Cooling module for LED lamp

a technology of led lamps and cooling modules, which is applied in the direction of lighting and heating apparatus, tubular elements, point-like light sources, etc., can solve the problems of affecting the life and performance of leds, and the cooling efficiency is still not enough for high power/watt leds, so as to facilitate lateral air convection, reduce the overall weight of the cooling module, and increase the cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

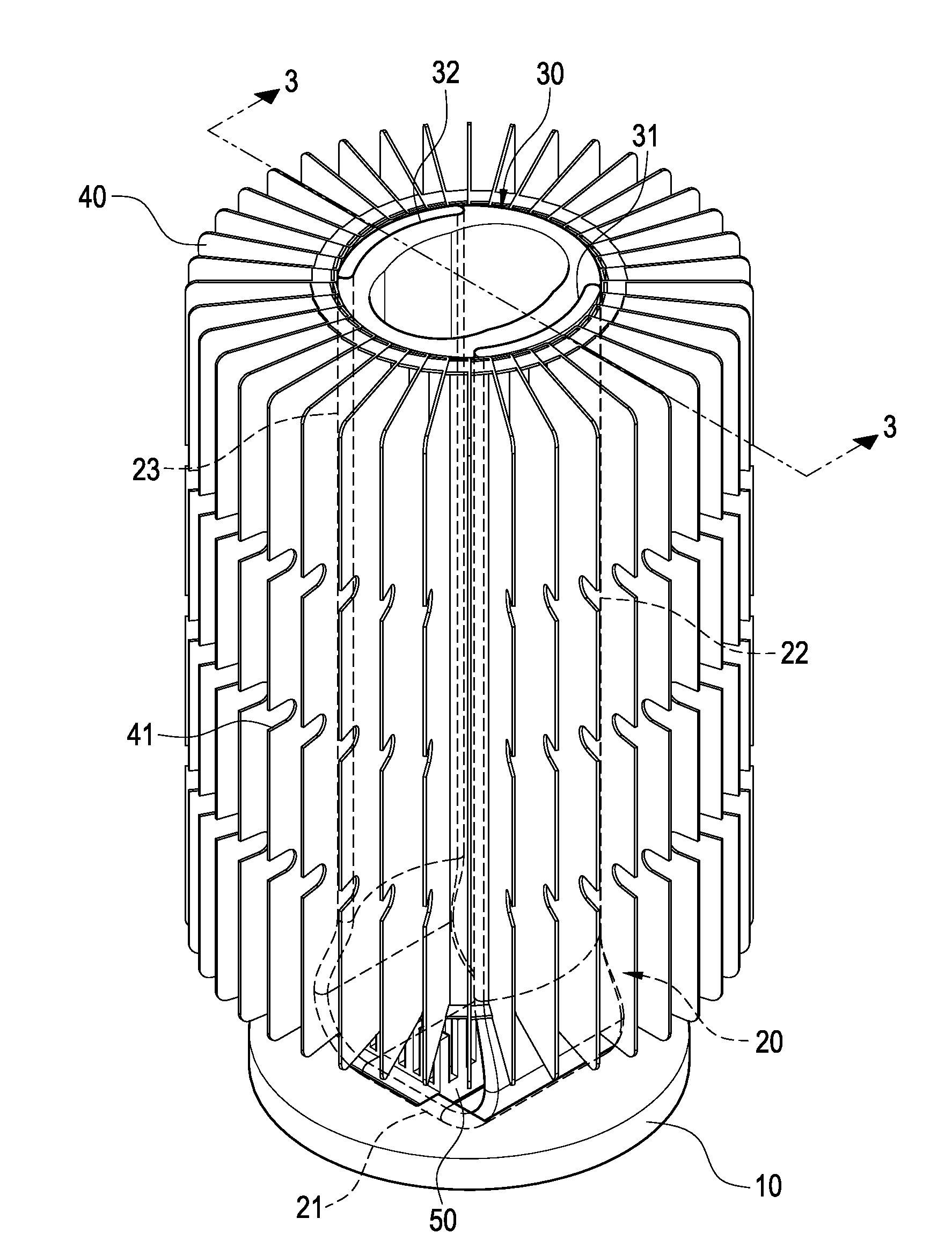

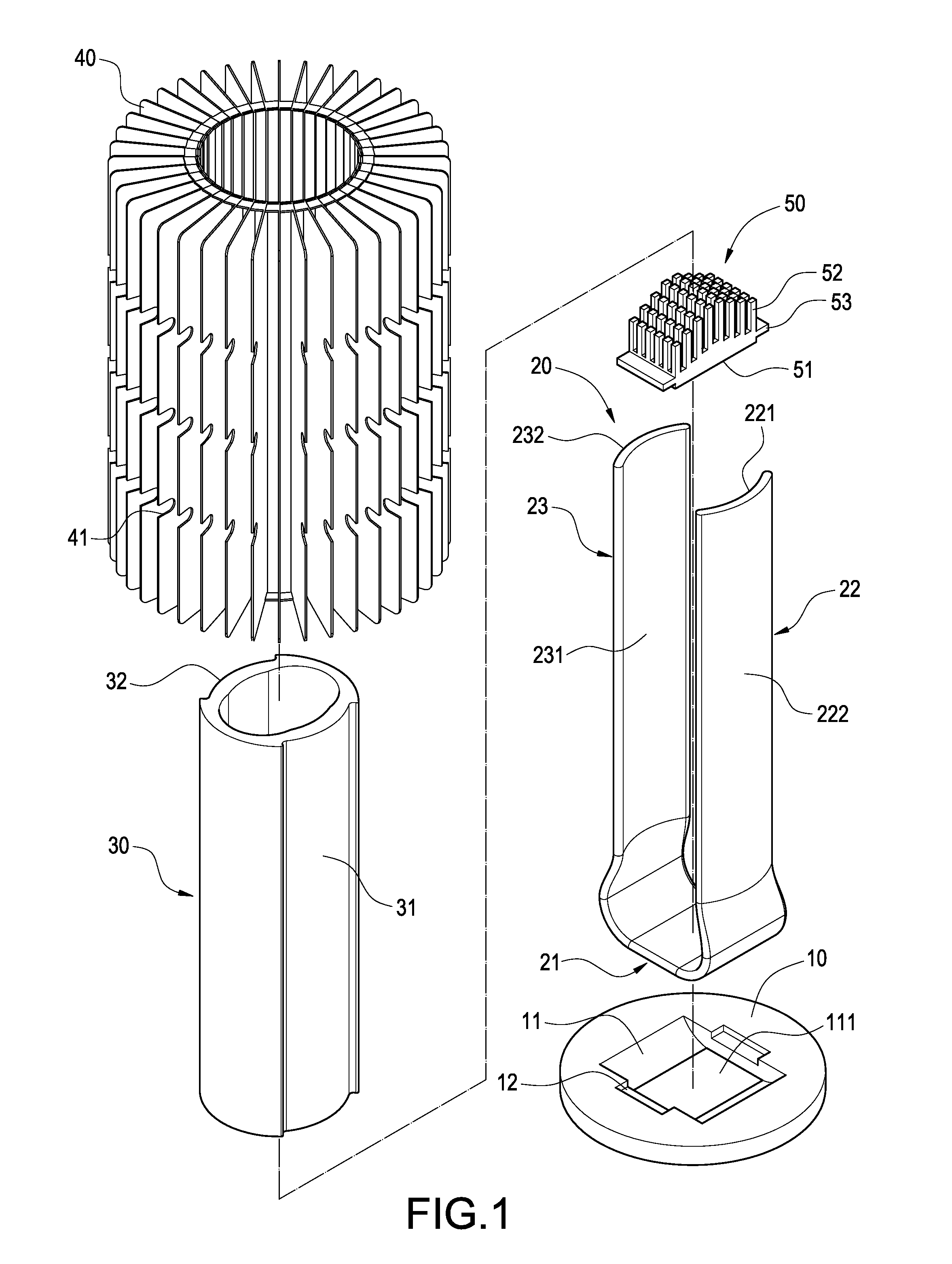

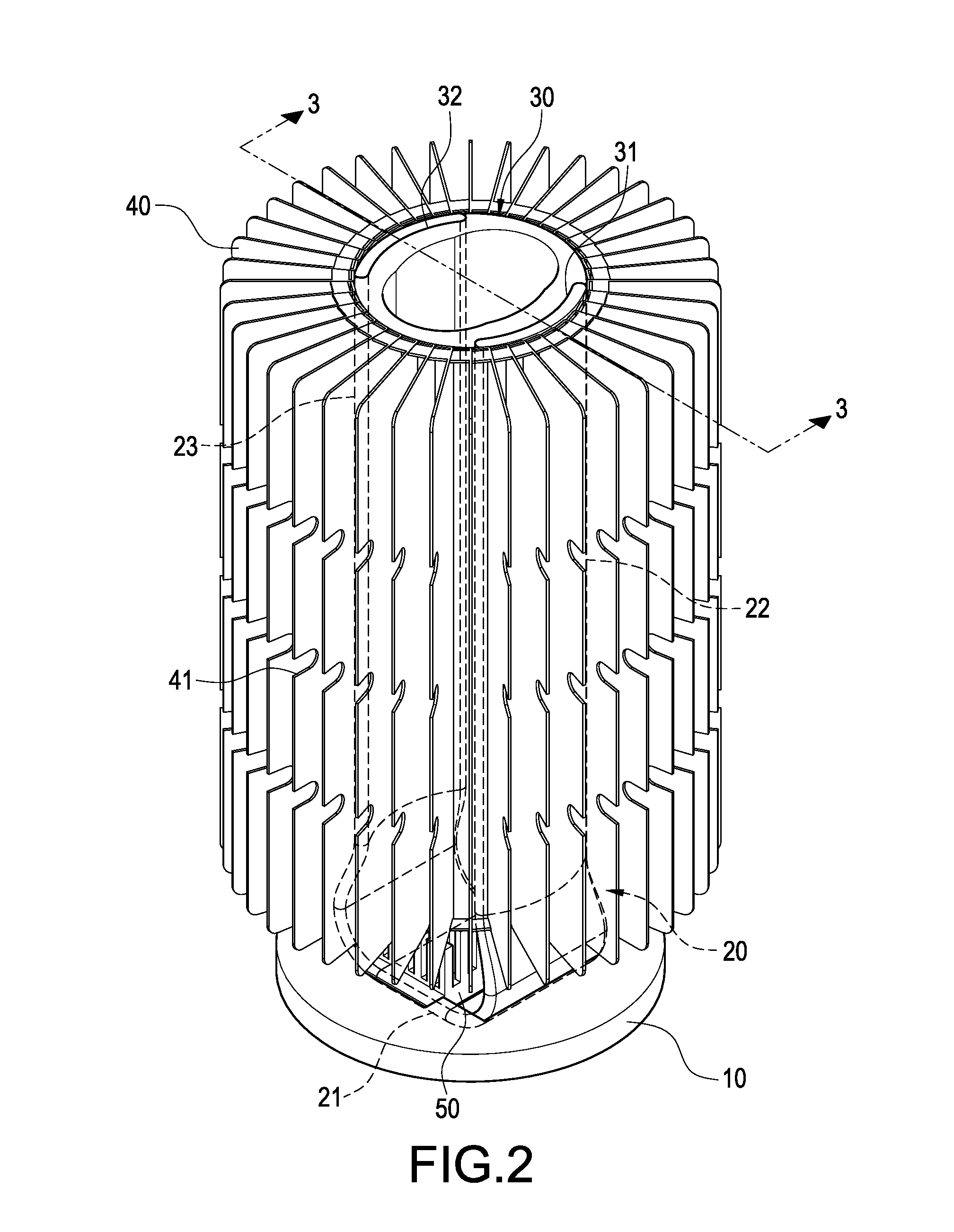

[0016]FIG. 1 to FIG. 4 shows a cooling module for an LED lamp according to an embodiment of the present invention. The cooling module of the embodiment primarily includes a heat conducting base 10, a thermostatic plate 20, a hollow column 30, and a plurality of cooling fins 40.

[0017]The heat conducting base 10 is made of metal such as aluminum, copper, or their alloy. Generally, the shape of the heat conducting base 10 is like a circular plate. A middle part of the plate has a rectangular container trough 11. A through opening 111 is formed on the bottom of the container trough 11. A step 12 is set on each of the two lateral sides of the container trough 11.

[0018]The thermostatic plate 20 of this embodiment is a vapor chamber, the vacuum chamber of which contains components such as capillary structure and working fluid. The gas-liquid phase change of the working fluid can achieve heat conduction. Furthermore, the capillary structure can help the working fluid to flow-back and hence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com