Gear pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

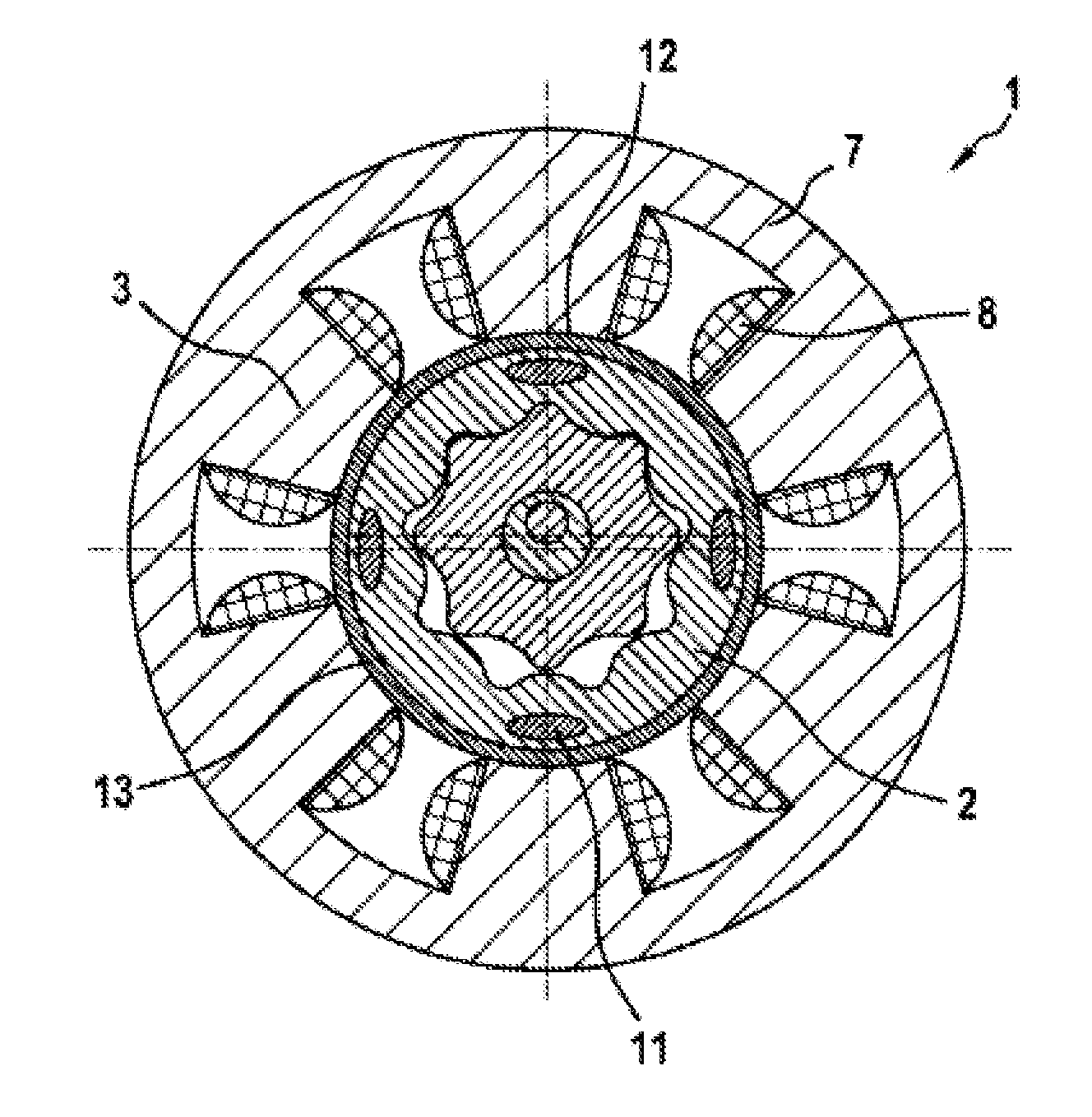

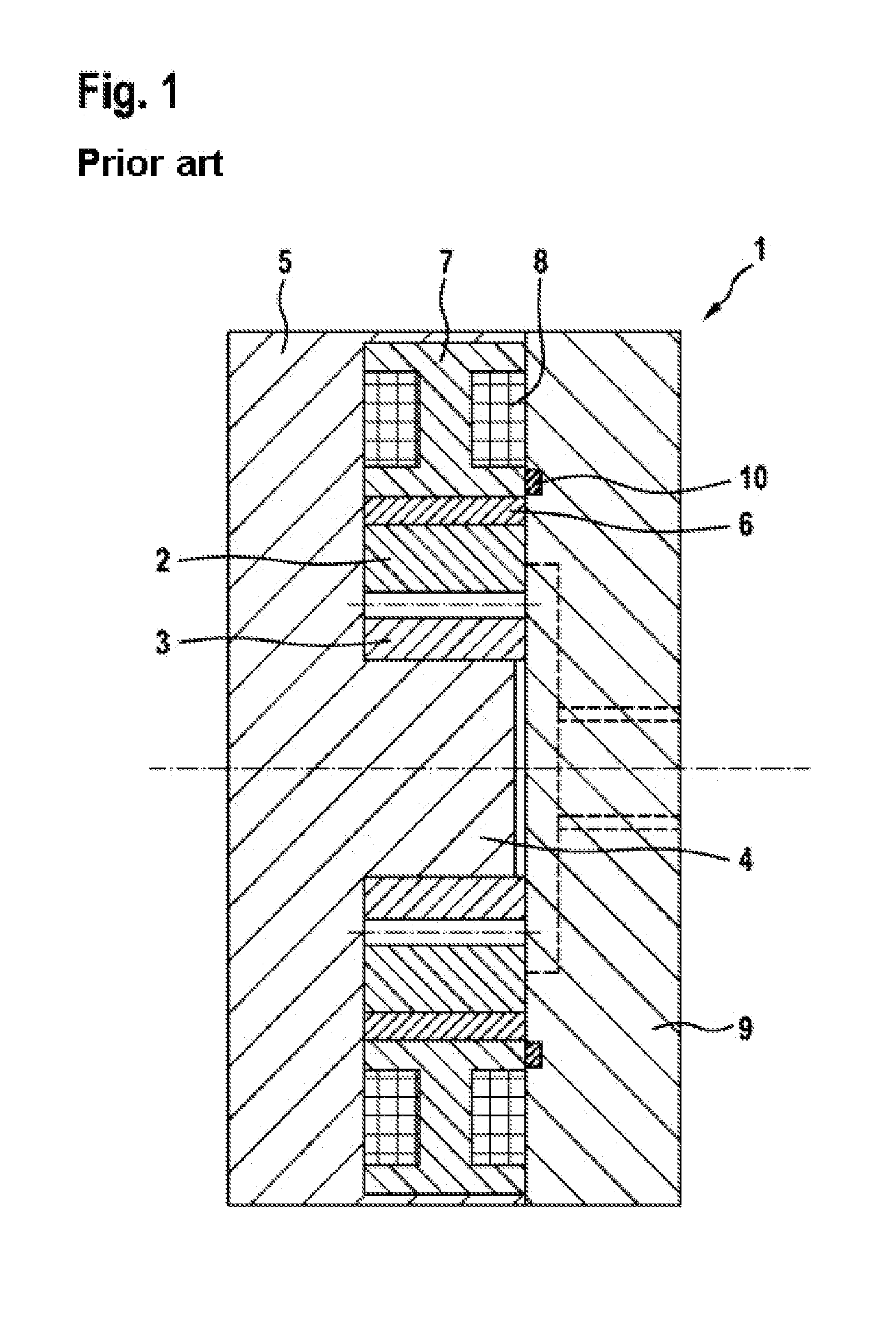

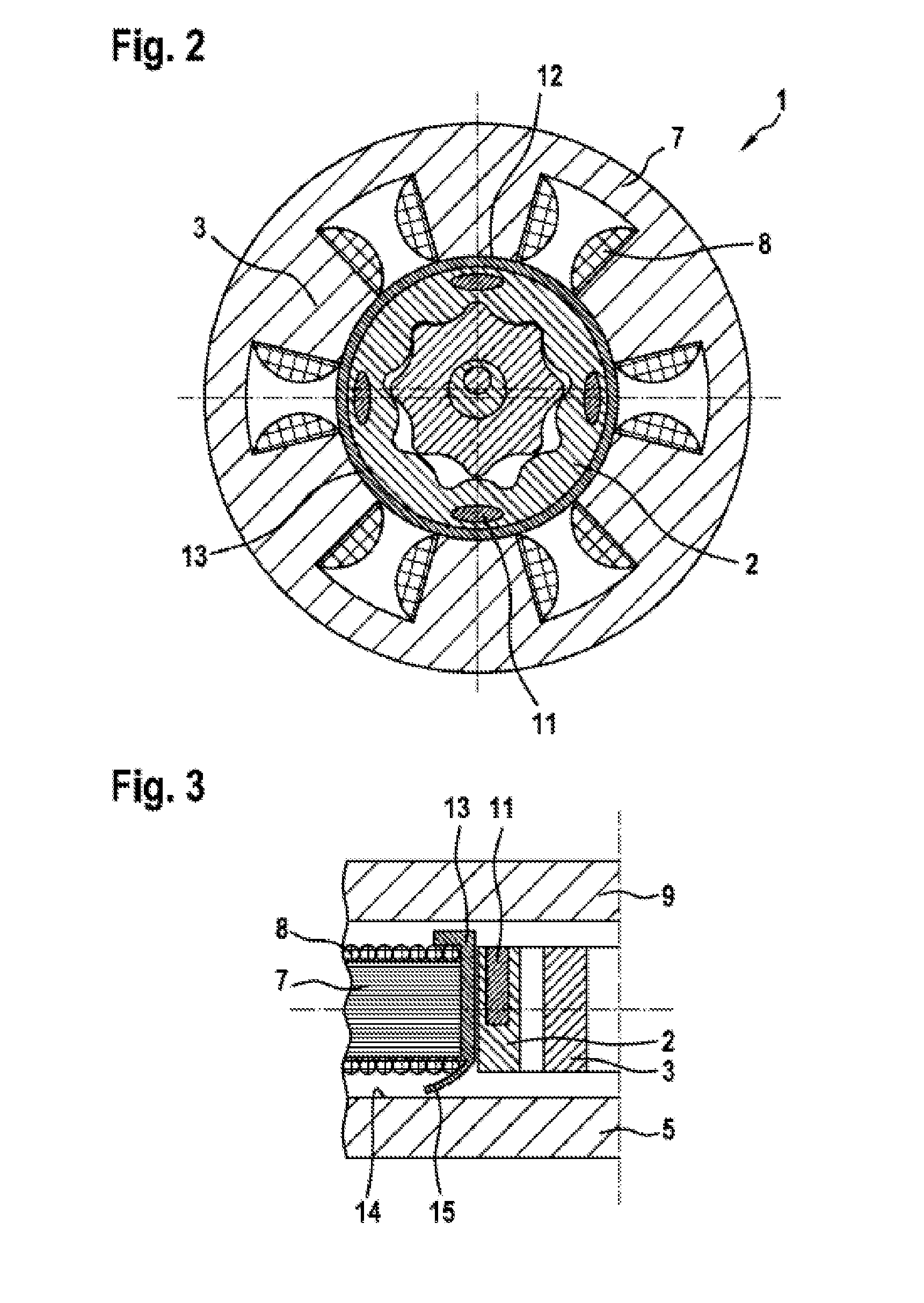

[0021]FIG. 1 shows a section though an internal gear pump 1 according to the prior art. The internal gear pump 1 comprises a pair of gearwheels which comprises an internally toothed annular gear 2 and an externally toothed gearwheel 3. The gearwheel 3 is arranged in a rotatable manner on a bearing pin 4 eccentrically with respect to the annular gear 2. If the annular gear 2 is made to rotate, the external tooth system of the gearwheel 3 meshes with the internal tooth system of the annular gear 2 and generates a volumetric delivery flow of the fluid, in which the tooth system runs. The pair of gearwheels comprising the annular gear 2 and the gearwheel 3 is arranged in a housing 5, with the bearing pin 4 being formed in one piece or integrally with the housing 5. Furthermore, the annular gear 2 is connected to an annular magnet 6 in a rotationally fixed manner, with the annular magnet 6 extending around the annular gear 2 in a radially encircling manner. The annular magnet 6 runs in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com