Heat dissipation structure

a heat dissipation module and heat dissipation technology, applied in the direction of lighting and heating apparatus, basic electric elements, semiconductor devices, etc., can solve the problems of constant shrinkage of electronic products, heat generation, and inability to meet the requirements of conventional heat dissipation modules, so as to solve the disadvantage of undesirable cooling efficiency of conventional techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

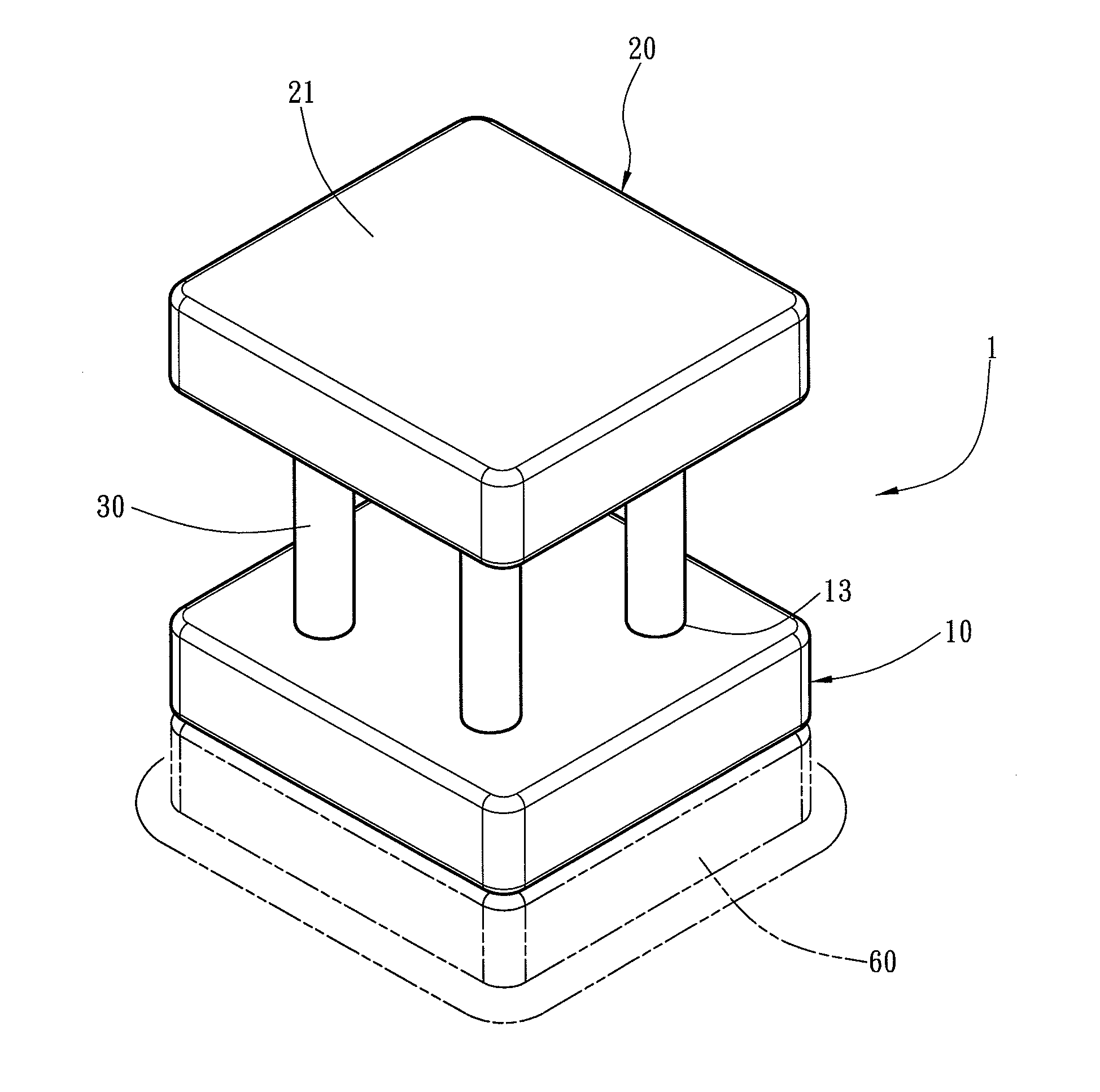

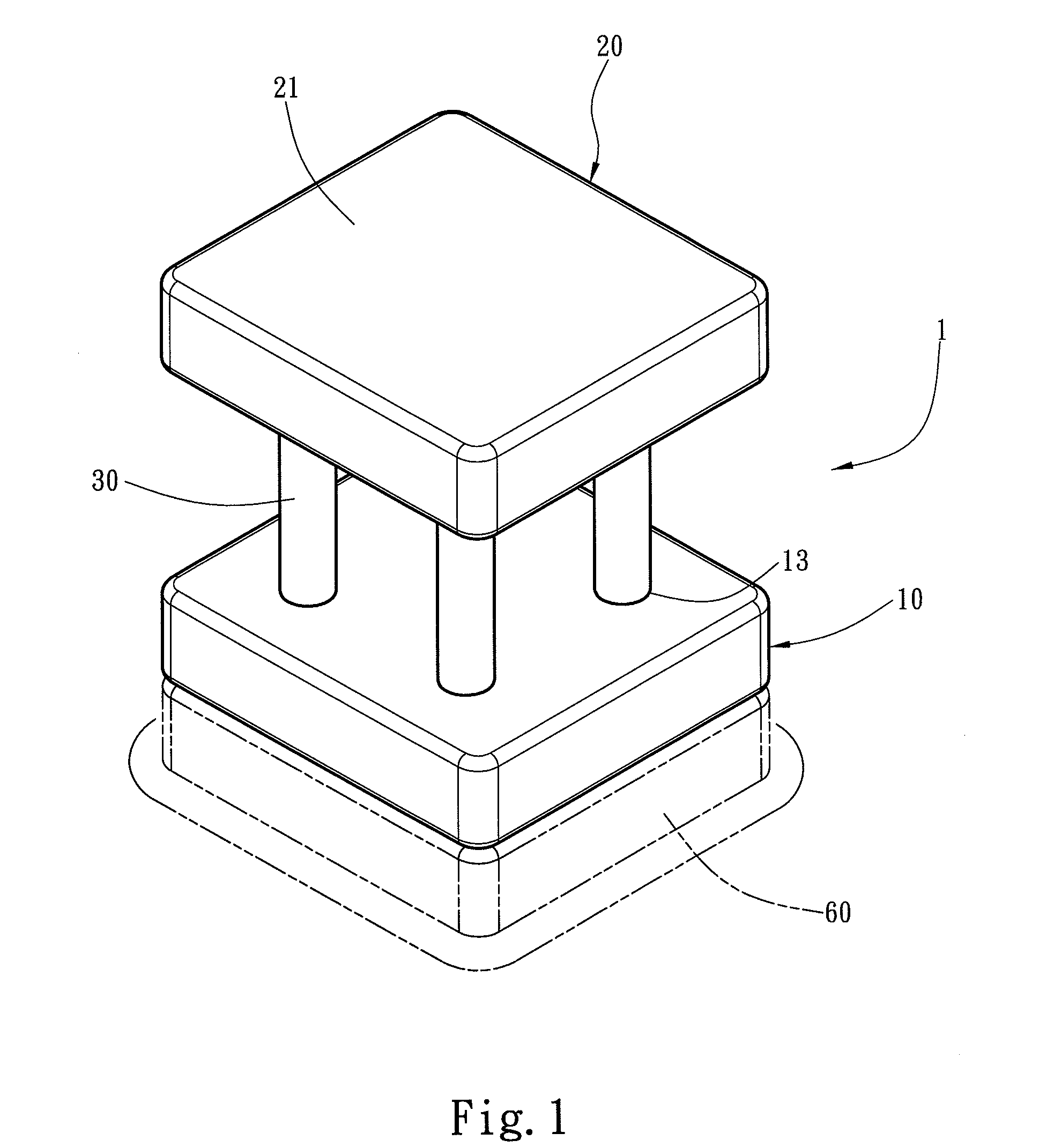

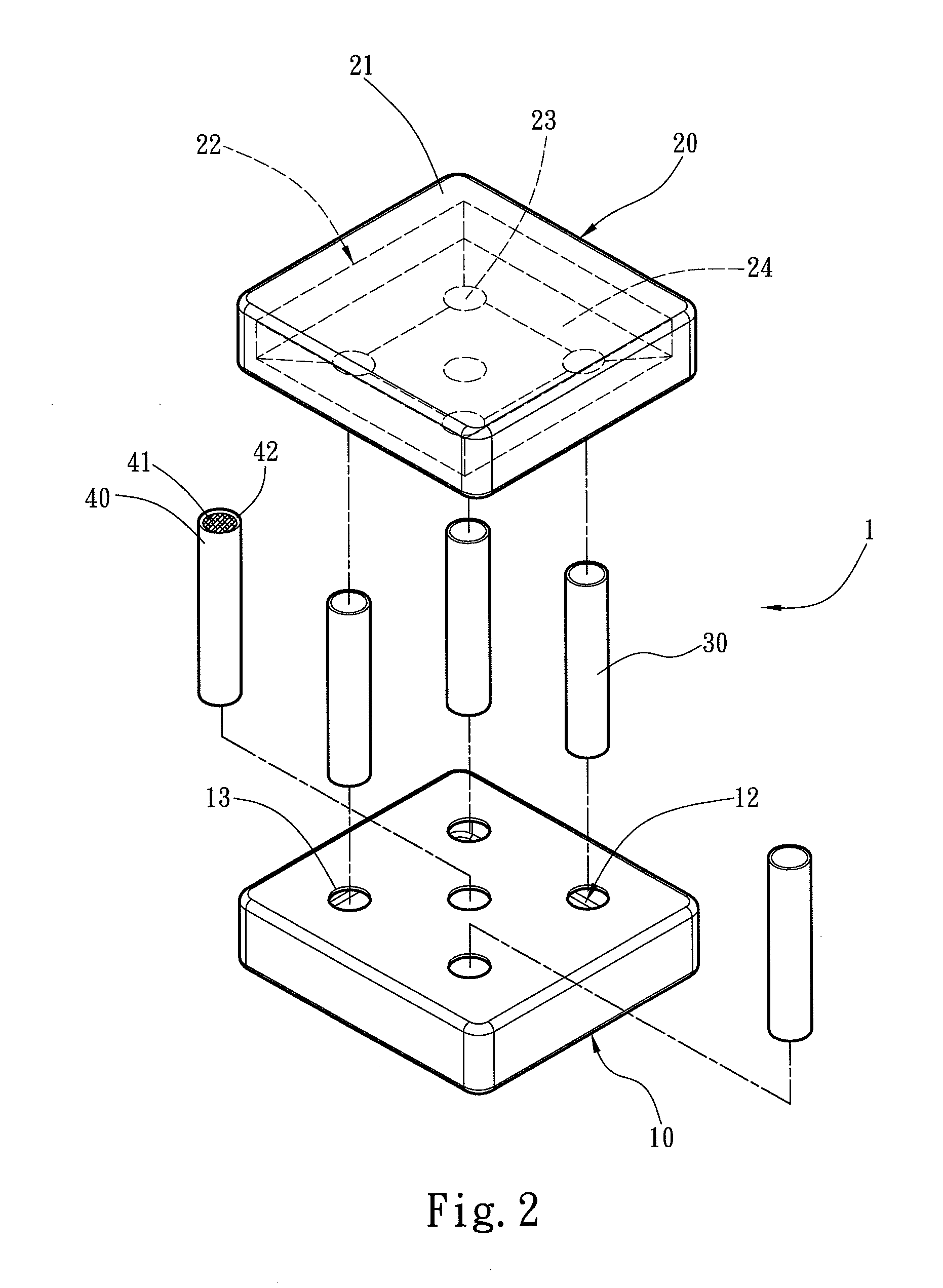

[0015]Please refer to FIGS. 1 and 2, the present invention aims to provide an improved heat dissipation structure 1 mainly adopted on an electronic element 60 to dissipate heat thereof.

[0016]The heat dissipation structure 1 includes a heat absorber 10, a heat sink 20 and a plurality of first conduits 30 bridging the heat absorber 10 and heat sink 20. The heat absorber 10 is installed on the surface of the electronic element 60 to absorb heat generated thereon. The heat absorber 10 is a hollow casing containing a first chamber 12. The heat sink 20 also is a hollow casing containing a cooling surface 21 and a second chamber 22 to perform heat exchange. The heat absorber 10 and heat sink 20 have respectively a plurality of first coupling orifices 13 and second coupling orifices 23 to couple with the first conduits 30. Thus forms the main structure of the invention.

[0017]Referring to FIGS. 3A and 3B, the heat absorber 10 is mounted onto the electronic element 60 with a contact surface 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com