Methods and apparatus for acoustic treatment of samples for heating and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

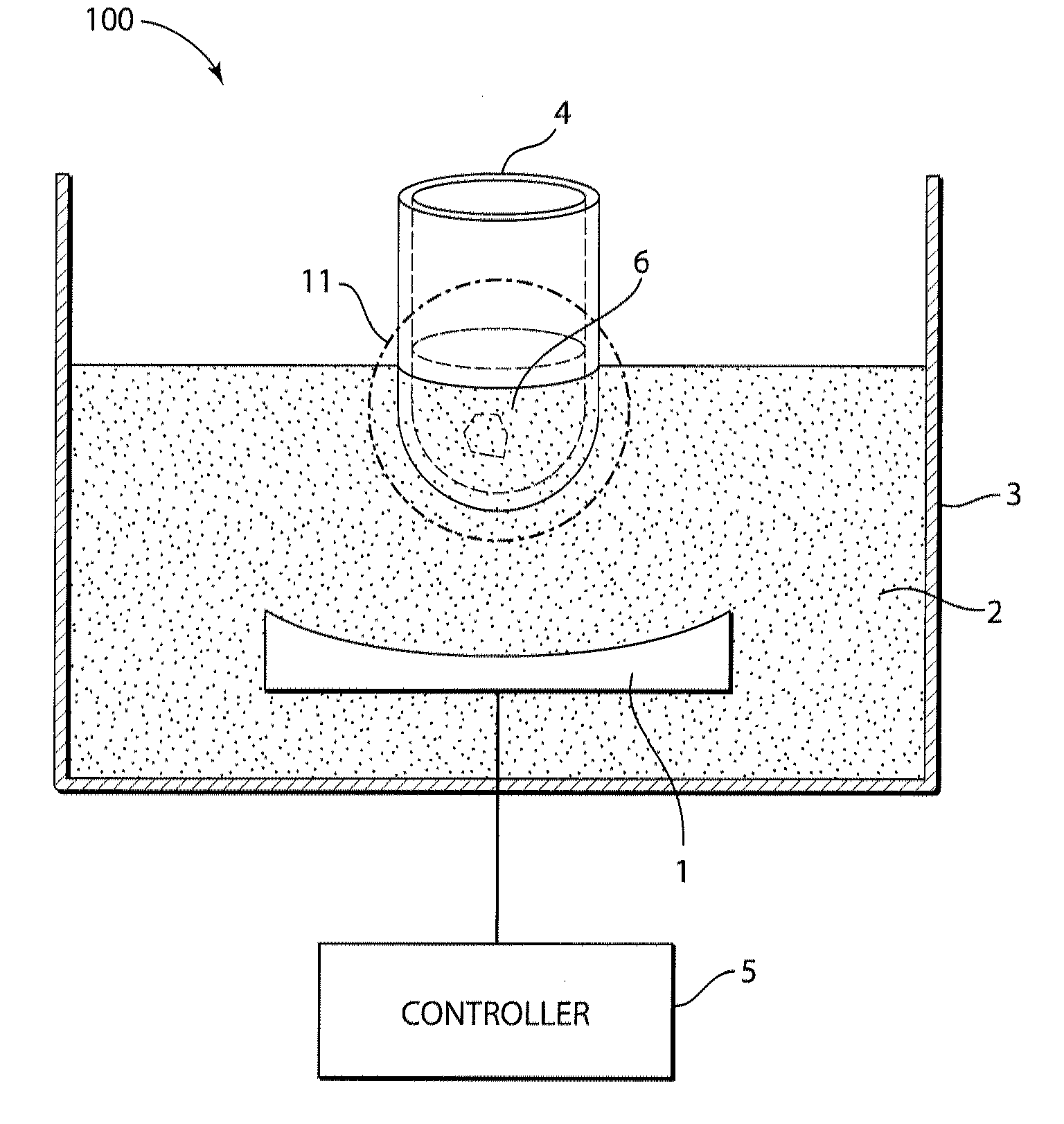

Image

Examples

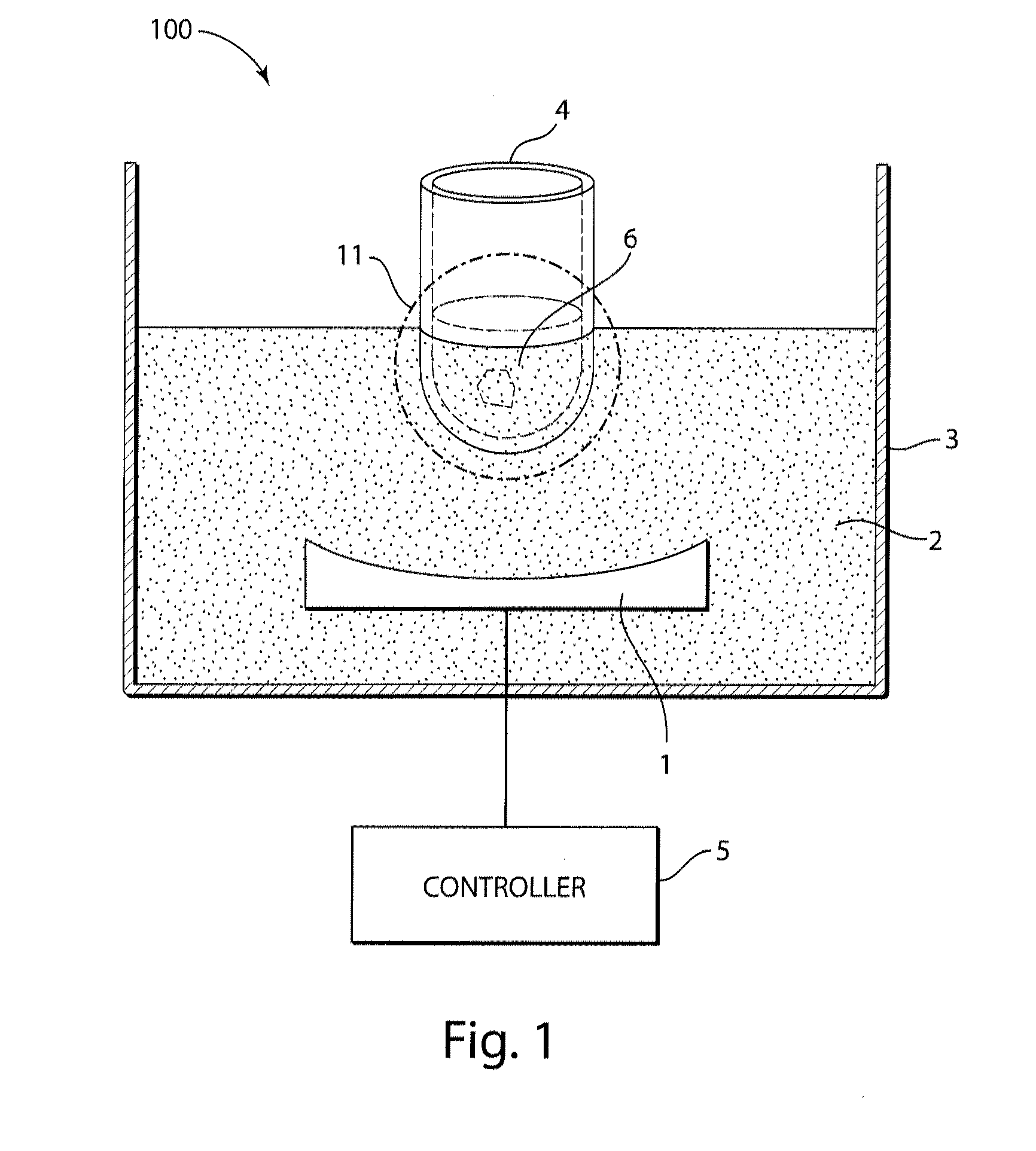

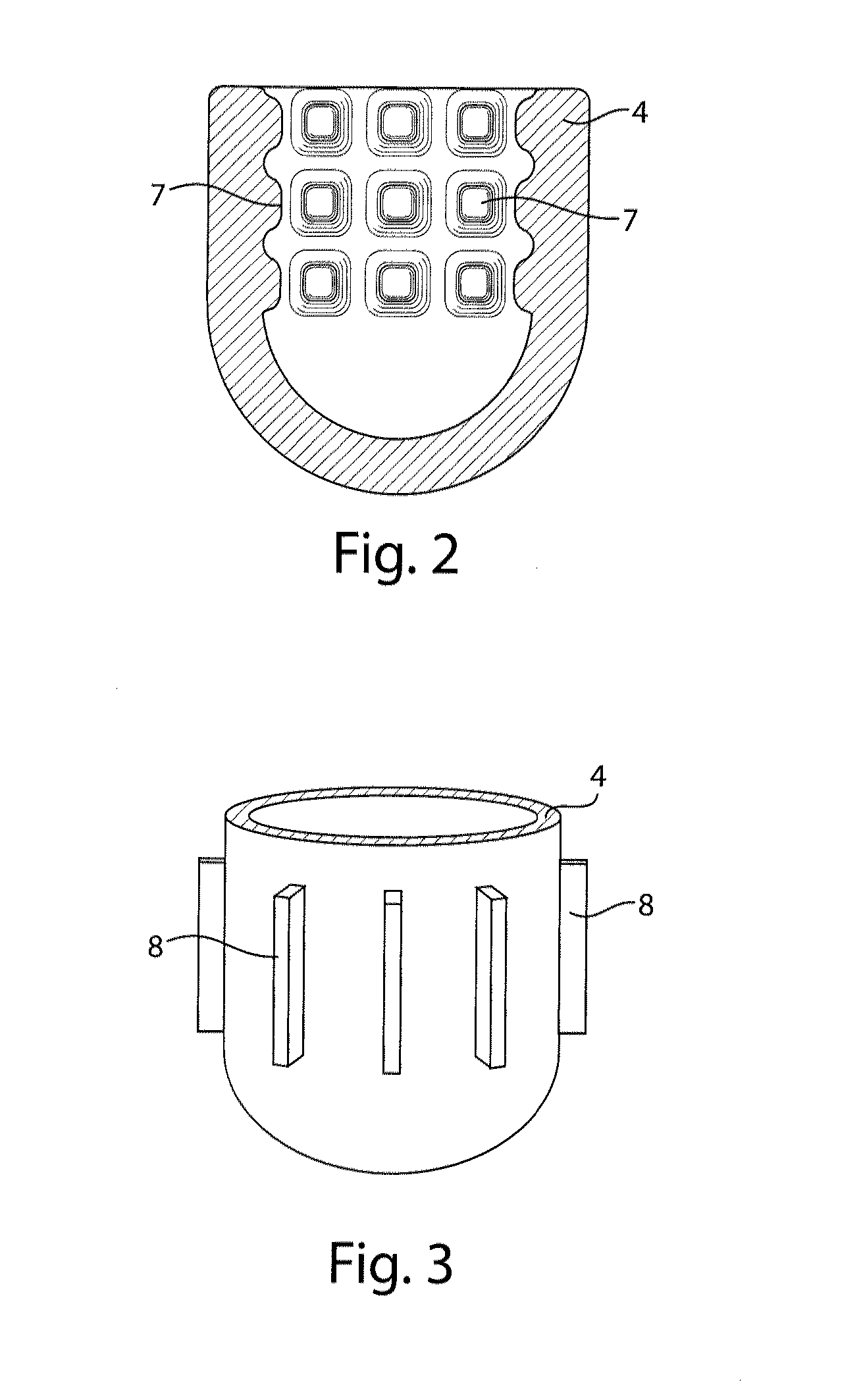

Embodiment Construction

[0019]Although aspects of the invention are described with reference to embodiments in which acoustic energy is used to heat and / or cool a sample, the sample may be subjected to other treatments or other processes by the acoustic energy. For example, the acoustic energy may also be suitable, or be adjusted, to cause other effects in the liquid, such as fluidizing the sample, mixing the sample, stirring the sample, catalyzing the sample, disrupting the sample (such as shearing or fragmenting DNA molecules or other compounds, lysing cells, etc.), permeabilizing a component of the sample, enhancing a reaction in the sample (such as binding of material to the material supports), causing crystal growth in the sample (e.g., by nucleating crystal growth sites and / or enhancing the rate of crystal growth), preparing formulations (e.g., suspensions and / or emulsions suitable for therapeutic use), causing flow in a conduit, and / or sterilizing the sample. Thus, the acoustic energy may be used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com