Piston for an internal combustion engine

a technology for internal combustion engines and pistons, which is applied to engines, mechanical equipment, machines/engines, etc., can solve the problems of too much air to be mixed with oil, the oil level in the oil duct in the piston becomes too small, and the structure demonstrates the defect of achieving a continuous oil fill level of the cooling duct, so as to improve the cooling efficiency and control the oil flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

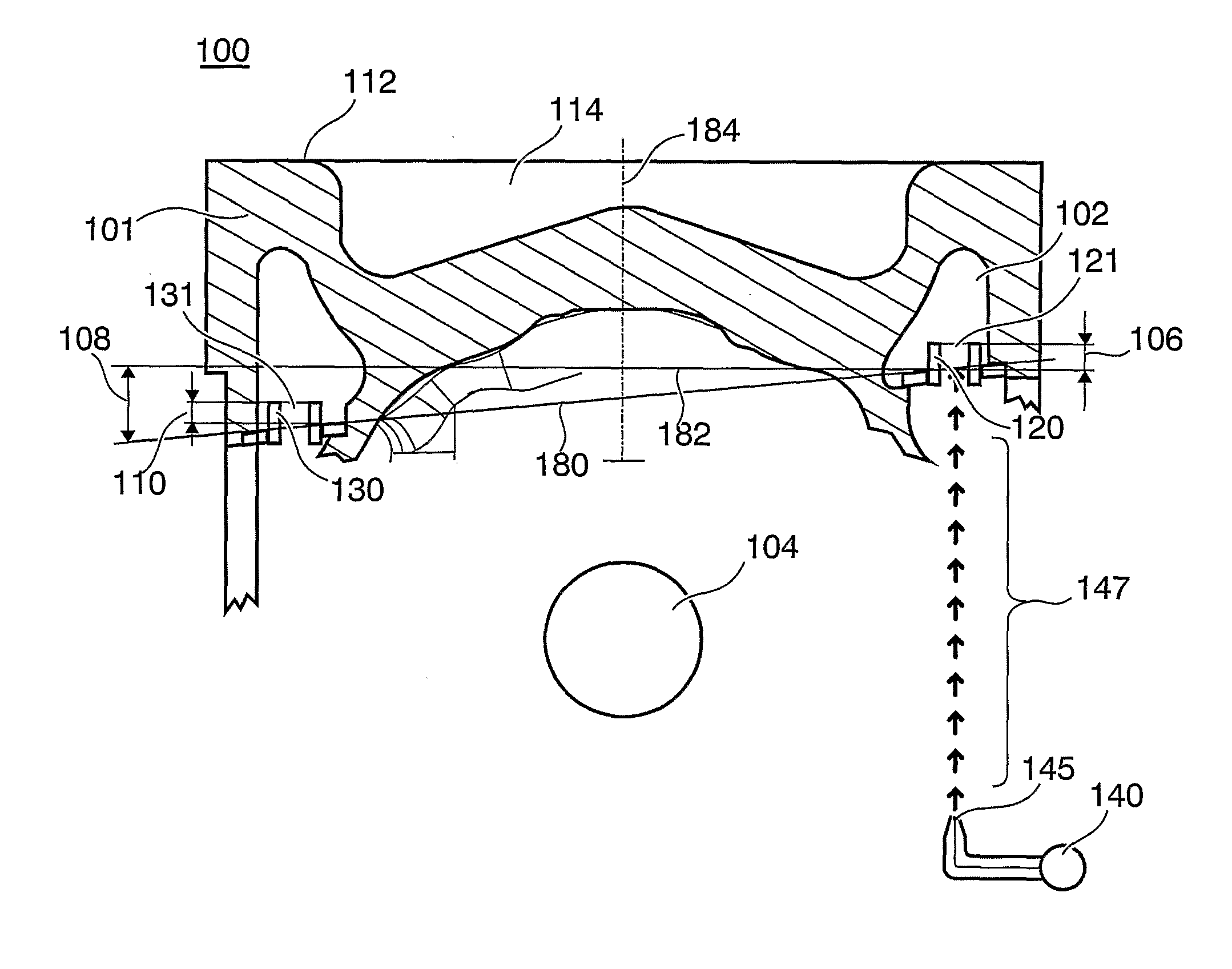

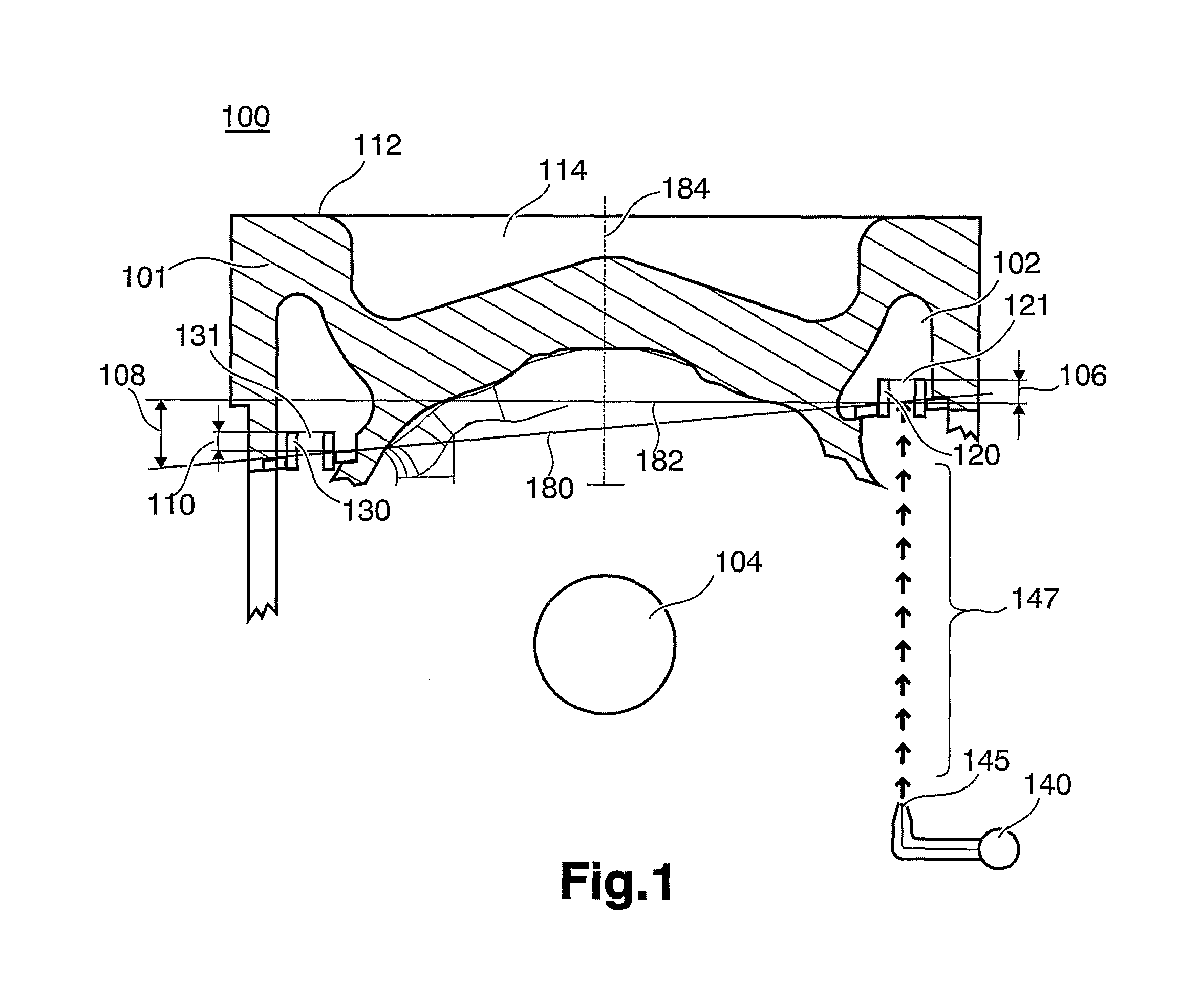

[0020]FIG. 1 depicts schematically a cross sectional view of an example embodiment according to the present invention of a cooling structure for an internal combustion engine piston 100. Said piston 100 comprising a body 101, a top surface 112, a combustion chamber cavity 114, an oil cooling channel 102, a wrist pin opening 104, an oil inlet 121, an oil inlet mechanical stop 120, an oil outlet 131, and an oil outlet mechanical stop 130.

[0021]Oil is provided to the oil cooling channel 102 in said piston by a nozzle 145 attached to an oil pump 140. The oil is injected into the oil inlet 121 in the piston from below as indicated by arrows 147 in FIG. 1. The oil pump 140 may be the same pump as used to circulate oil to the engine bearings. A separate pump 140 may also be used for injecting oil to the pistons.

[0022]The combustion chamber cavity is typical for self igniting engines such as diesel engines. However, a top portion in natural aspirated gasoline engines may very well have the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com