MODULAR REFRIGERATOR and ICEMAKER

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

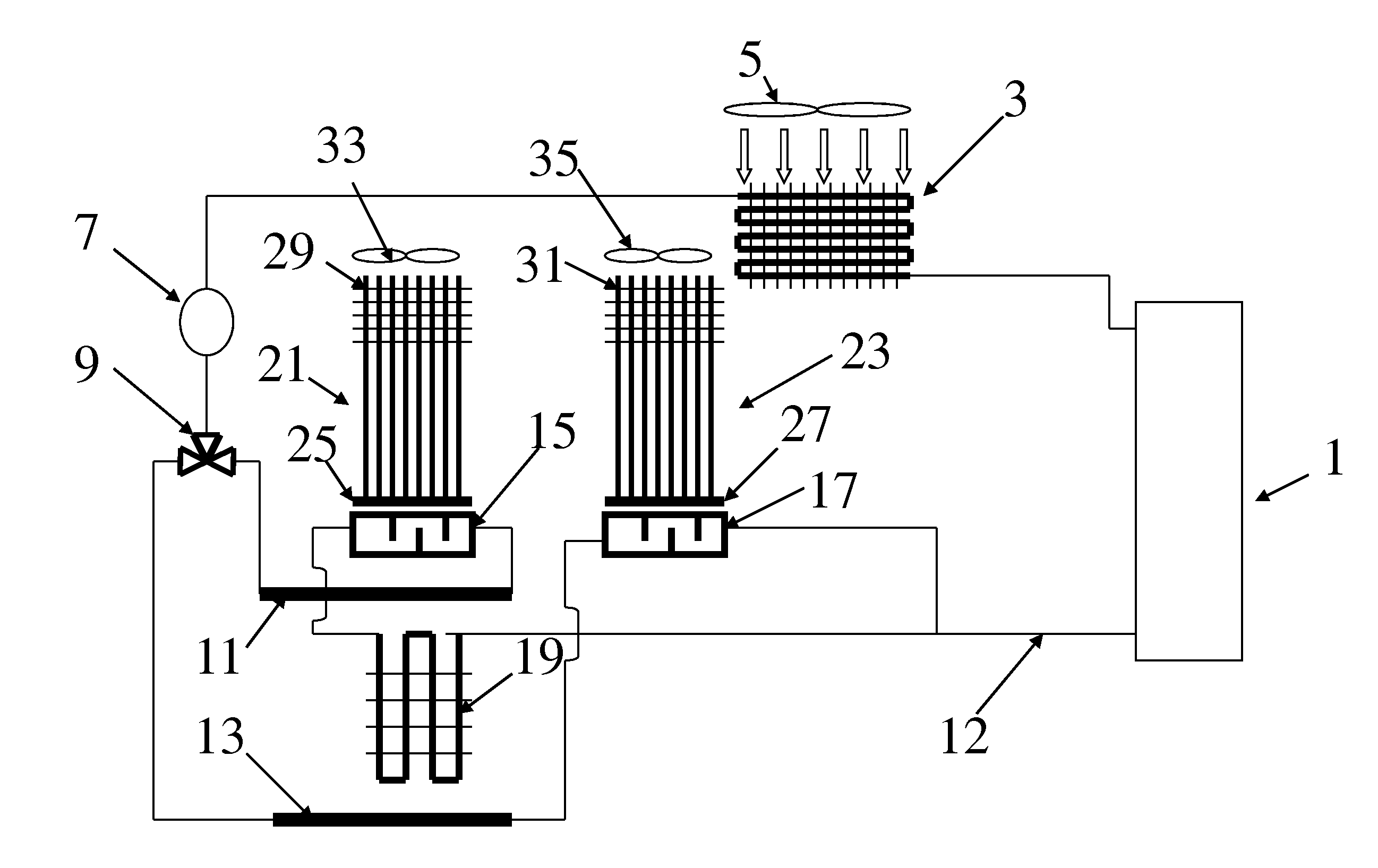

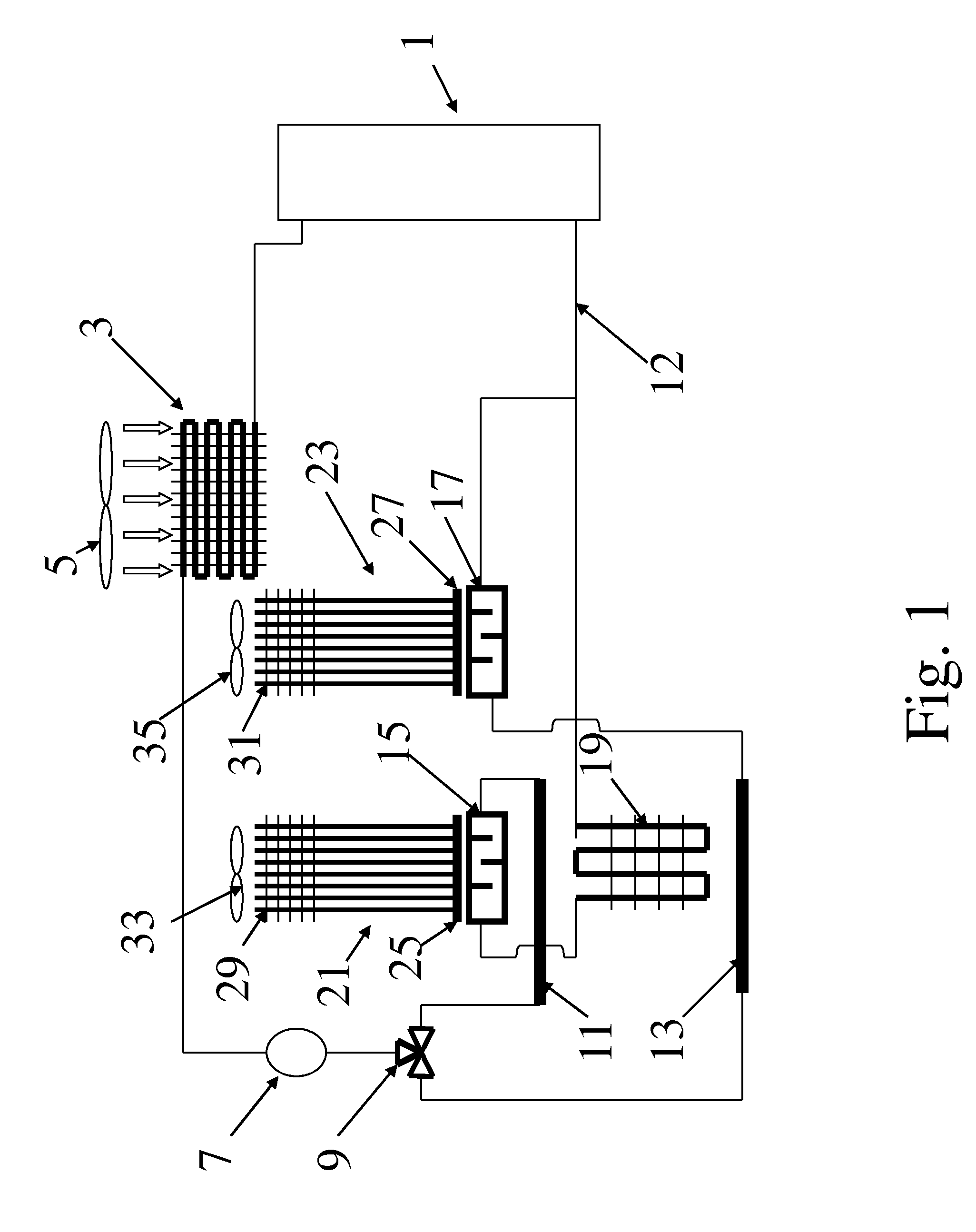

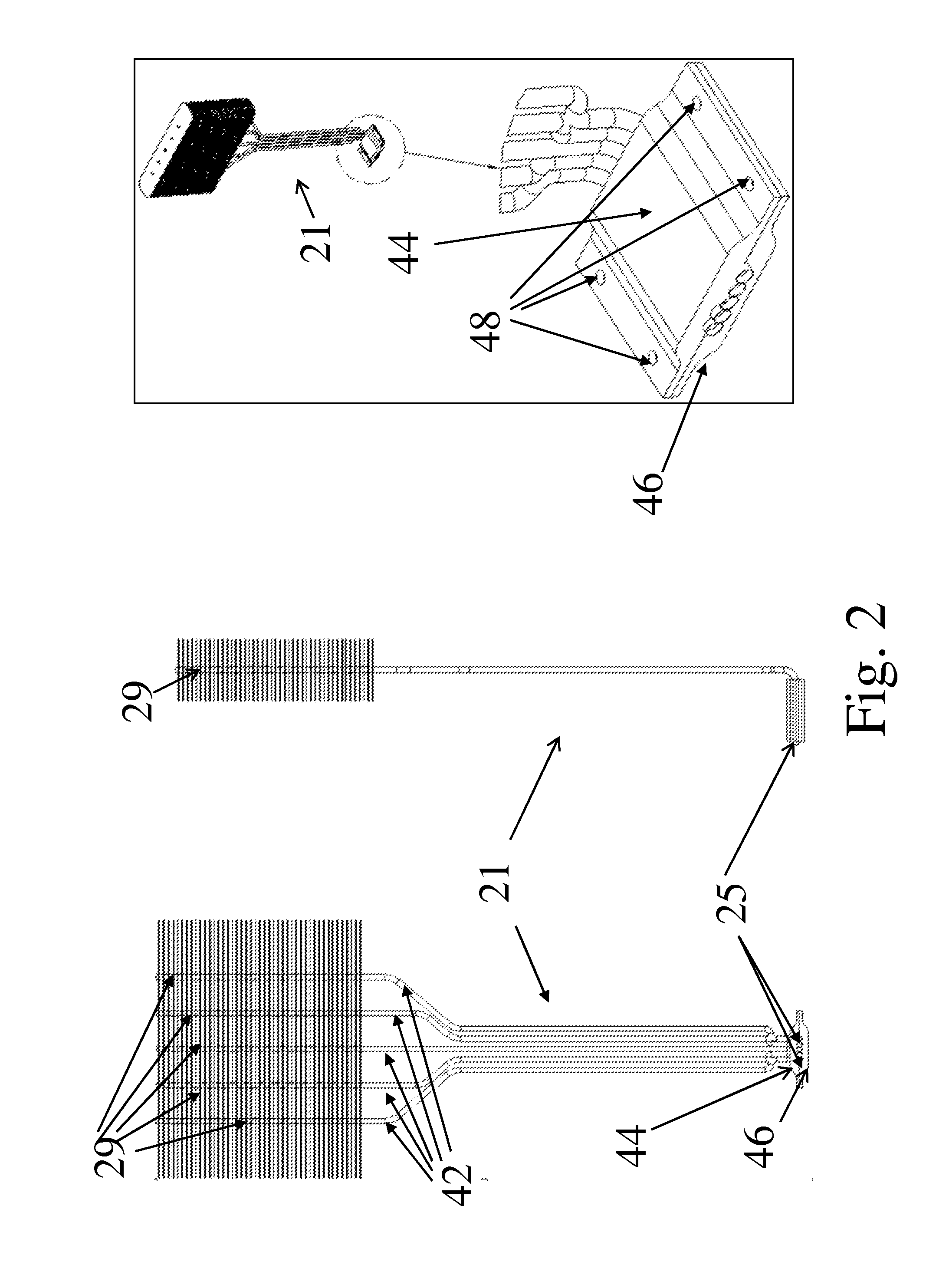

[0031]FIG. 1 shows sealed system schematics of a refrigerator with a heat pipe. Compressed gaseous refrigerant after compressor 1 flows to condenser 3 wherein high-pressure refrigerant cools down and condenses rejecting heat to airflow driven by fan 5. Liquid refrigerant through dryer 7 flows to multi-way valve 9. The valve depicted in FIG. 1 is a 3-way valve. However, it may be 2, 4, 5, N-way valve, or may be no valve at all. The 3-way step motor valve of Sanyo can be used as the 3-way valve depicted in FIG. 1. After valve 9 liquid refrigerant flows to expansion devices 11 and 13 that, for example, may be capillary tubes, and further to an evaporator that consists from several sections including cold plate sections 15, 17, and a conventional evaporating section 19. Cold plates 15, 17 are configured to have refrigerant flow therethrough to absorb heat and wherein at least a part of liquid refrigerant evaporates. Each cold plate section has a surface that is in heat transfer relation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com