Composite current collector and methods therefor

a current collector and composite technology, applied in the field of current collectors, can solve the problems of inability to deep cycle applications, premature capacity loss of the cell, etc., and achieve the effects of improving the resistance to oxidation and conductivity, reducing the cost of production, and improving the power-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

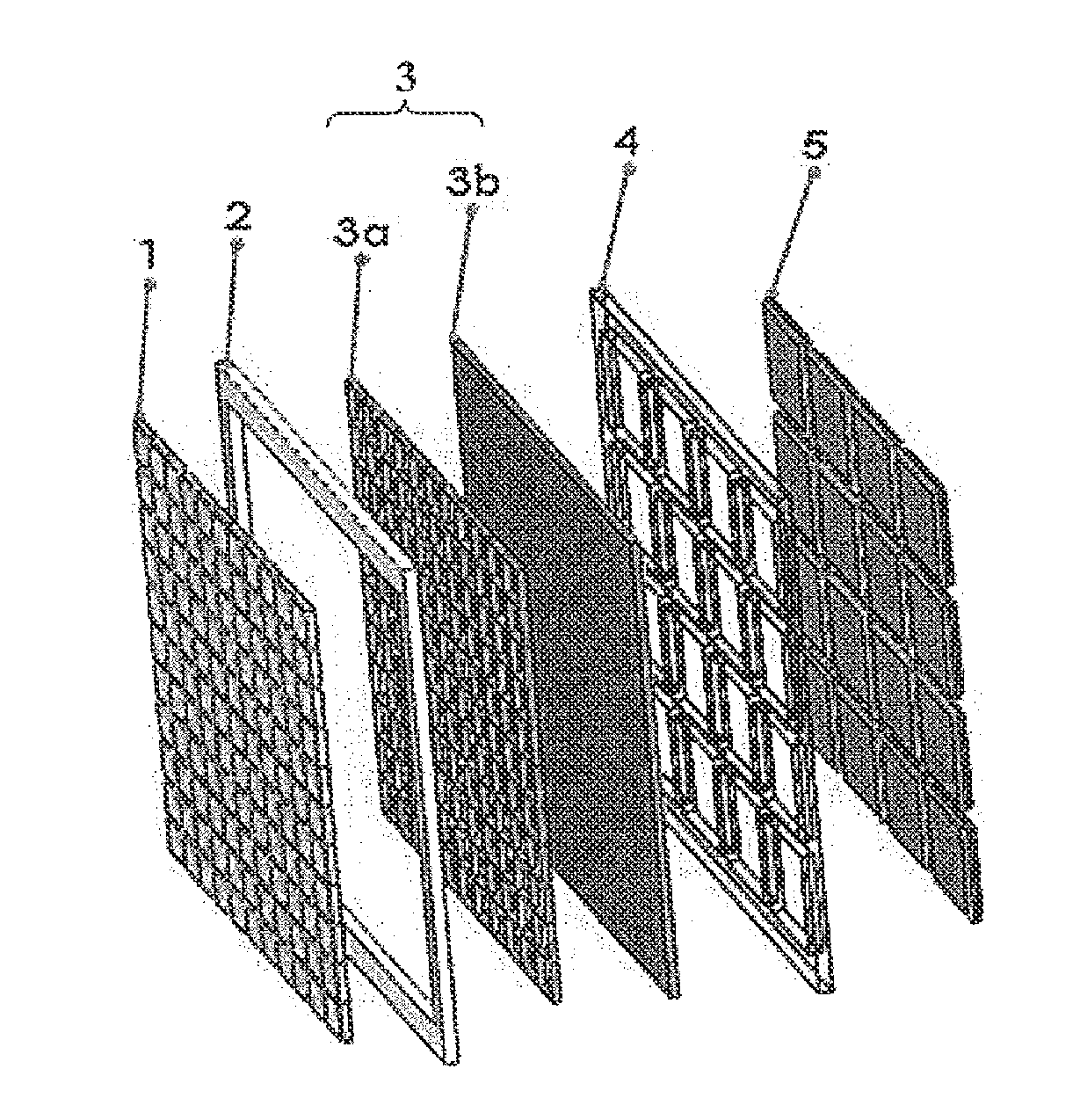

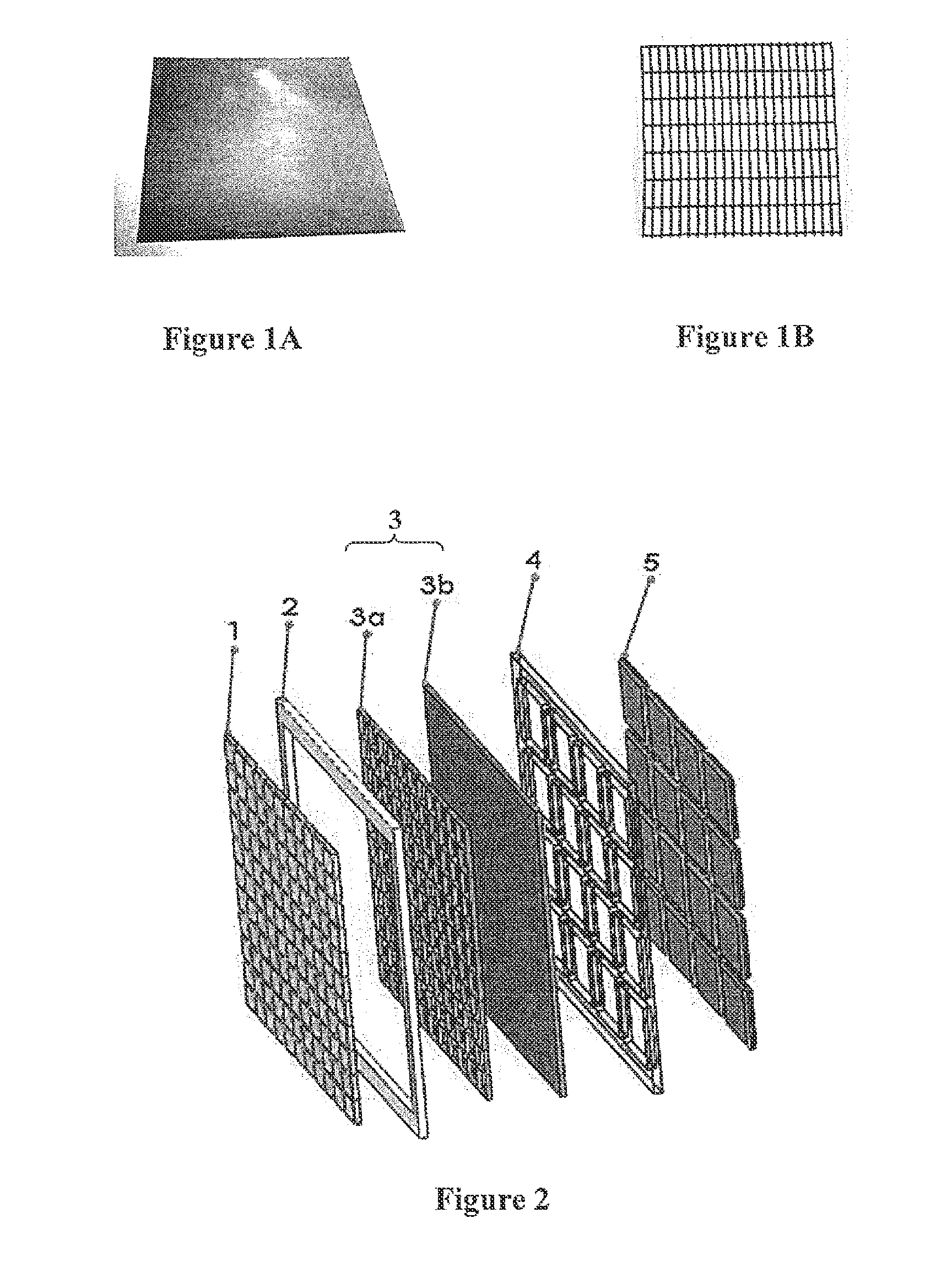

Method used

Image

Examples

examples

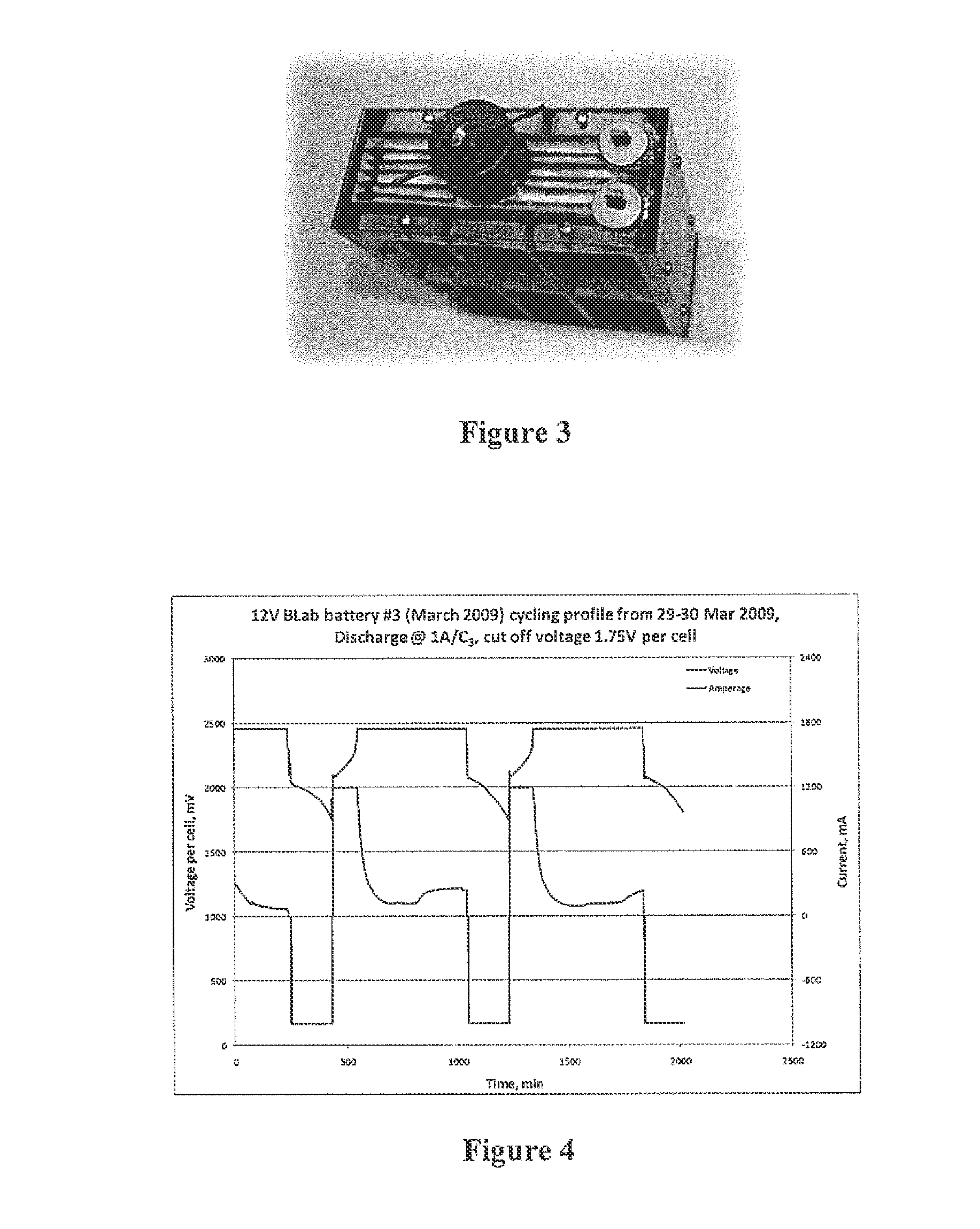

[0033]In a typical experiment, a batch of 12V BLABs was prepared in which the substrates and the grids of the current collectors were welded to each other. These first generation batteries have proven the feasibility and advantages of electroformed composite current-collectors. It is expected that electroformed monolithic current collectors will provide the same or even further improved results. The cycling performance of such BLABs appeared to be steady as can be readily taken from the data below. Moreover, the BLABs demonstrated desirable capacity parameters as can be taken from the data below. Based on these initial experiments and general configurations, the inventors have constructed various additional BLABs with the following characteristics:

[0034]Table 1 below depicts general parameters of the active materials while Table 2 below lists various design parameters for the lead substrate and grid. Table 3 below lists the weight of the BLAB components, and Table 4 lists an estimat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com