Turbine or compressor blade

a turbine blade and compressor technology, applied in the field of blades, can solve the problems of disadvantageous comparatively low stability in relation to pressure loading, and achieve the effects of reducing co2 development, reducing energy input, and being resistant and durabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

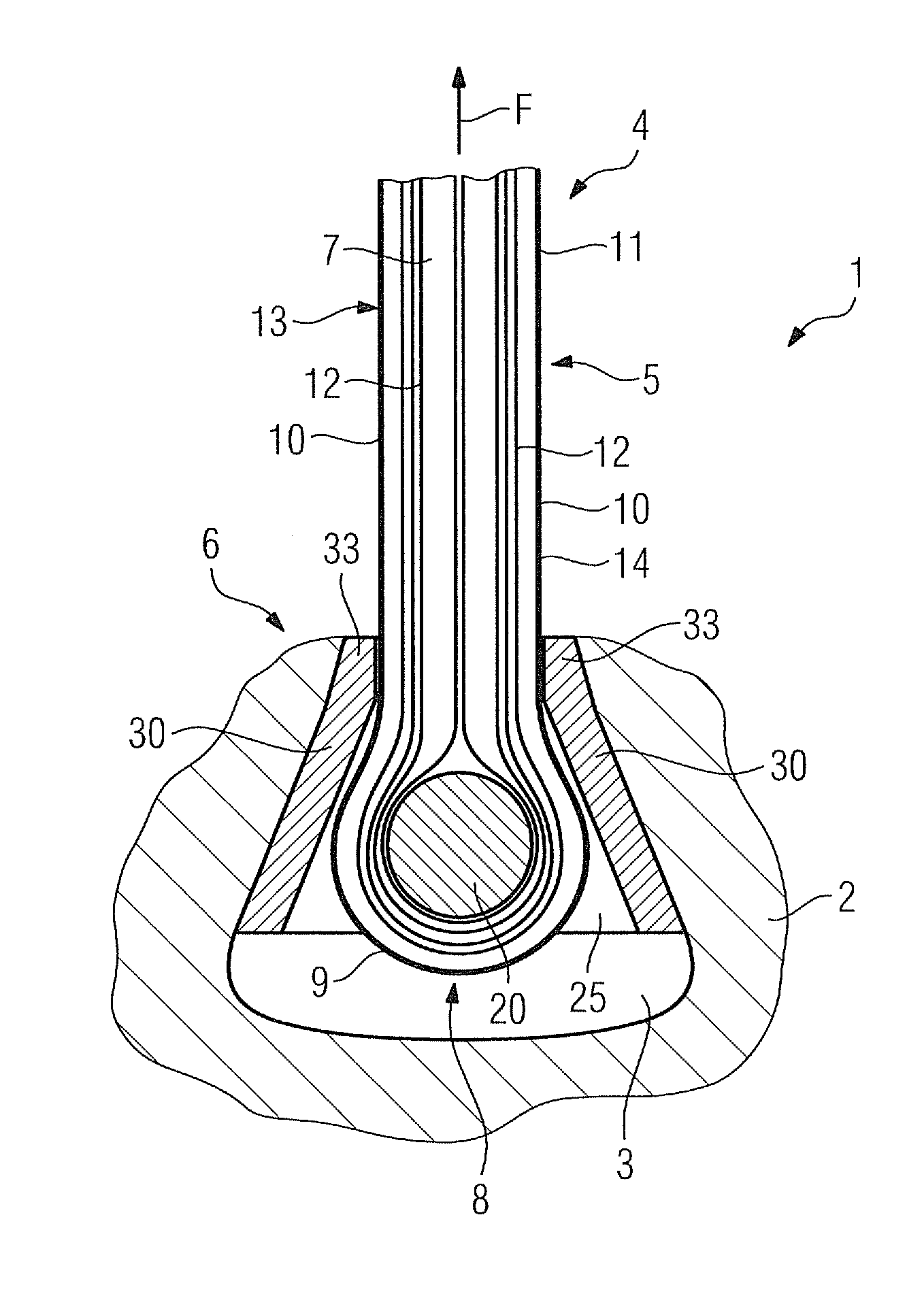

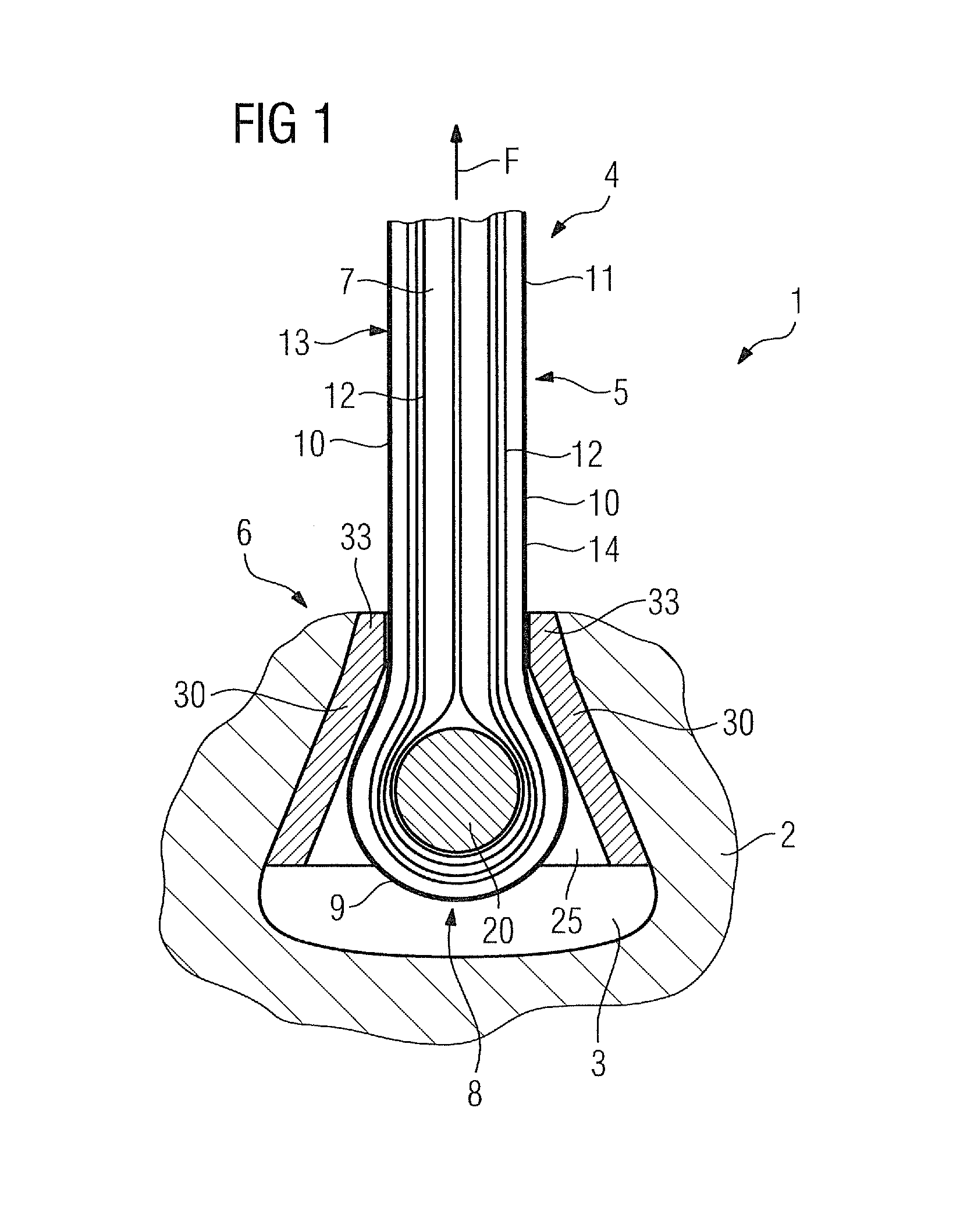

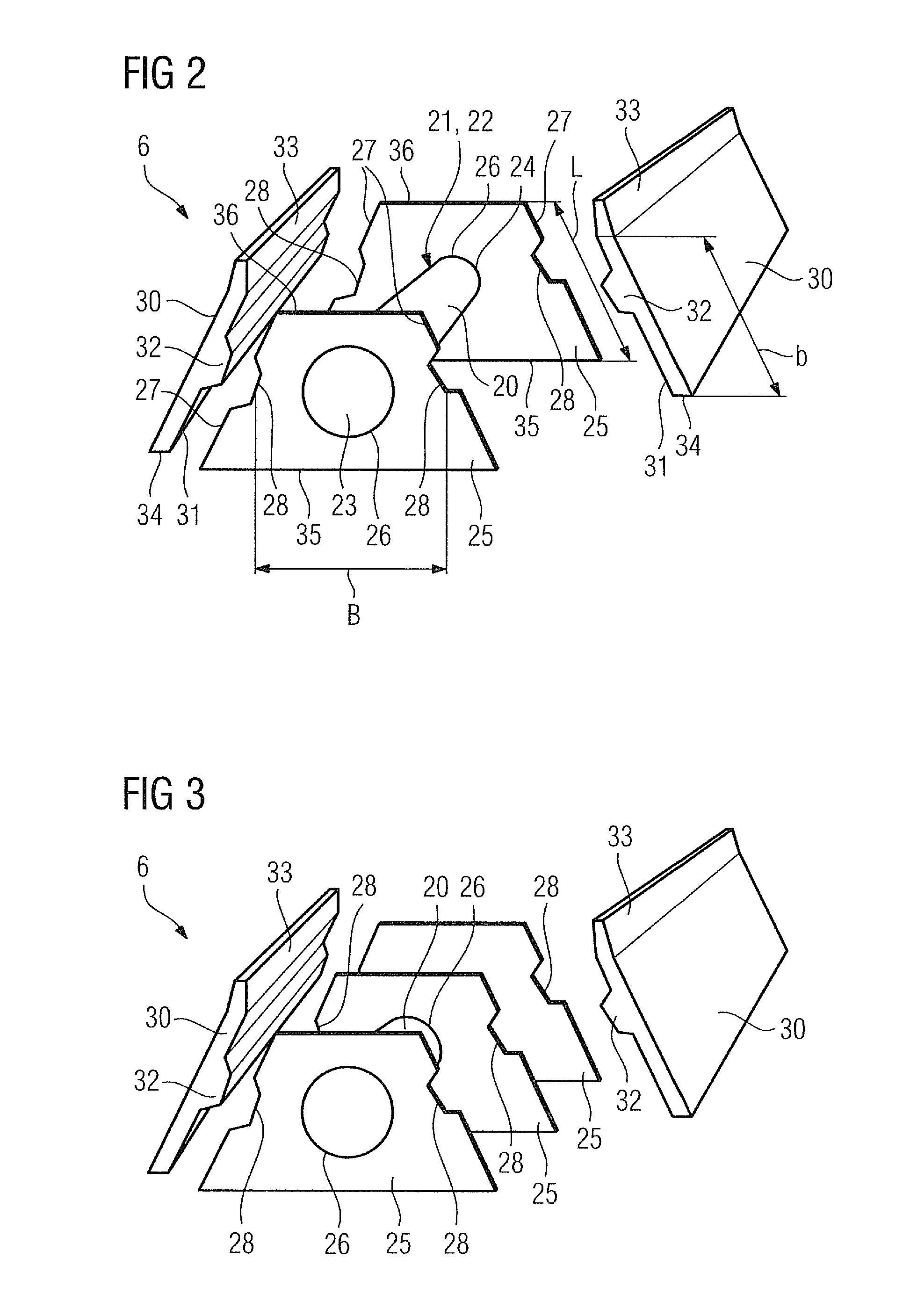

[0035]FIG. 1 shows a turbine rotor assembly 1 in a slightly schematized sectional view. The turbine rotor assembly 1 comprises a rotor 2 consisting of high-grade steel, into which a multiplicity of axial grooves 3 are introduced in a uniform distribution over the circumference. In FIG. 1, only a detail of the rotor 2 in the region of a single axial groove 3 is shown. In the first embodiment which is shown here, each axial groove 3 is essentially constructed as a so-called dovetail groove.

[0036]A turbine blade 4 is accommodated in the axial groove 3. The turbine blade 4 comprises a blade airfoil 5 (only partially shown here), and a blade root 6 which serves for anchoring the turbine blade 4 in the axial groove 3.

[0037]The blade airfoil 5 is produced from a plurality of layered webs 7 consisting predominantly of unidirectional CFK laminated fabric. The webs 7 in this case are folded in such a way—preferably approximately in the middle—that in the region of the fold 8, which results du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com