Oil cooler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

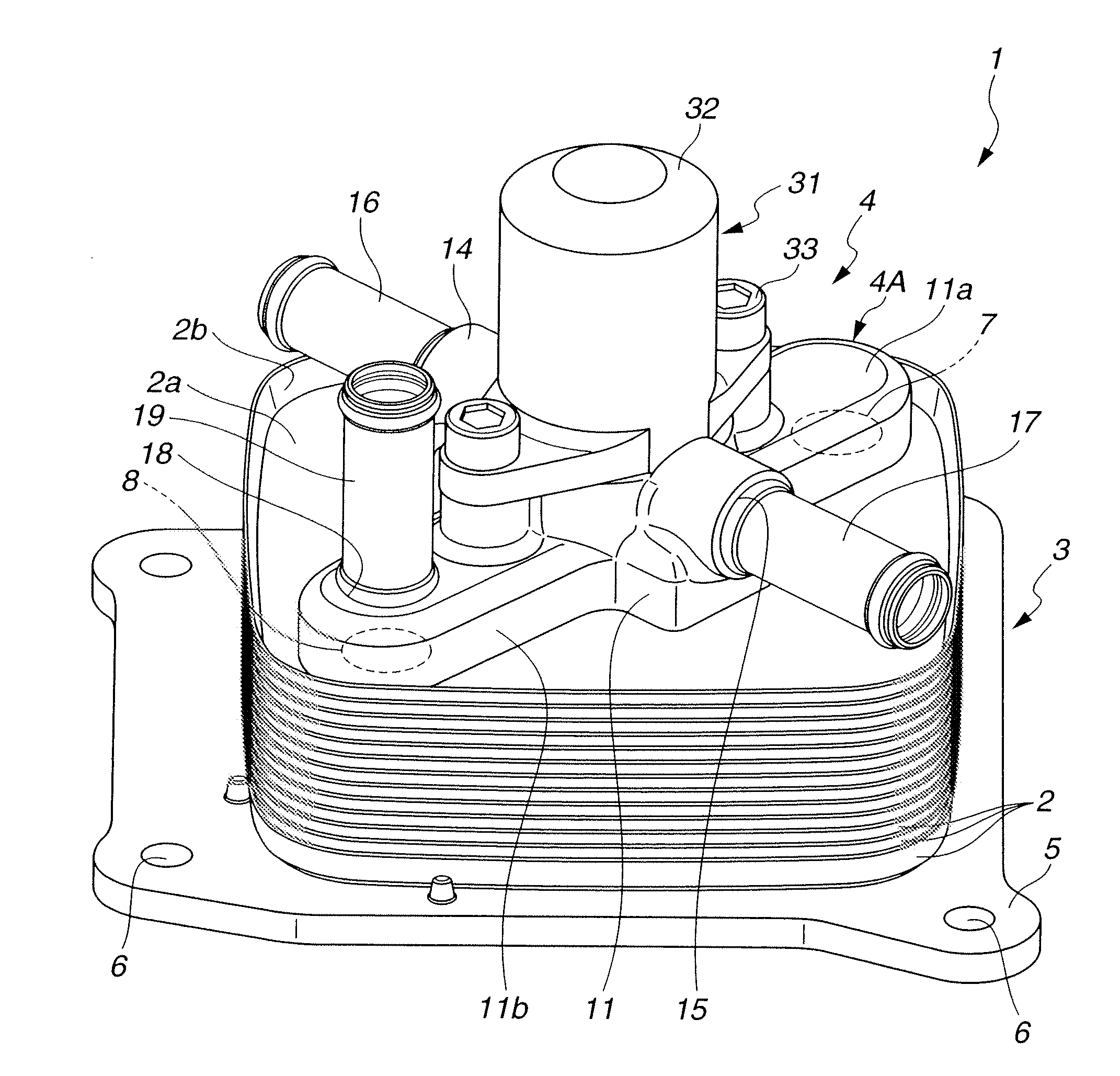

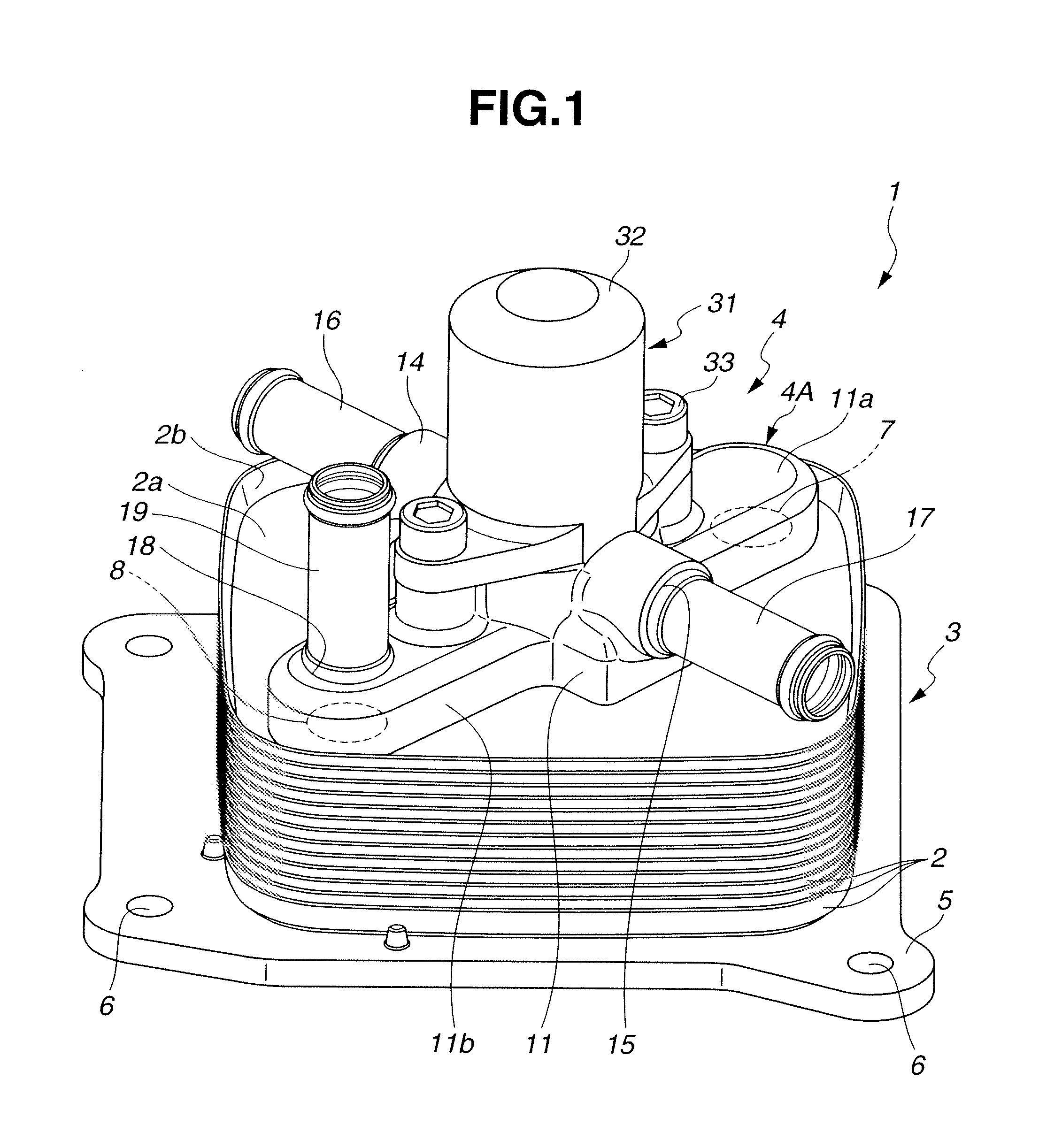

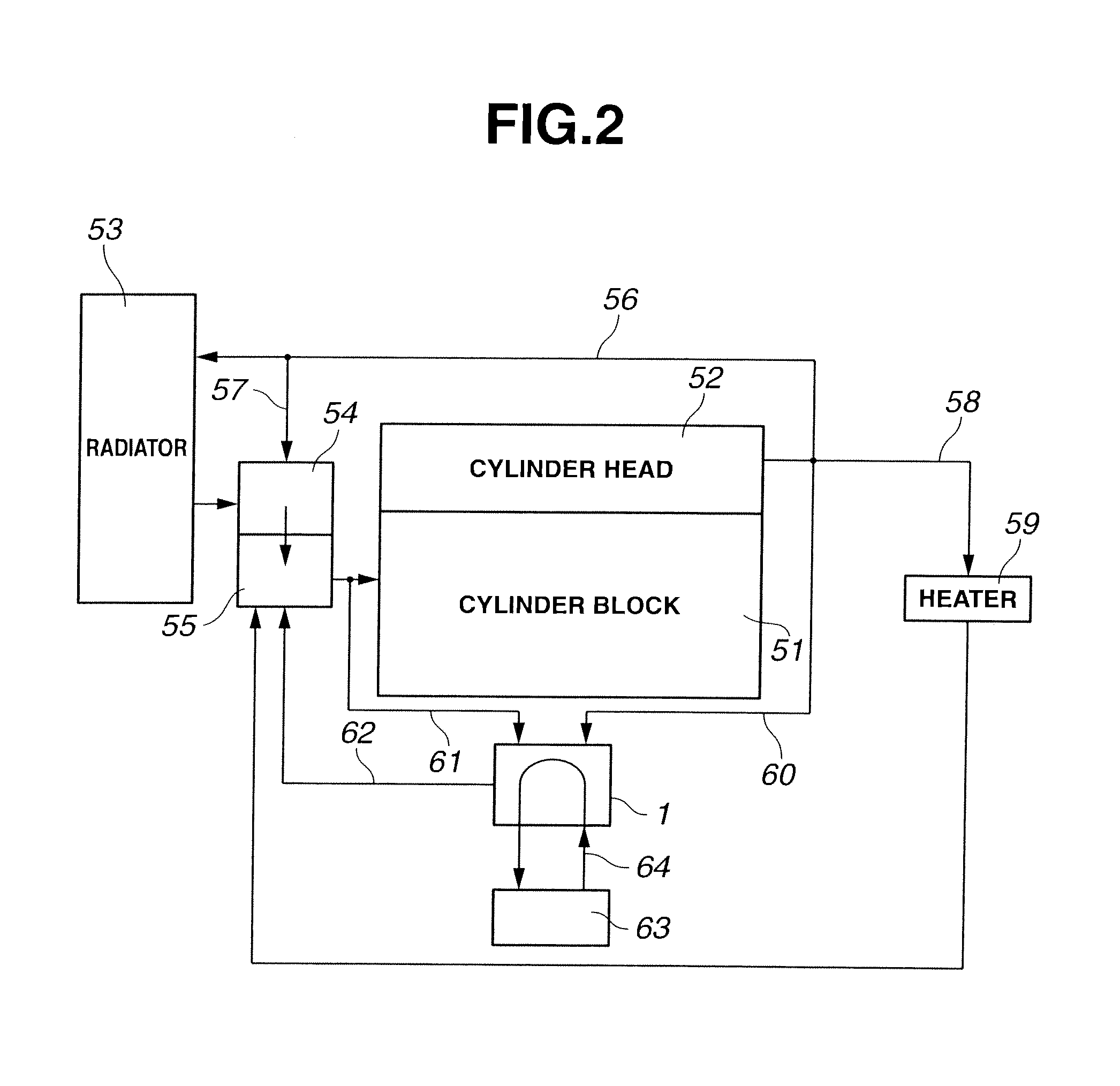

[0024]Referring now to FIG. 1 of drawings, an embodiment of an oil cooler according to the present invention is illustrated by the reference numeral 1. The oil cooler 1 in this embodiment is for cooling hydraulic oil of an automatic transmission of an automotive vehicle. The oil cooler 1 is used upon being incorporated in a cooling system for an internal combustion engine of the automotive vehicle as schematically illustrated in FIG. 2.

[0025]As shown in FIG. 2, the internal combustion engine is provided with a basic coolant circulation system which includes water jackets formed respectively in a cylinder block 51 and a cylinder head 52. A radiator 53 is fluidly connected to the water jackets. A thermostatic valve 54 is fluidly connected to the water jackets and the radiator 53. A water pump 55 is fluidly connectable to the water jackets and the radiator 53. Coolant whose temperature has become high upon receiving heat of various parts of the internal combustion engine is taken out f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com