Polishing method, manufacturing method of piezoelectric vibrating piece, piezoelectric vibrator, oscillator, electronic apparatus and radio-controlled timepiece

a manufacturing method and piezoelectric technology, applied in the field of polishing methods, can solve the problems of inability to enhance the thickness accuracy the method is not applicable to the polishing so as to achieve the enhancement of the rotational balance of the carrier in rotation and revolution, the reduction of irregular thickness of the tuning fork forming wafer among the plurality of carriers, and the reduction of the thickness of the tuning fork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]Hereinafter, the explanation is made with respect to a polishing method, a manufacturing method of a piezoelectric vibrating piece, a piezoelectric vibrator having a piezoelectric vibrating piece manufactured by the manufacturing method of a piezoelectric vibrating piece, an oscillator having the piezoelectric vibrator, an electronic apparatus, and a radio-controlled timepiece according to one embodiment of the present invention.

[0051]Hereinafter, embodiments of the present invention are explained in conjunction with drawings.

(Piezoelectric Vibrator)

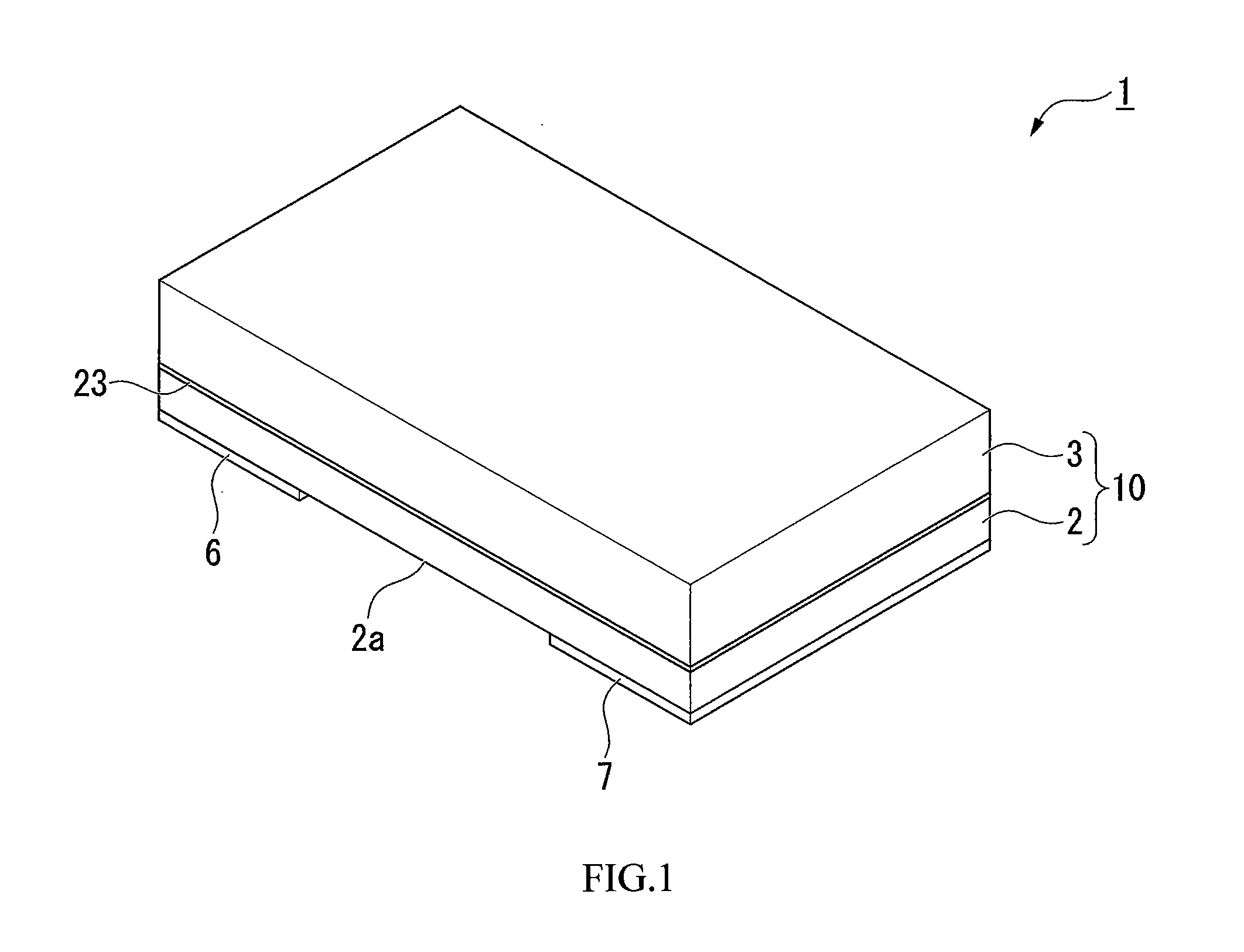

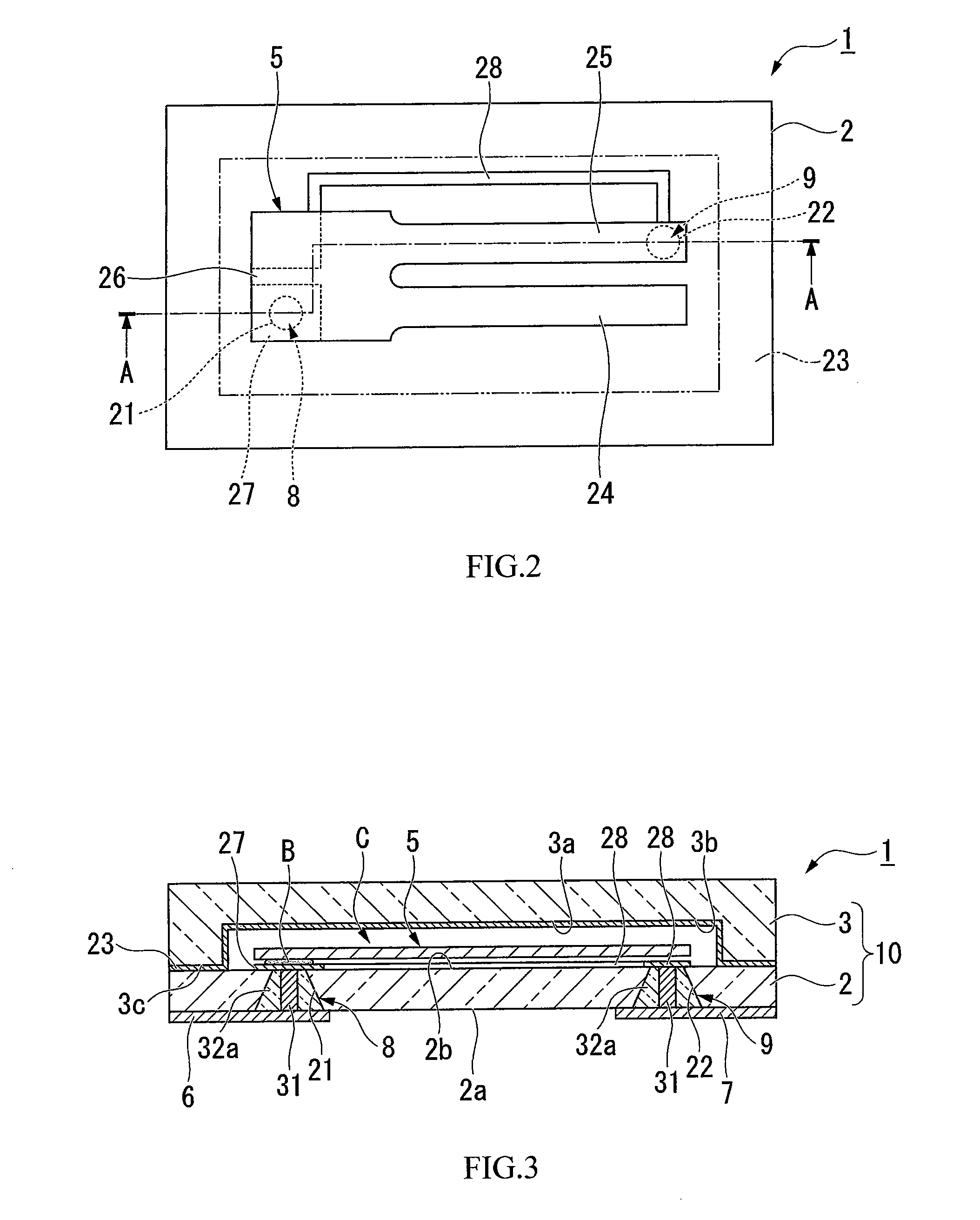

[0052]FIG. 1 is an appearance perspective view of a piezoelectric vibrator according to this embodiment as viewed from a lid substrate side. FIG. 2 is an internal constitutional view of the piezoelectric vibrator, and is also a view of a piezoelectric vibrating piece as viewed from above in a state where the lid substrate is removed.

[0053]Further, FIG. 3 is a cross-sectional view of the piezoelectric vibrator taken along a line A-A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com