Control of fluid flow during treatment of subterranean sites using well fluid injection

a technology of fluid flow and subterranean sites, applied in fluid removal, chemistry apparatus and processes, borehole/well accessories, etc., can solve problems such as reducing the sweep efficiency of water, and achieve the effect of improving oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Prophetic

To Determine Breakthrough Times in Production Wells

[0033]The breakthrough time for each production well is determined using a tracer chemical such as a sodium salt of Fluorescein dye, commonly known as Uranine (CAS 518-47-8, Part number A833-500, Fisher Scientific, 2000 Park Lane Drive, Pittsburgh, Pa. 15275).

[0034]Uranine (2.7 kilogram, kg) is added to a tank containing 9,000 L of water. The normal flow of injection water to the injection well to be tested is shut off. The Uranine treated water is injected over a 7.2 hours (h) period into the injection well at a rate of injection equal to 1,250 L / h which is the normal injection flow rate. Upon completion of the injection of the 9,000 L of Uranine solution, the normal injection flow of water is restored at the normal injection rate of 30,000 L / D. After the start of Uranine injection, samples are taken from the associated production wells at various time intervals for example, 6, 12, 18, 24, 36, 48 h following initial tracer...

example 2

Prophetic

To Inoculate a Subterranean Site without Loss of Microbial Inoculum

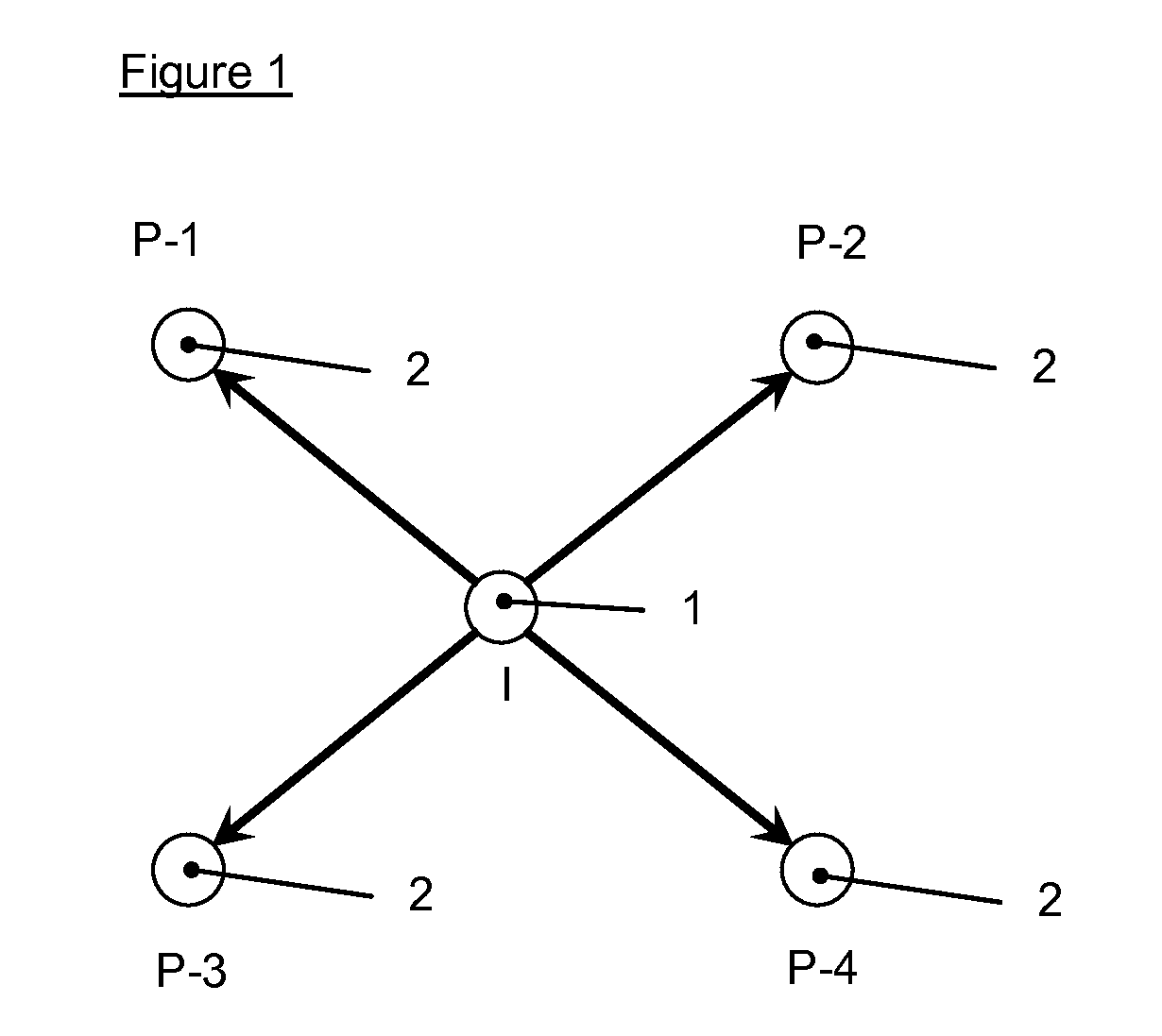

[0035]In this example, the injection and production wells of a subterranean site are arranged in an inverted five spot pattern as shown in FIG. 1. For the purposes of this example, it is assumed that production well P2 has the shortest breakthrough time followed by production well P4 with the second shortest breakthrough time. A microbial inoculum suspension is prepared by making in a 6,000 L tank a nutritional chemical fluid appropriate for the particular microorganism used. A microbial inoculum is then added to the nutritional chemical fluid to produce a suspension at the desired concentration of microbes and nutrients.

The following steps are then taken:

1) Shut off the normal injection water flow into injection well.

2) Inject the inoculum suspension into the injection well at the normal injection rate for the injection well (i.e., 1,250 L / h for 4.8 h)

3) After start of injection of inoculum into the injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com