Reciprocating Compressor Wrist Pin Bearing and Lubrication Passageway

a compressor and wrist pin technology, applied in the direction of connecting rod bearings, liquid fuel engines, positive displacement liquid engines, etc., can solve the problems of inability to design on the basis of friction, small space inside the piston, and poor wear characteristics, so as to achieve better wear characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

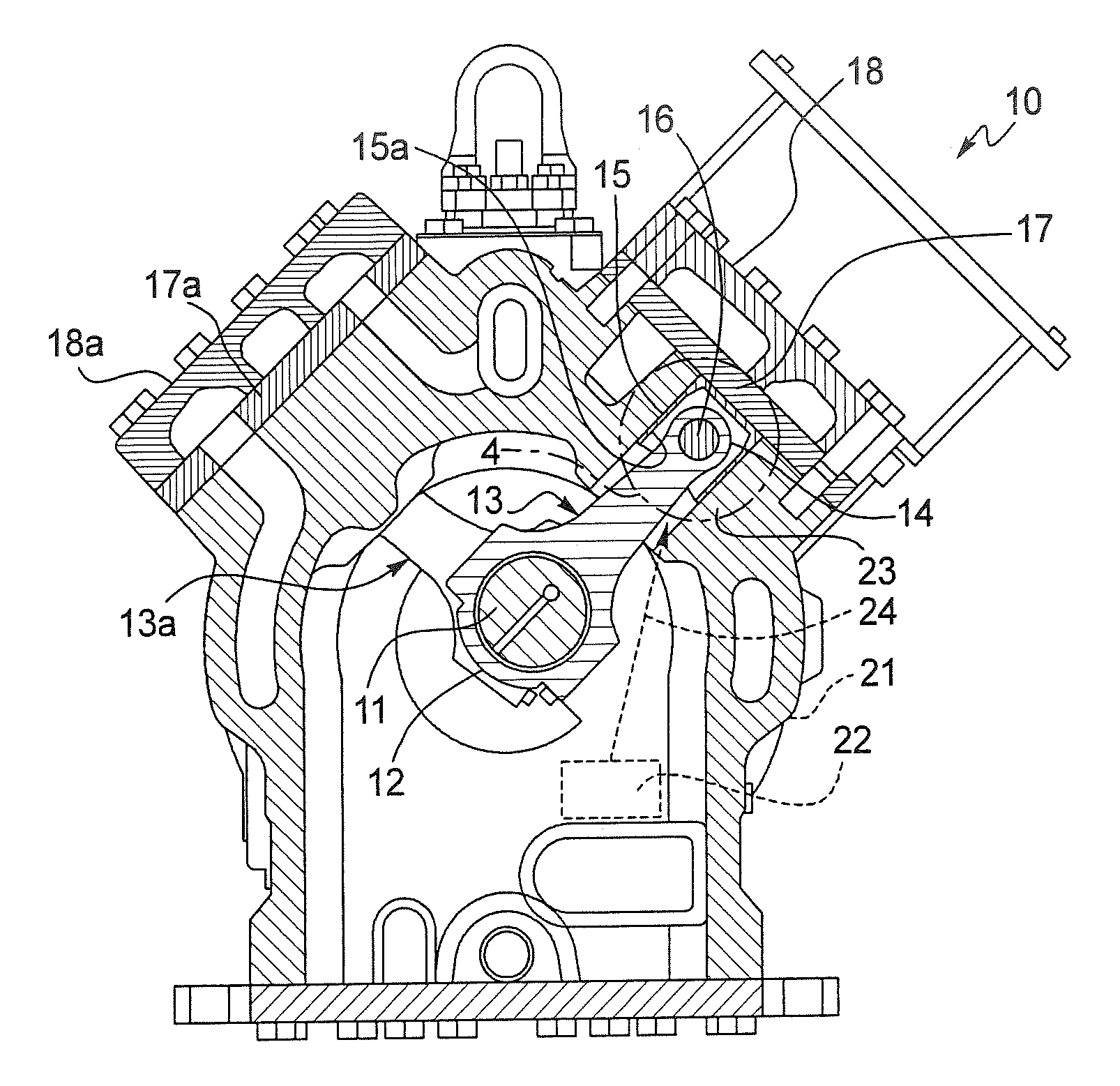

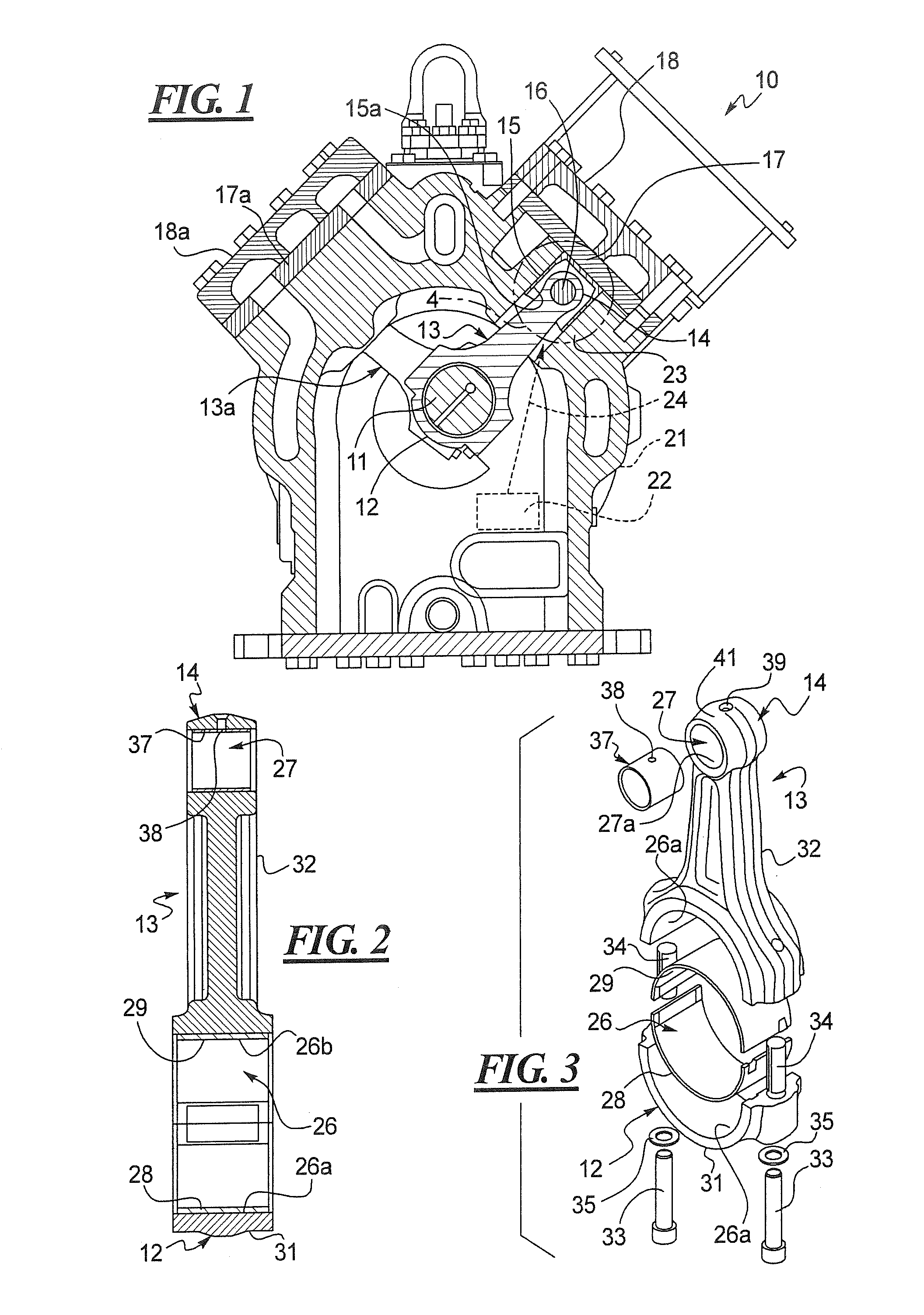

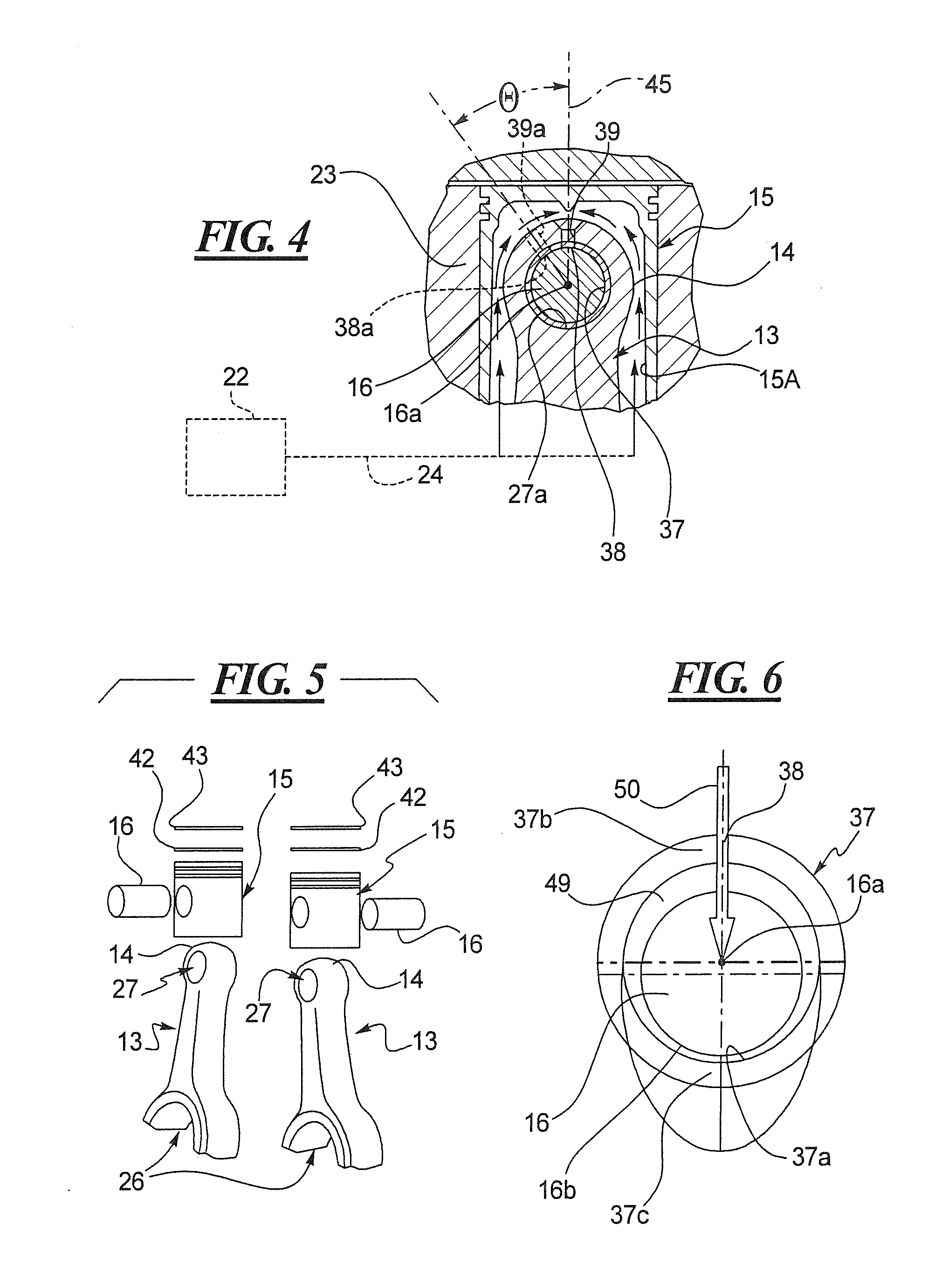

[0023]A compressor 10 is illustrated in FIG. 1 with a motor (not shown) that drives the crankshaft (not shown) that rotates the eccentric 11 received within the proximal ends 12 of the connecting rod 13. The connecting rod 13 includes a distal end 14 that is connected to a piston 15 by a wrist pin 16, as best seen in FIGS. 4-5. While only a single connecting rod 13 is illustrated in FIG. 1, compressors such as those shown at 10 in FIG. 1 typically include four connecting rods 13 or two pairs of connecting rods 13, one such pair of parallel connecting rods 13 being illustrated in FIG. 5. Another connecting rod 13a is also illustrated in FIG. 1 and is disposed in a parallel relationship with an additional connecting rod 13a (not shown). The connecting rods 13, 13a may be fabricated from aluminum, an aluminum alloy, various steels, cast irons or magnesium alloys.

[0024]The pistons 15 shown in FIGS. 1 and 5 move towards and away from the valve plate 17 and head 18 to compress a gas, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com