Touch panel touching sensing integration structure

A touch panel and touch sensing technology, applied in the input/output process of data processing, instruments, electrical and digital data processing, etc. The effect of conductivity, increasing signal transmission capacity, and increasing market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

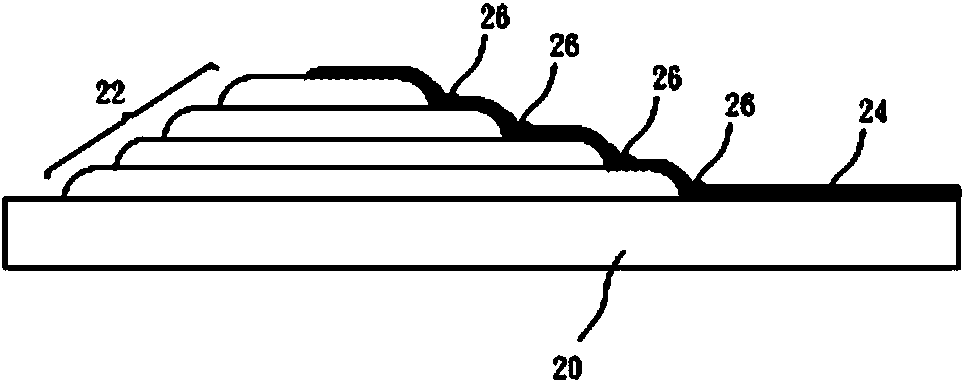

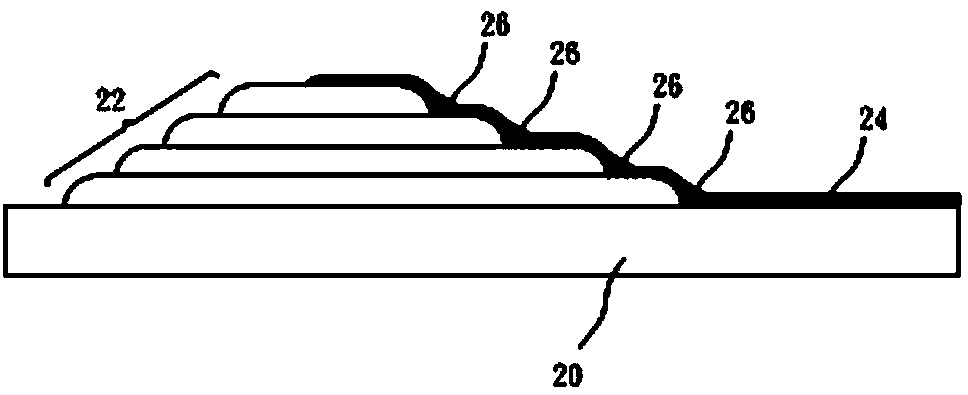

[0027] With the vigorous development of the touch panel industry in recent years, in order to make the touch panel more humanized and convenient, it has gradually entered the small, compact, light and thin generation. Therefore, in order to meet the design requirements of lightness and low price, and greatly Simplify the structure of the touch sensing layer and lower the production cost. The touch sensing integrated structure of the touch panel designed in the present invention is a monolithic glass touch panel, and a piece of glass is used as the surface cover glass and the touch panel. The substrate of the control sensor, and through the design ingenuity that does not affect the visibility of the panel, the product is more reliable, in order to increase the market competitiveness.

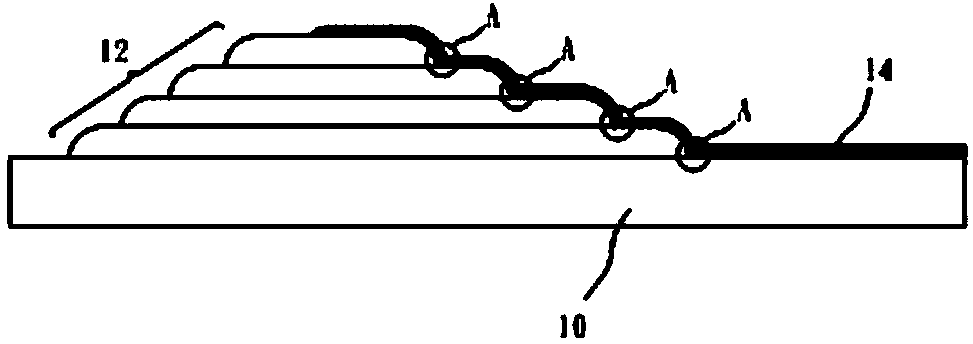

[0028] Such as figure 2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com