Water-resistant plywood substitutes made from recycled carpets or textiles

a technology of recycled carpets and plywood, applied in the field of solid materials handling, can solve the problems of large amount of energy required in the manufacture process, non-uniform heating, and inability to meet the needs of customers, and achieve the effects of high water resistance, high resistance to cracking or splitting, and good water resistance substitutes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

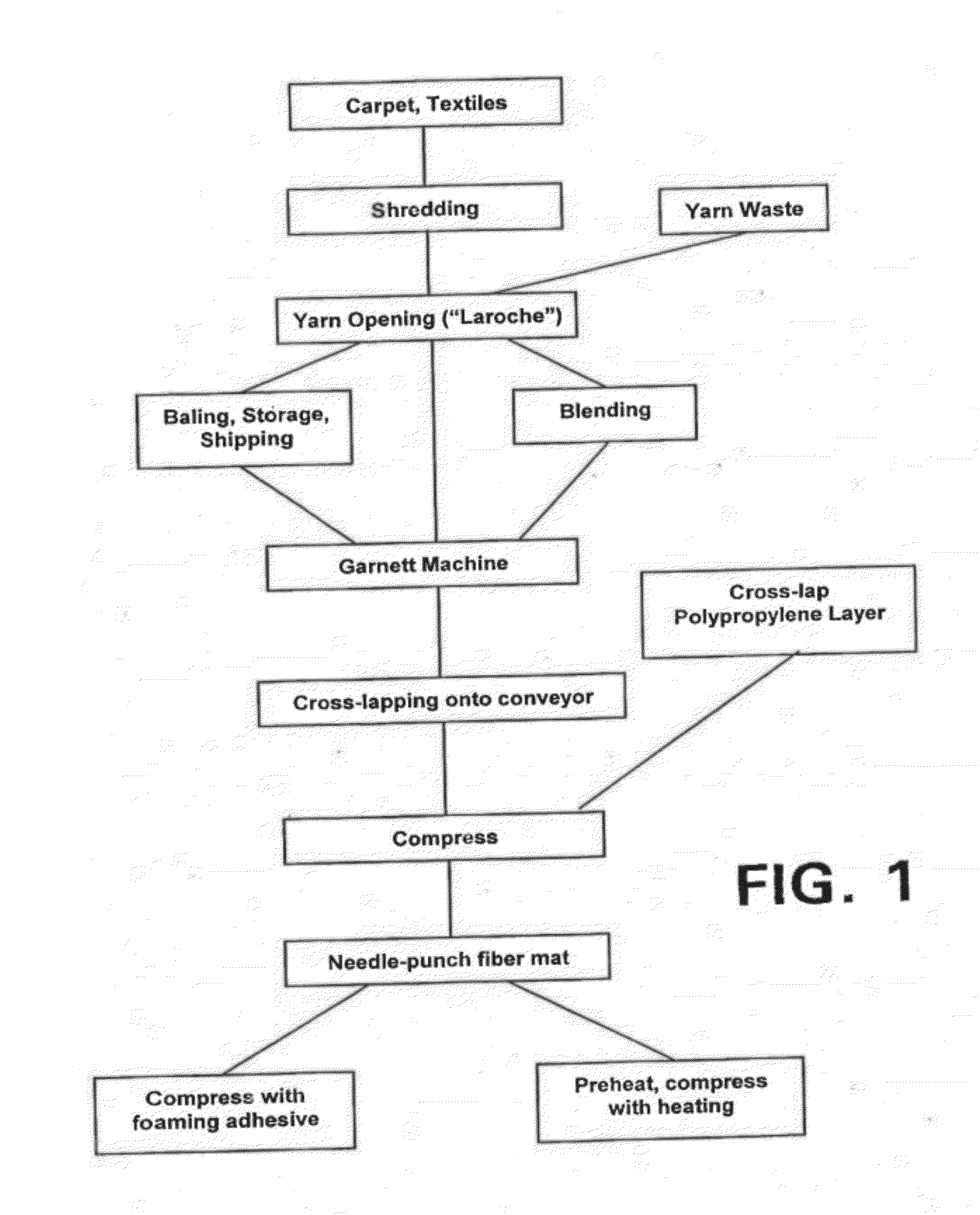

[0049]This invention relates to a method of using shredded material from discarded carpet segments (or possibly other recycled textile waste) to make wood-like materials, in large formed “sheets” that are comparable to sheets of plywood, particle board, “chip board”, etc.

[0050]As used herein, terms such as “discarded” and “recycled” are used interchangeably. These terms refer to any type of fibrous material that is used as a feedstock in a manufacturing operation as described herein. Such materials include rolls or segments of carpet, as well as bales, piles, or any other aggregations of fabrics, textiles, or other fibrous materials. Such recycled material may be or include post-consumer material that has been discarded in a used and worn condition; alternately, it may be or include never-used material, such as material discarded because of imperfections, because it didn't sell, because it became tailing or side-trim scrap, or for any other reason.

[0051]The terms “wood-like material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| widths | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com