Semiconductor device having a hetero-junction bipolar transistor and manufacturing method thereof

a semiconductor device and heterojunction technology, applied in the field of hbt and hfet integrated circuits, can solve the problems of bipolar transistor character deterioration, semiconductor device becoming more prone to breakdown, and current amplification factor (hfe) to decrease, so as to reduce collector resistance, prevent the effect of collector breakdown voltage decrease, and superior high frequency characteristics and processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

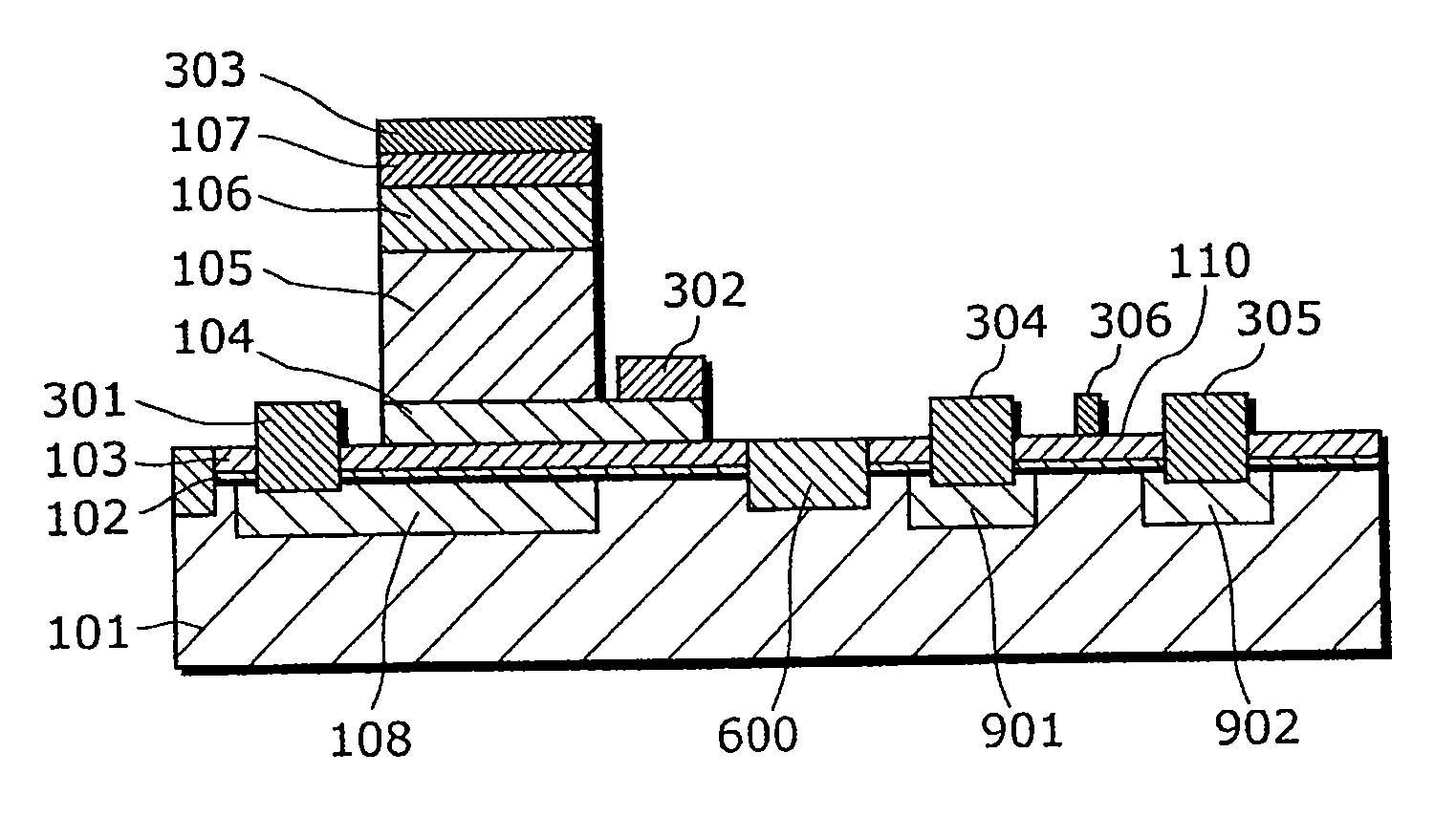

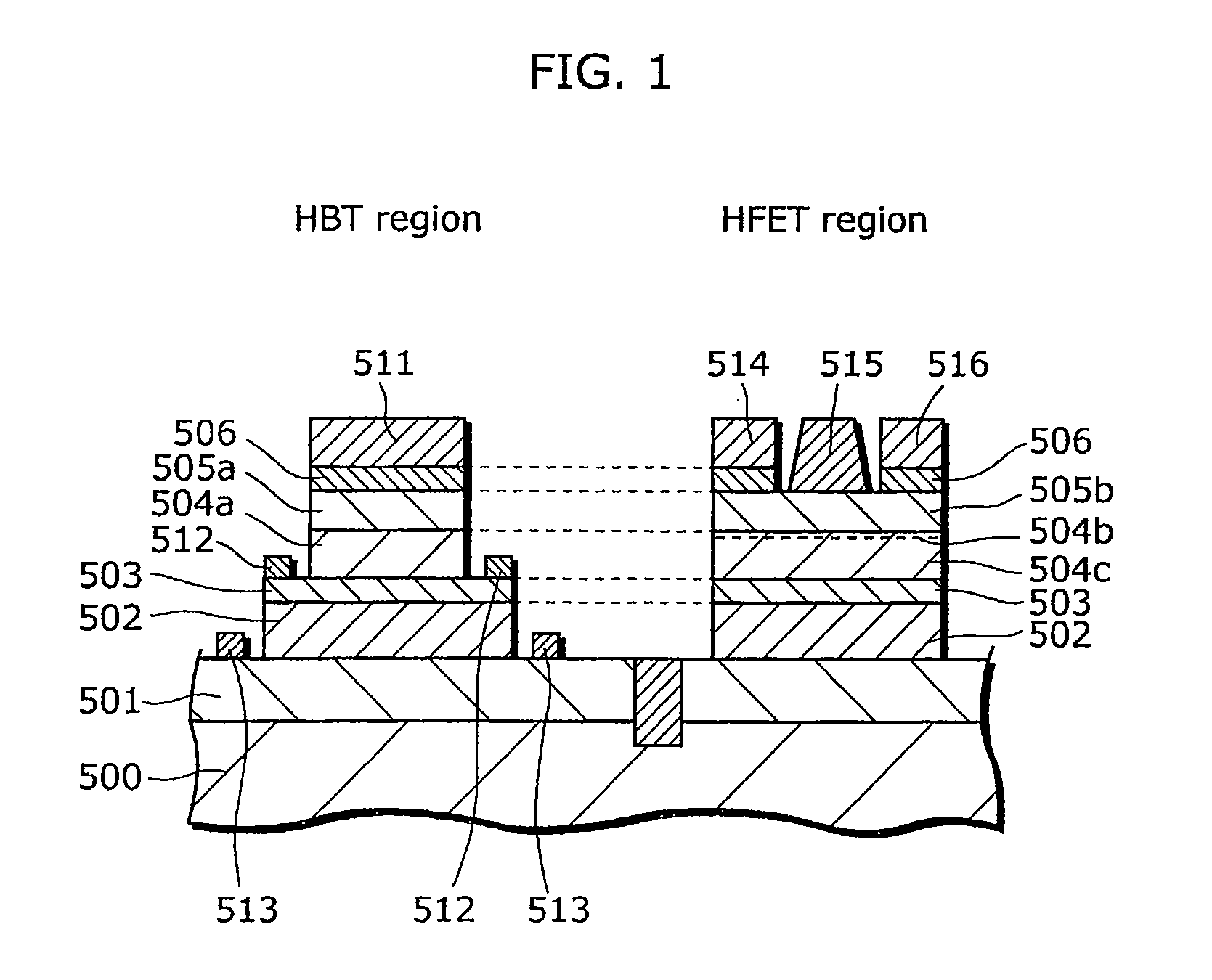

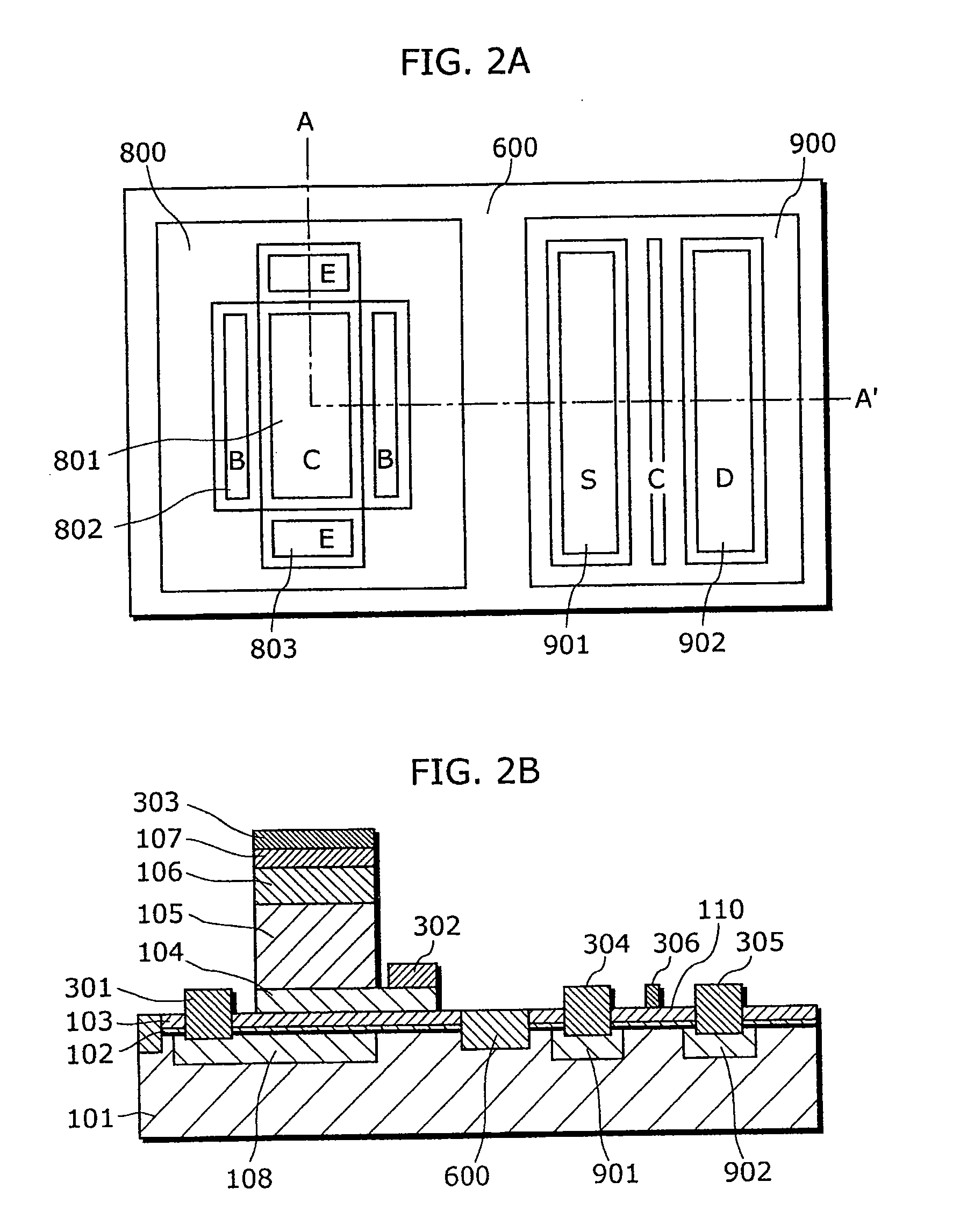

[0053]FIG. 2A is an overhead diagram which shows the structure of the HBT and HFET integrated circuit according to the first embodiment of the present invention. FIG. 2B is a cross section diagram which shows the structure of the same integrated circuit (the cross section diagram along the line A-A′ in FIG. 2A).

[0054]The integrated circuit includes a region (HBT region) 800 which functions as a collector-up type HBT, and a region (HFET region) 900 which functions as an HFET.

[0055]A channel layer 102 of a first conductivity, an emitter layer 103 of the first conductivity, a base layer 104 of a second conductivity with a band gap smaller than that of the emitter layer 103, a low impurity concentration collector layer 105 or a non-doped collector layer 105 which is of the first conductivity, a sub-collector layer 106 which is of the first conductivity and is doped with a impurity concentration higher than that of the collector layer 105, and a collector cap layer 107 on which a collect...

second embodiment

[0085]Next, a method for manufacturing the HBT and HFET integrated circuit according to the second embodiment of the present invention is described in detail using FIG. 4. FIG. 4 is a cross-section diagram for describing sequential steps of the method for manufacturing the integrated circuit.

[0086]First, the channel layer 102 made of InGaAs, in which an n-type uniformly doped layer or a δ doped layer is formed, is formed on the semi-insulating GaAs substrate 101 by epitaxial growth (FIG. 4(a) and (b)).

[0087]Next, an ion species which functions as an n-type carrier such as an Se ion, is implanted in a predetermined region of the semi-insulating GaAs substrate 101 on which the emitter contact region 108, the source region 901, and the drain region 902 are to be formed on the semi-insulating GaAs substrate 101. For example, the ion species is implanted at an acceleration voltage of 30 keV and with a dose amount of 1×1014cm−3.

[0088]Next, the region in which the ion species has been impl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com