Electronic blast control system for multiple downhole operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

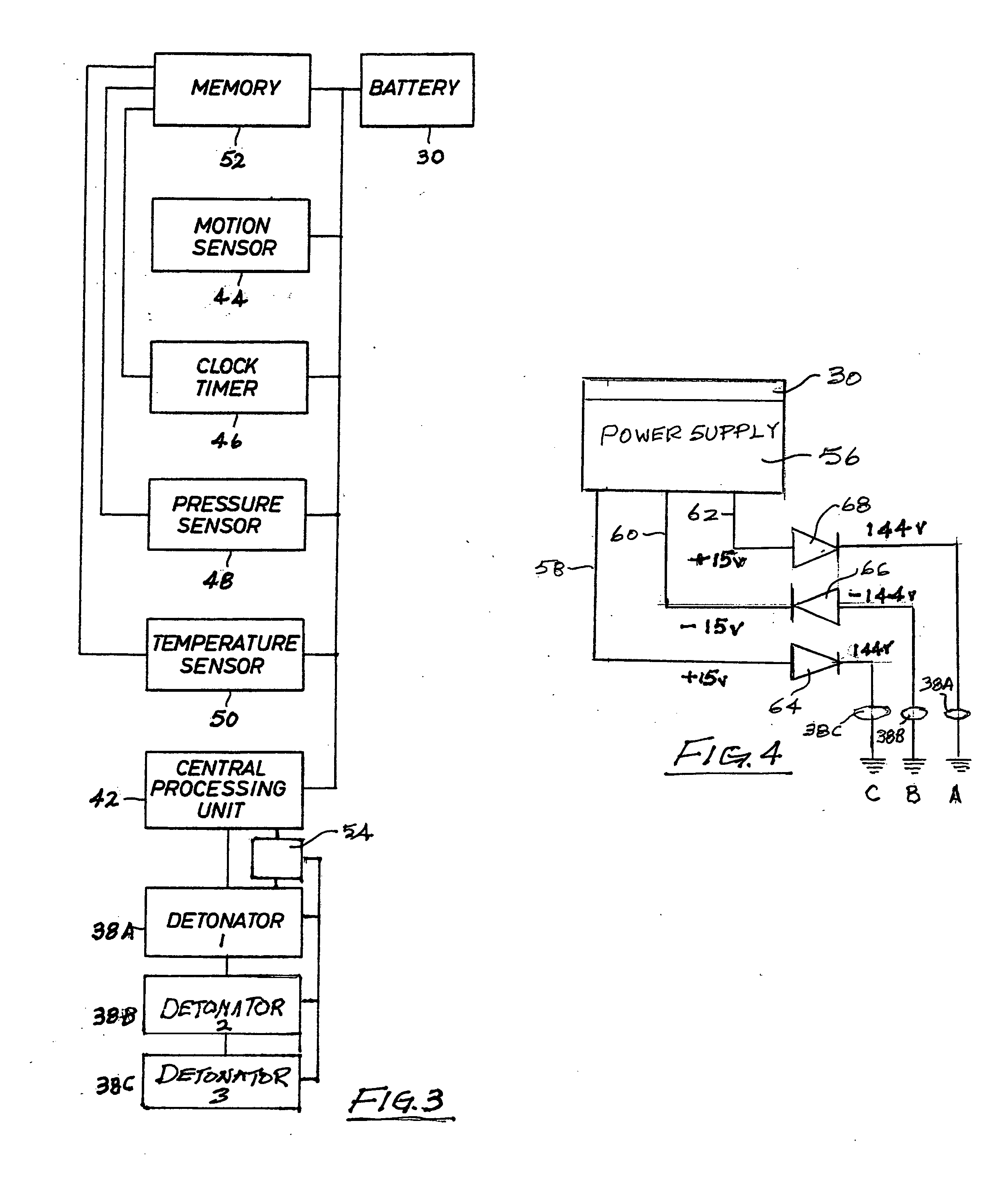

[0023]The term “blast control” as used herein is intended to mean a control system for two or more electronically initiated and sequentially activated devices that develop an explosive force or rapid generation of combustion gas in the downhole environment for the purpose of doing desired work. The work may take the form of casing perforation by sequential or series explosive shaped charges that develop specifically oriented hot gas jets for perforation of well casing or make take the form of packers, anchors and the like which are activated to set positions by explosive generation of gas.

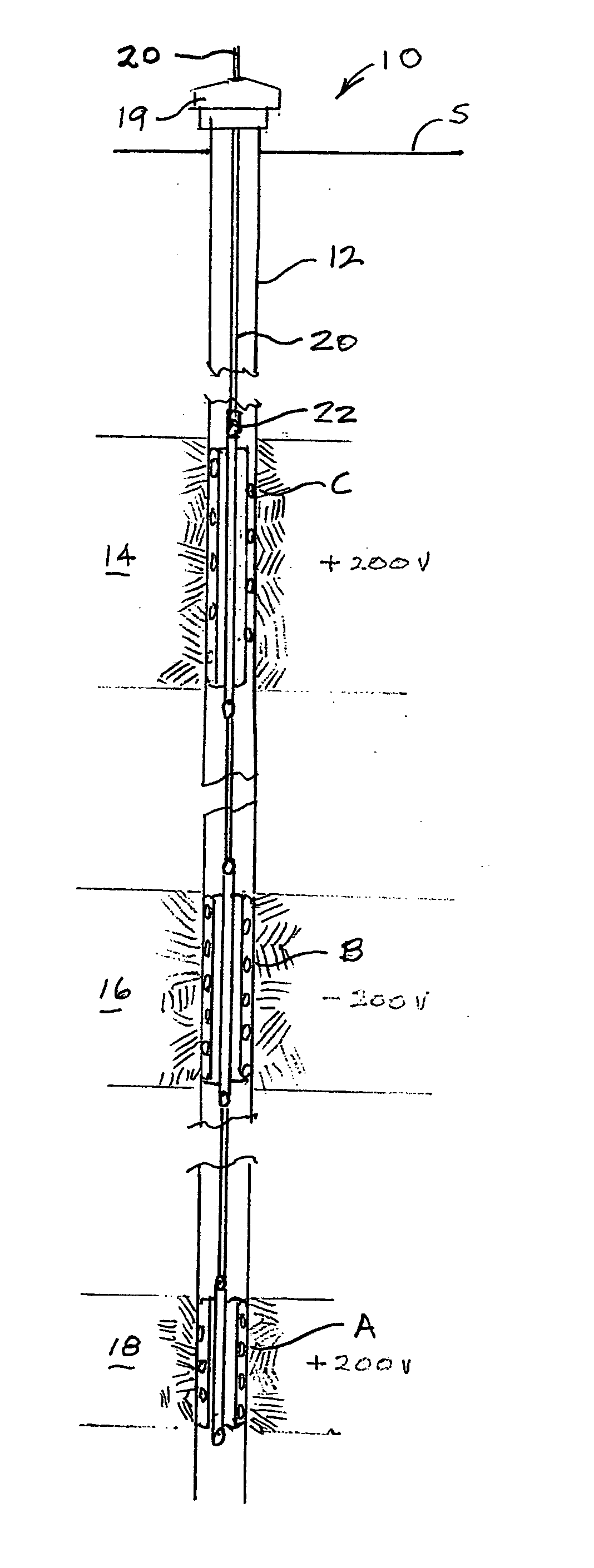

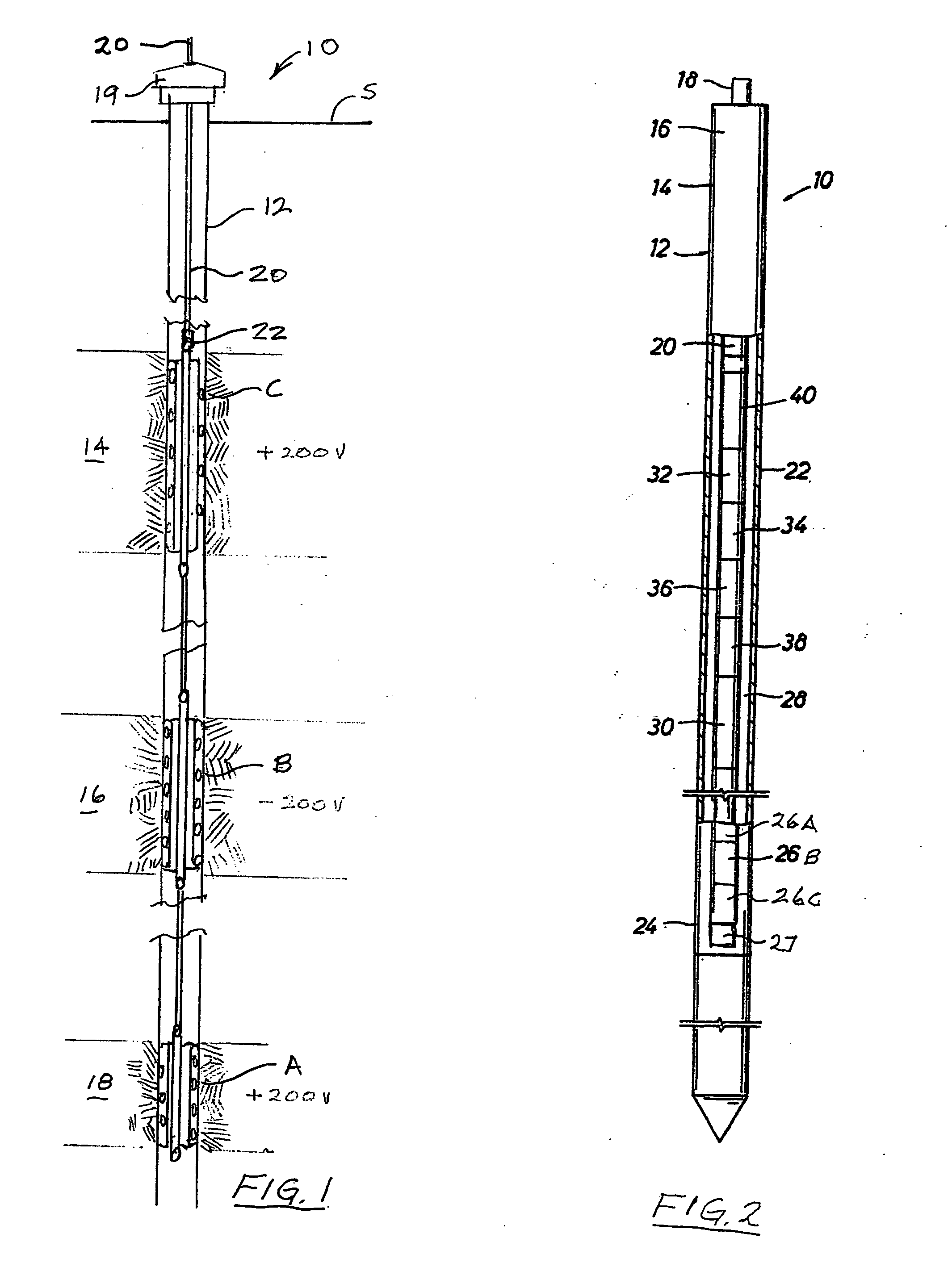

[0024]Referring now to the drawings and first to FIG. 1, a well for production of petroleum products such as crude oil and natural gas is shown generally at 10 and incorporates a well casing 12 that lines a borehole intersecting a plurality of subsurface production formations 14, 16 and 18. The well casing is connected with a wellhead 19 which extends above the surface “S”. Though not shown, a wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com