Refrigeration apparatus

a refrigeration apparatus and refrigeration technology, applied in the field of space cooling systems, to achieve the effect of maximizing the sub-cooling of main liquid, less time, and improving the life span of compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Refrigeration Mode:

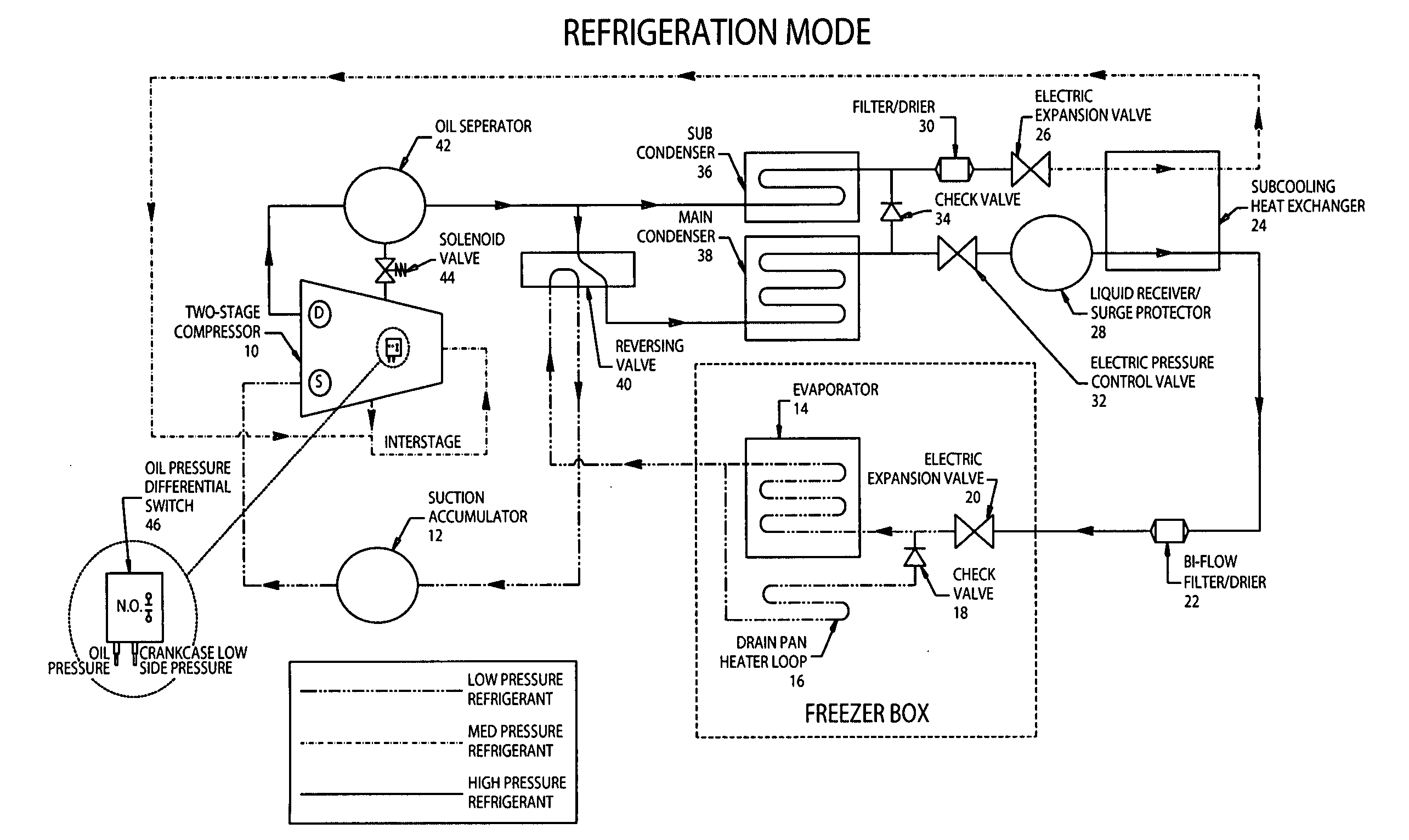

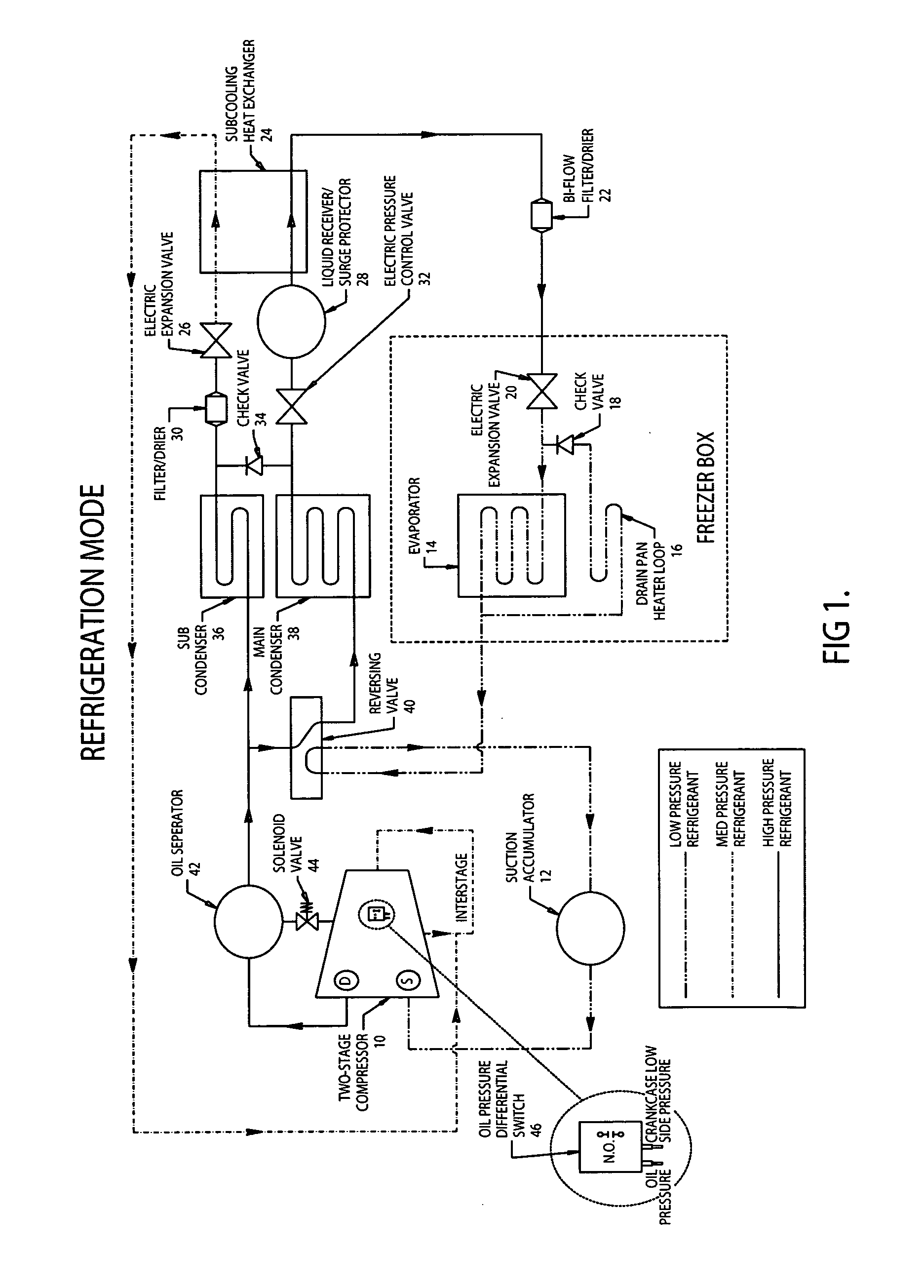

[0017]As shown in FIG. 1, invention utilizes two-stage reciprocating compressor 10. Refrigerant (not shown) is compressed by compressor 10. The temperature and pressure of the refrigerant is raised. The hot pressurized refrigerant gas then flows through the oil separator 42. The refrigerant oil is then separated by 42 and discharged back to the compressor 10 crankcase. Oil return solenoid valve 44 is powered with the synchronization of the compressor 10. When compressor 10 is in operation, solenoid valve 44 is open allowing oil to flow through.

[0018]The refrigerant after oil separator 42 is diverted into two directions. The first direction goes to the main circuit condenser 38 through the four way reversing valve 40. The second direction is to the sub-circuit condenser 36.

[0019]The majority of the high-pressure refrigerant goes to main condenser 38 and is condensed into a liquid state. Electric pressure control valve 32 is used to modulate the pressure of the refr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com