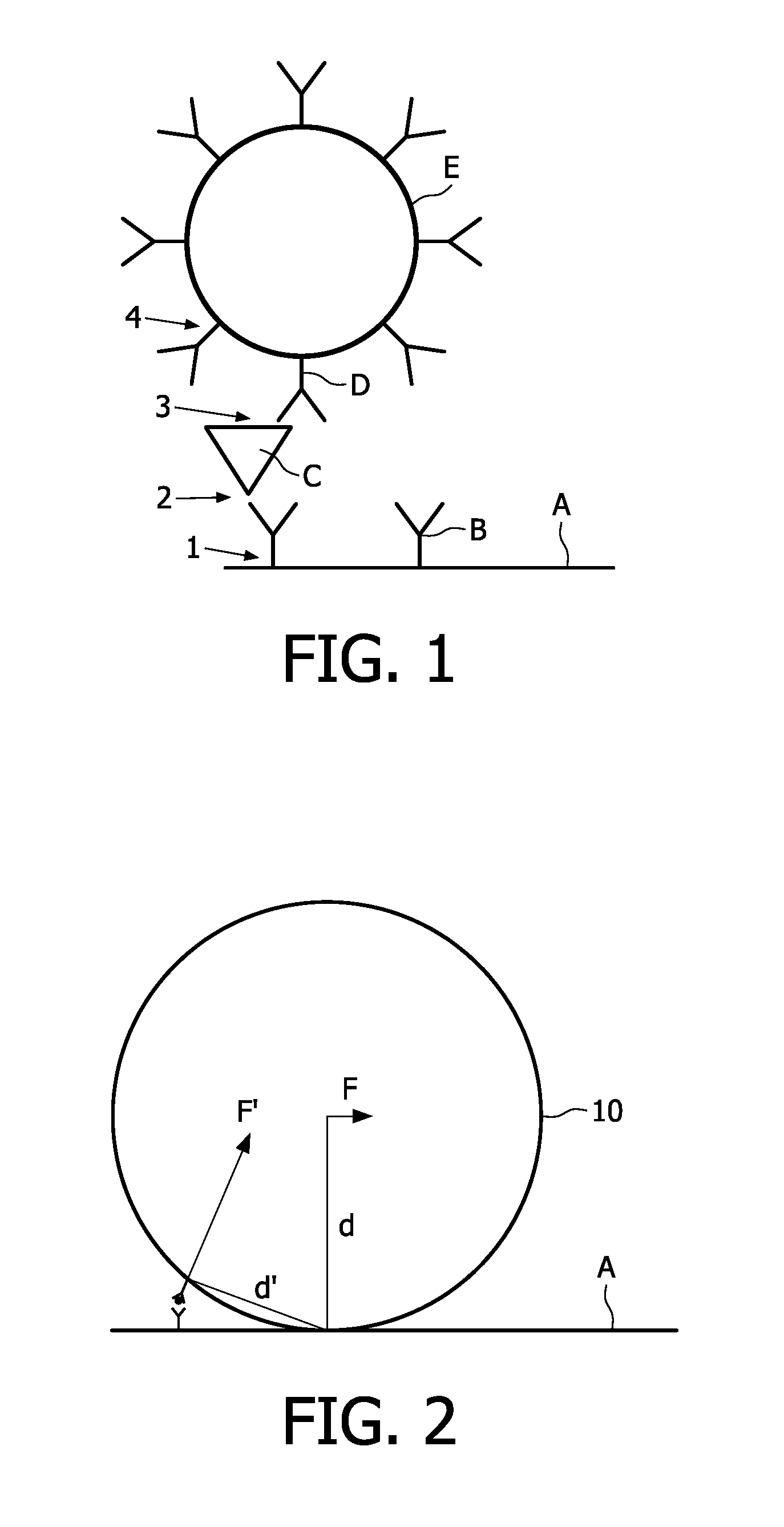

[0060]In particular, FIG. 2 illustrates how a relatively small force F, parallel (lateral) to the sensor surface, can induce a relatively larger force on a biological bond due to the long arm “d” created by the relatively large size of the magnetic particle 10. The resulting force, which acts on the bond between the particle and the bond is indicated by F′ which is significantly larger than the parallel force F. Moreover, the inventors of the present invention also observed that single unbound particles can be dragged over the sensor surface and remove already bound p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap