System and Method for Recovery of Nickel Values From Nickel-Containing Ores

a nickel-containing ores and nickel-based technology, applied in the field of systems and methods for recovering nickel values, can solve the problems of many existing methods and implementation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

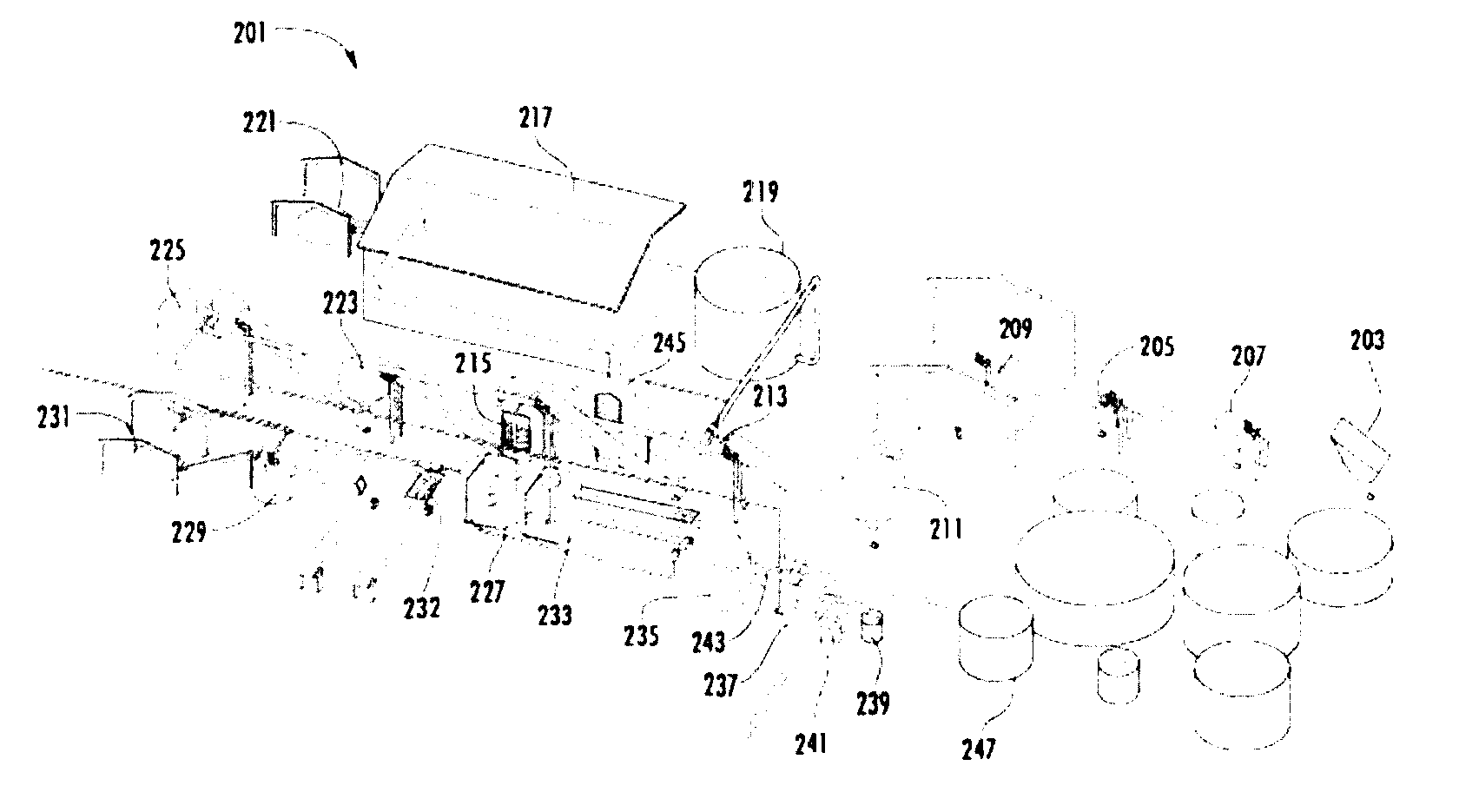

[0015]While the methods currently known to the art for recovering nickel values from ore feedstocks may be useful in certain applications, a need exists in the art for further improvements in these methods. In particular, it is found that some of these methods leave significant concentrations of nickel in the treated ore, especially when the ore being treated is a nickel laterite. Other methods, such as the Mond process, require the ore to undergo preliminary processing, and hence are not suitable for application to raw ore feedstocks. Still other methods are limited in that they do not provide for the efficient co-extraction of nickel with other metal values, such as scandium and cobalt; since these values frequently occur in commercially significant levels in many nickel laterite ores, the use of such methods diminishes the return on investment of the mining operation.

[0016]Finally, some of the processes currently utilized in the art for the extraction of metal values from nickeli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| soluble | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com