Electric outboard motor

a technology of electric motors and outboard motors, applied in the direction of propulsive elements, marine propulsion, vessel construction, etc., can solve the problems of adversely affecting the electric motor, complicated structure, and heat generation, and achieve the effect of improving the cooling efficiency of the electric motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

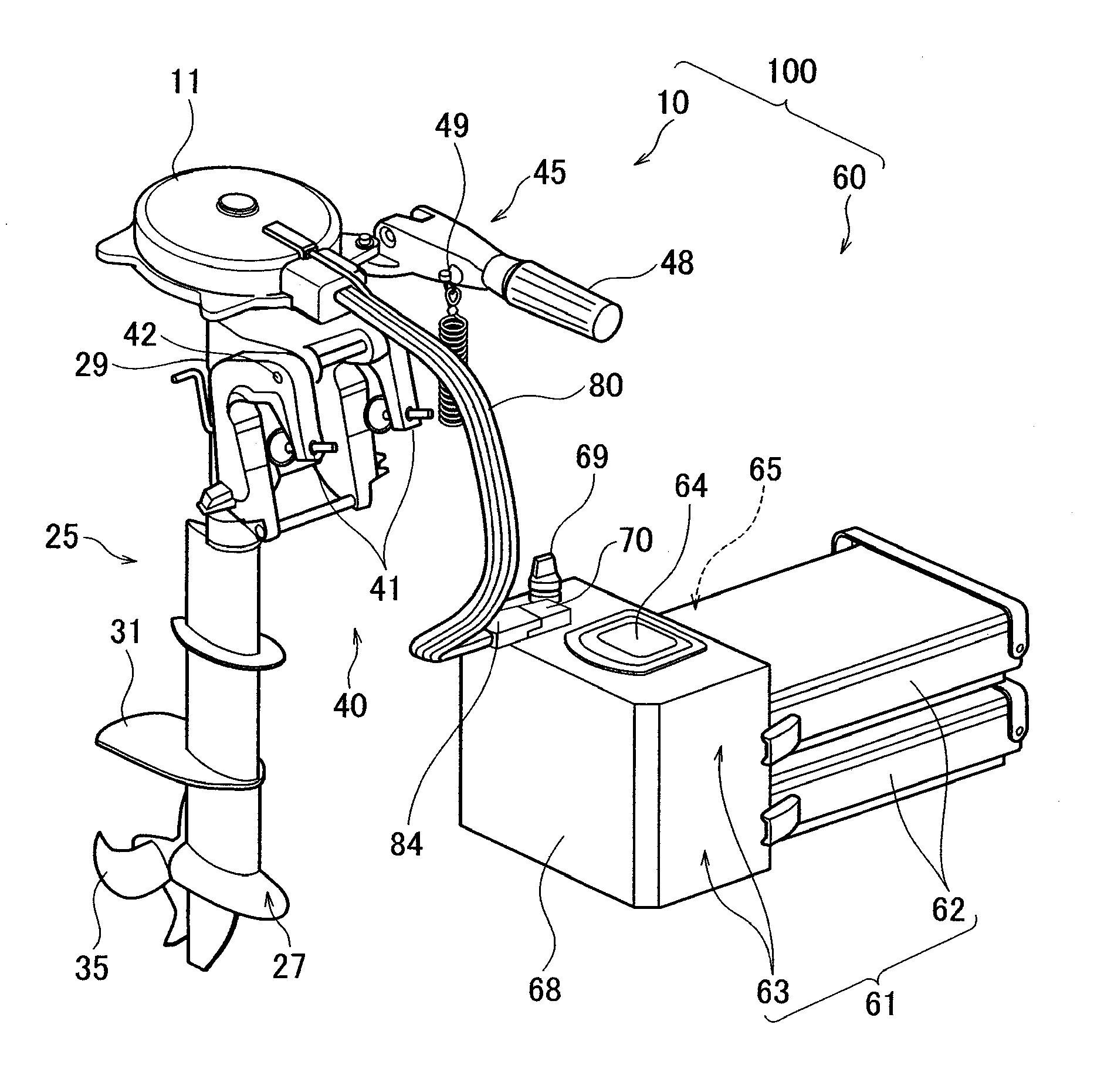

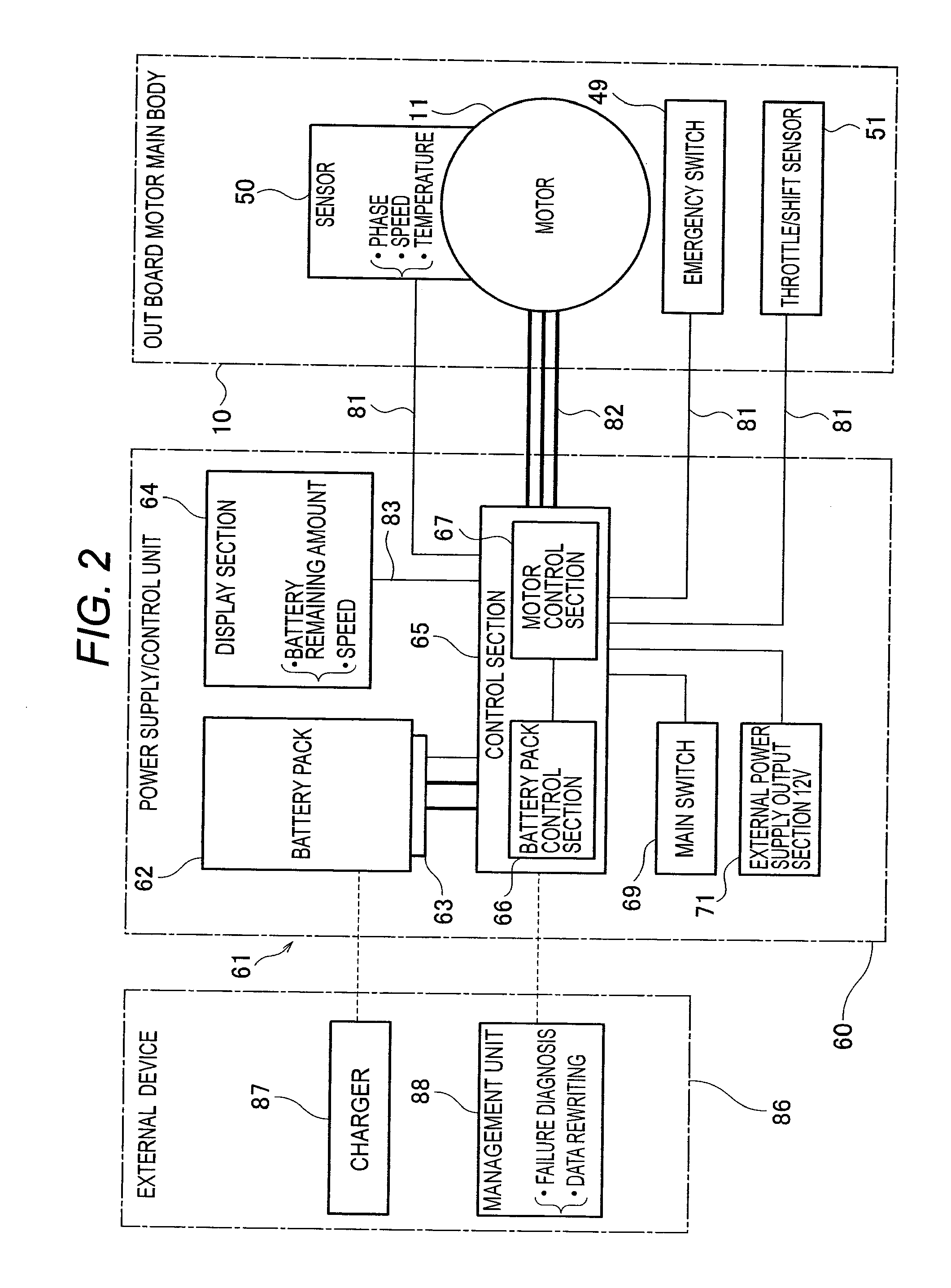

[0040]The entire structure of an electric outboard motor 100 according to an embodiment will be explained with reference to FIG. 1 and FIG. 2. FIG. 1 is an appearance view of the electric outboard motor according to this embodiment, and FIG. 2 is a view showing an electric outboard motor system including the electric outboard motor.

[0041]As shown in FIG. 1, the electric outboard motor 100 is provided with an electric outboard motor main body 10 and a power supply / control unit 60, and the both are formed separately. Further, the electric outboard motor main body 10 and the power supply / control unit 60 are electrically connected by a cable 80. The electric outboard motor main body 10 and the power supply / control unit 60 are formed separately, thereby separating the power supply / control unit 60 from the electric outboard motor main body 10 to enable the power supply / control unit 60 to be disposed at a position where a barycenter balance in a hull is stabilized, resulting that it is pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com