Reduced circuit trace roughness for improved signal performance

a circuit trace and roughness technology, applied in the field of signal transmission, can solve the problems of reducing signal reach and performance, conductive circuit traces often exhibit surface roughness, etc., and achieve the effect of improving signal performance, reducing both lateral and transverse fabrication roughness, and improving high-speed signal propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

[0017]The following description is intended to convey a thorough understanding of the present invention by providing a number of specific embodiments and details involving polishing conductive circuit traces in circuit boards and other circuit devices. It is understood, however, that the present invention is not limited to these specific embodiments and details, which are exemplary only. It is further understood that one possessing ordinary skill in the art, in light of known systems and methods, would appreciate the use of the invention for its intended purposes and benefits in any number of alternative embodiments, depending upon specific design and other needs.

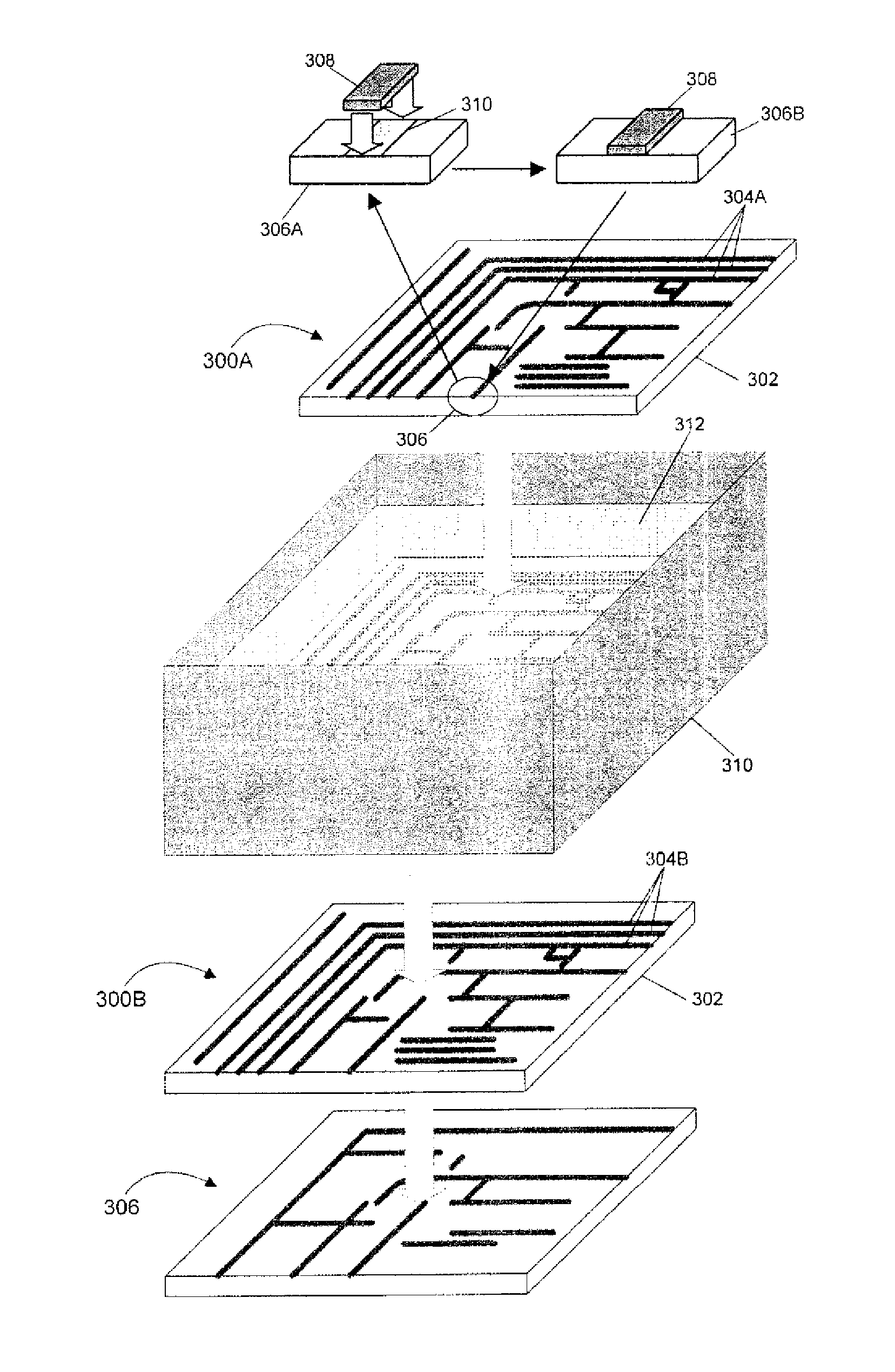

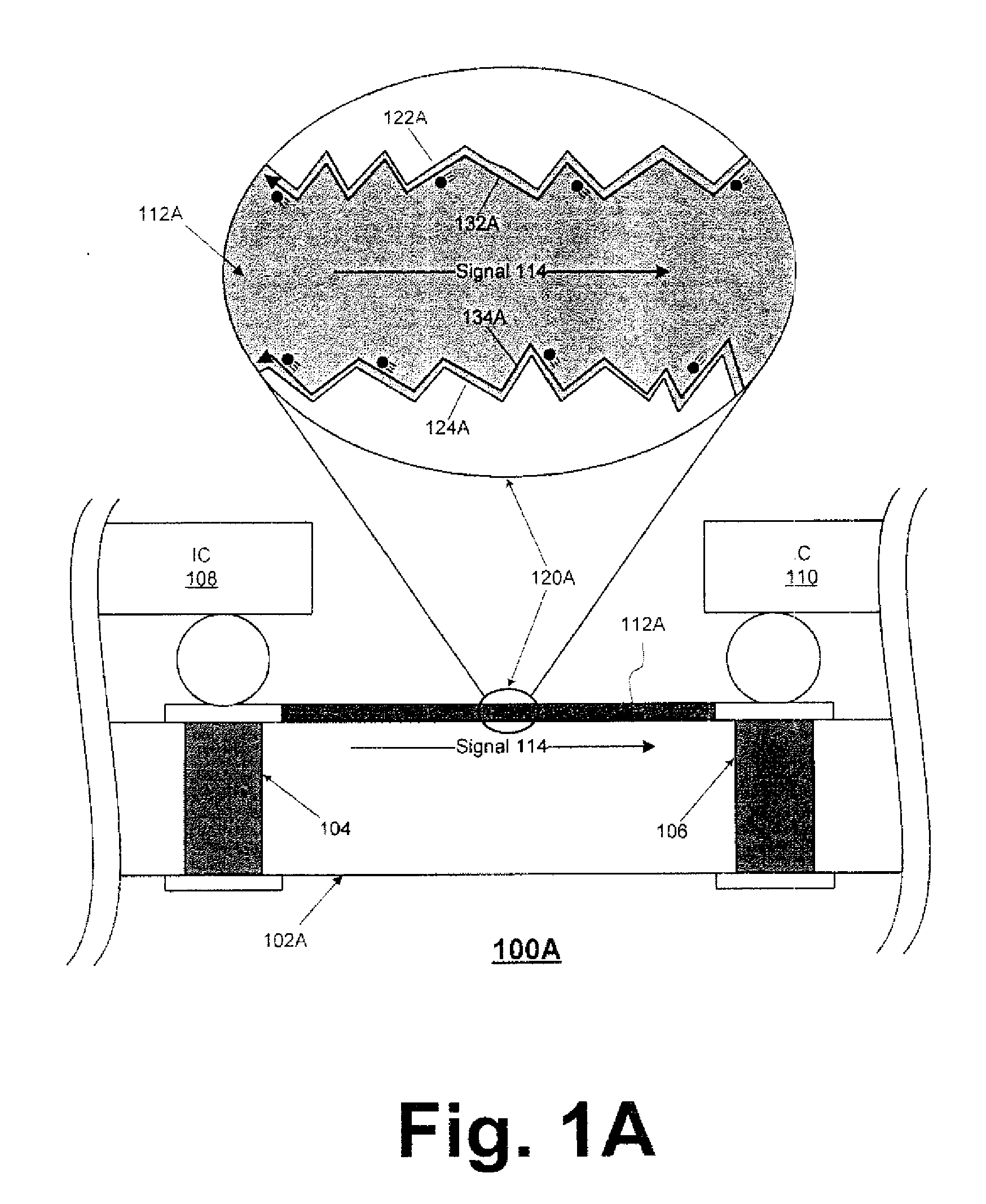

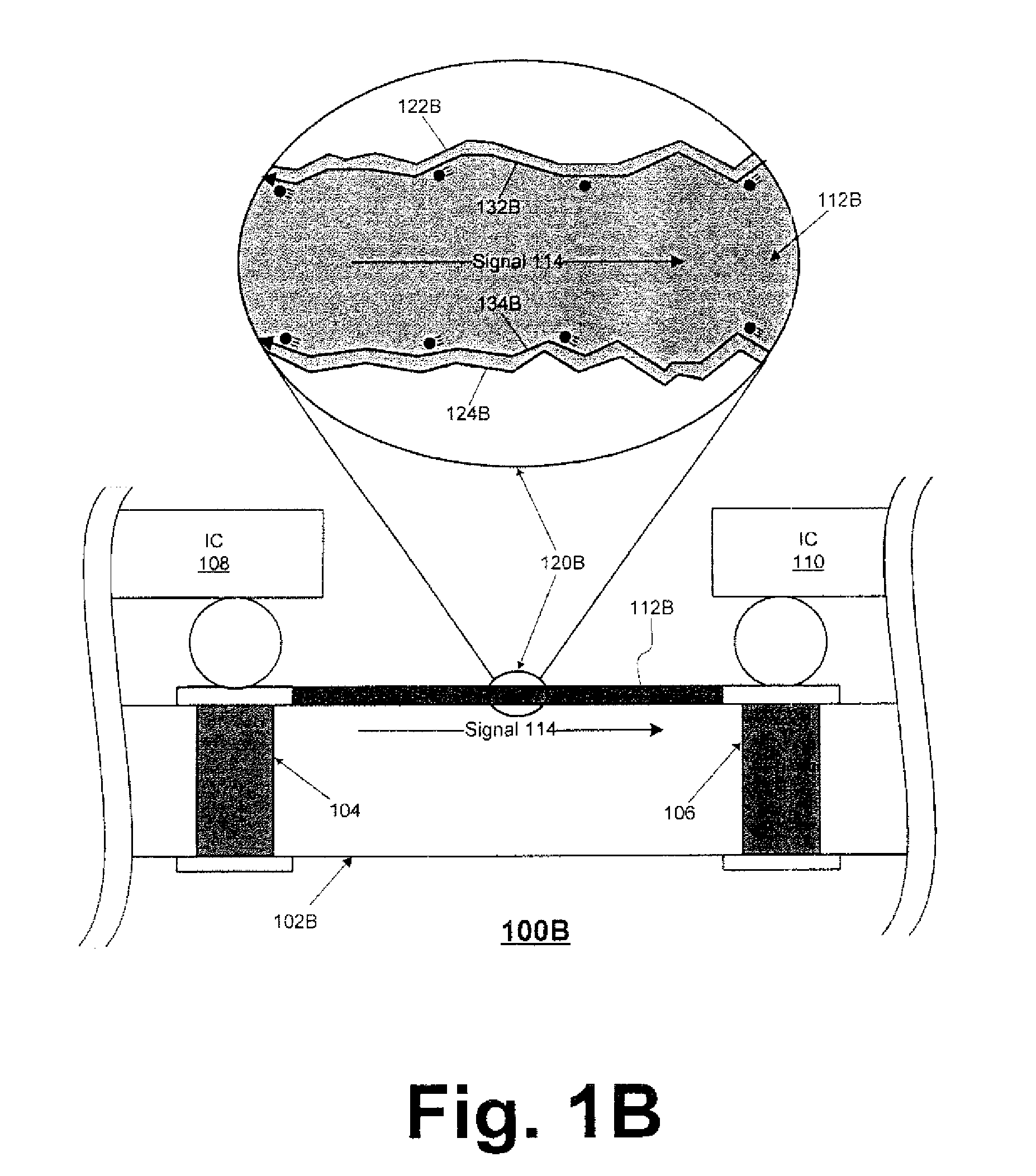

[0018]FIGS. 1A-3 illustrate various exemplary techniques for polishing circuit traces of a printed circuit board (PCB) to improve the performance of signals transmitted therein. In at least one embodiment, one or more surfaces of one or more conductive circuit traces of a PCB may be polished to reduce their surface roughne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| skin depth | aaaaa | aaaaa |

| skin depth | aaaaa | aaaaa |

| skin depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com