Prick-resistant explosion-proof polymer synthetic high-viscoelasticity rubber for tyre and preparation method thereof

A polymer and elastic glue technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problem that the cost of rubber materials should not be too high, the effect of tire repair is not ideal, and cannot be popularized and other problems, to achieve enhanced noise reduction and shock absorption effects, good resilience, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] An anti-puncture and anti-explosion polymer synthetic high-viscoelastic rubber material for tires is a mixture composed of the following components. In the mixture, the proportion of each component material is calculated as follows in parts by weight:

[0066] 28 parts by weight of butyl rubber, 47 parts by weight of polyisobutylene;

[0067] 20 parts by weight of softening oil (including 10 parts by weight of naphthenic oil, 5 parts by weight of paraffin oil, and 5 parts by weight of paraffin);

[0068] 17 parts by weight of thermoplastic elastomer resin;

[0069] 14 parts by weight of tackifying resin (including 10 parts by weight of rosin, 4 parts by weight of hydrogenated rosin glyceride derivatives);

[0070] 7.5 parts by weight of calcium carbonate;

[0071] 0.75 parts by weight of antioxidant (including β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecanyl propionate (antioxidant 1076) 0.5 parts by weight, tris(2, 0.2 parts by weight of 4-di-tert-butylphenyl) es...

Embodiment 2

[0079] An anti-puncture and anti-explosion polymer synthetic high-viscoelastic rubber material for tires is a mixture composed of the following components. In the mixture, the proportion of each component material is calculated as follows in parts by weight:

[0080] 10 parts by weight of butyl rubber, 60 parts by weight of polyisobutylene;

[0081] 15 parts by weight of naphthenic oil;

[0082] 20 parts by weight of thermoplastic elastomer resin;

[0083] Rosin 8 parts by weight;

[0084] 12 parts by weight of filler (including 6 parts by weight of talcum powder, 3 parts by weight of pottery clay, and 3 parts by weight of white carbon black);

[0085] 0.6 parts by weight of antioxidant (including β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate (antioxidant 1076) 0.2 parts by weight, tris(2, 0.2 parts by weight of 4-di-tert-butylphenyl) ester (antioxidant 168), 0.2 parts by weight of 2,2'-methylenebis(4-methyl-6-tert-butylphenol) (antioxidant 2246) );

[0086...

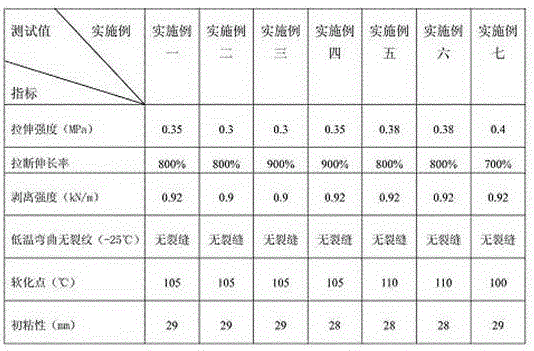

Embodiment 3 Embodiment 7

[0093] Embodiment 3-Embodiment 7 is a transformation of Embodiment 1 and Embodiment 2 of the present invention. The amount of each component of the anti-puncture and explosion-proof polymer synthetic high viscoelastic rubber material raw material for tires is the same as that of Embodiment 1. Implementation Compared with Example 2, it can also be increased or decreased, and it is also possible to decide whether to add fillers or dyes according to actual needs. Generally, the value range of each component is:

[0094] 6-50 parts by weight of rubber, 25-70 parts by weight of binder;

[0095] 5-25 parts by weight of softening oil, 5-30 parts by weight of SBS resin;

[0096] 3-25 parts by weight of tackifying resin, 0-15 parts by weight of filler;

[0097] 0.5-1 weight part of antioxidant, 0-0.1 weight part of dyestuff;

[0098] 5-20 parts by weight of solvent.

[0099] For the specific content of each component in each embodiment of the present invention, please refer to the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com