Apparatus and method for UV treatment, chemical treatment, and deposition

a technology of uv treatment and apparatus, applied in the direction of liquid surface applicators, coatings, chemical vapor deposition coatings, etc., can solve the problems of significant process integration challenges and the increase of the cost of ownership of the restoration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]Embodiment of the present invention generally relates to apparatus and for processing a substrate. More particularly, embodiments of the present invention provide apparatus and methods for performing UV treatment and chemical treatment and / or deposition in the same chamber.

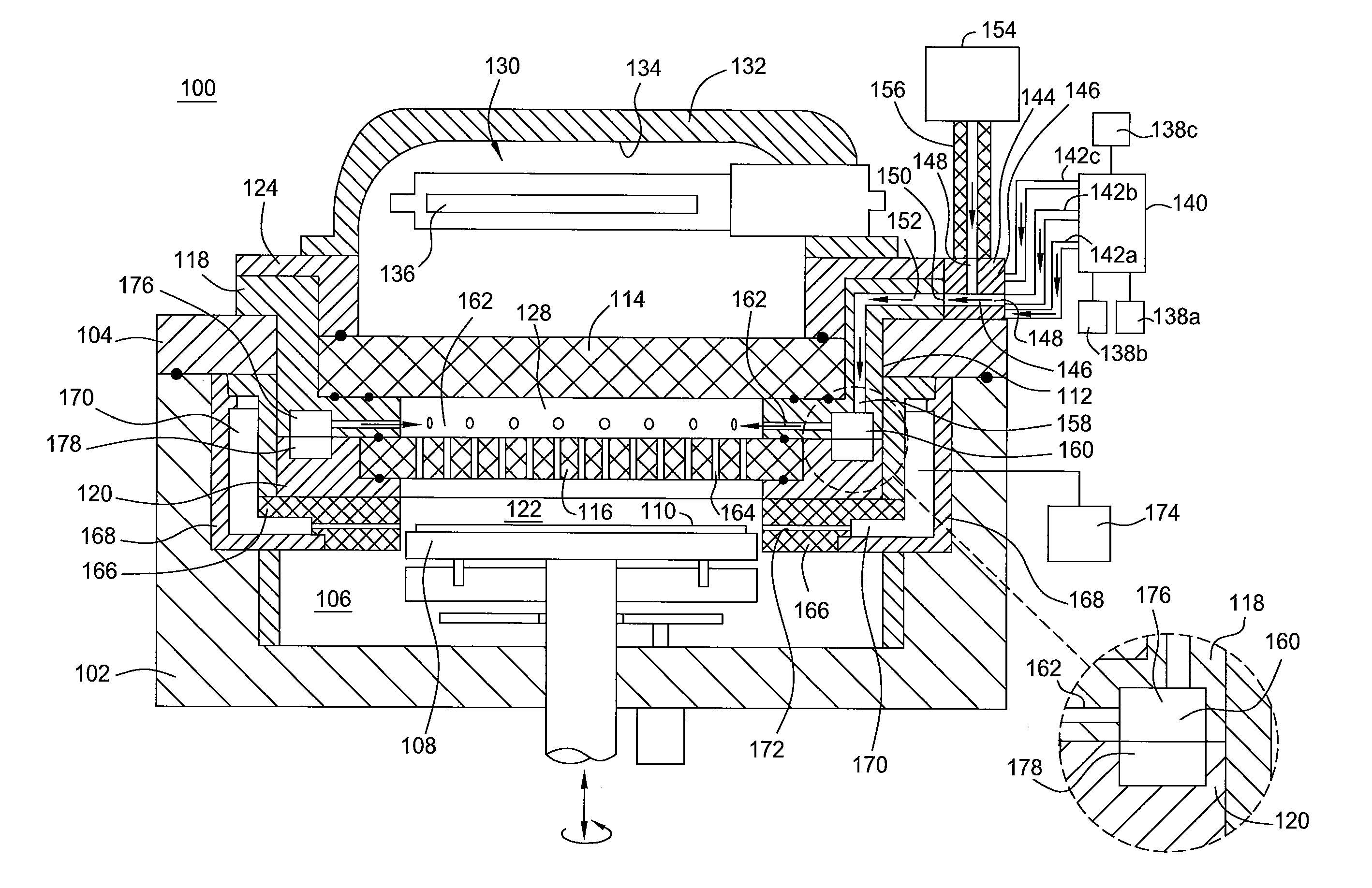

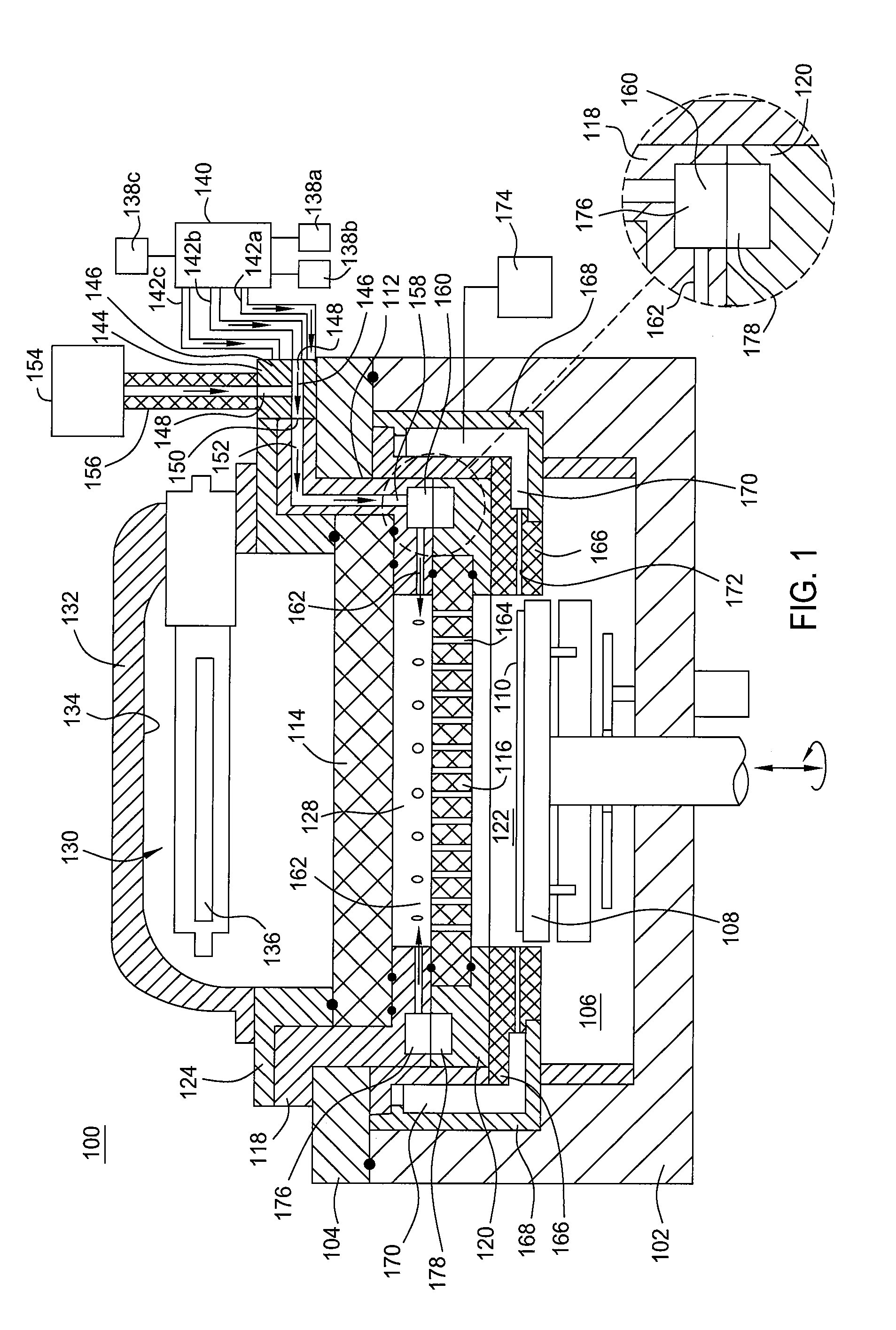

[0027]FIG. 1 is a schematic sectional view of a processing chamber 100 according to one embodiment of the present invention. The processing chamber 100 is configured to processing a substrate using UV energy, one or more processing gases, and remotely generated plasma.

[0028]The processing chamber 100 includes a chamber body 102 and a chamber lid 104 disposed over the chamber body. The chamber body 102 and the chamber lid 104 form an inner volume 106. A substrate support assembly 108 is disposed in the inner volume 106. The substrate support assembly 108 receives and supports a substrate 110 thereon for processing.

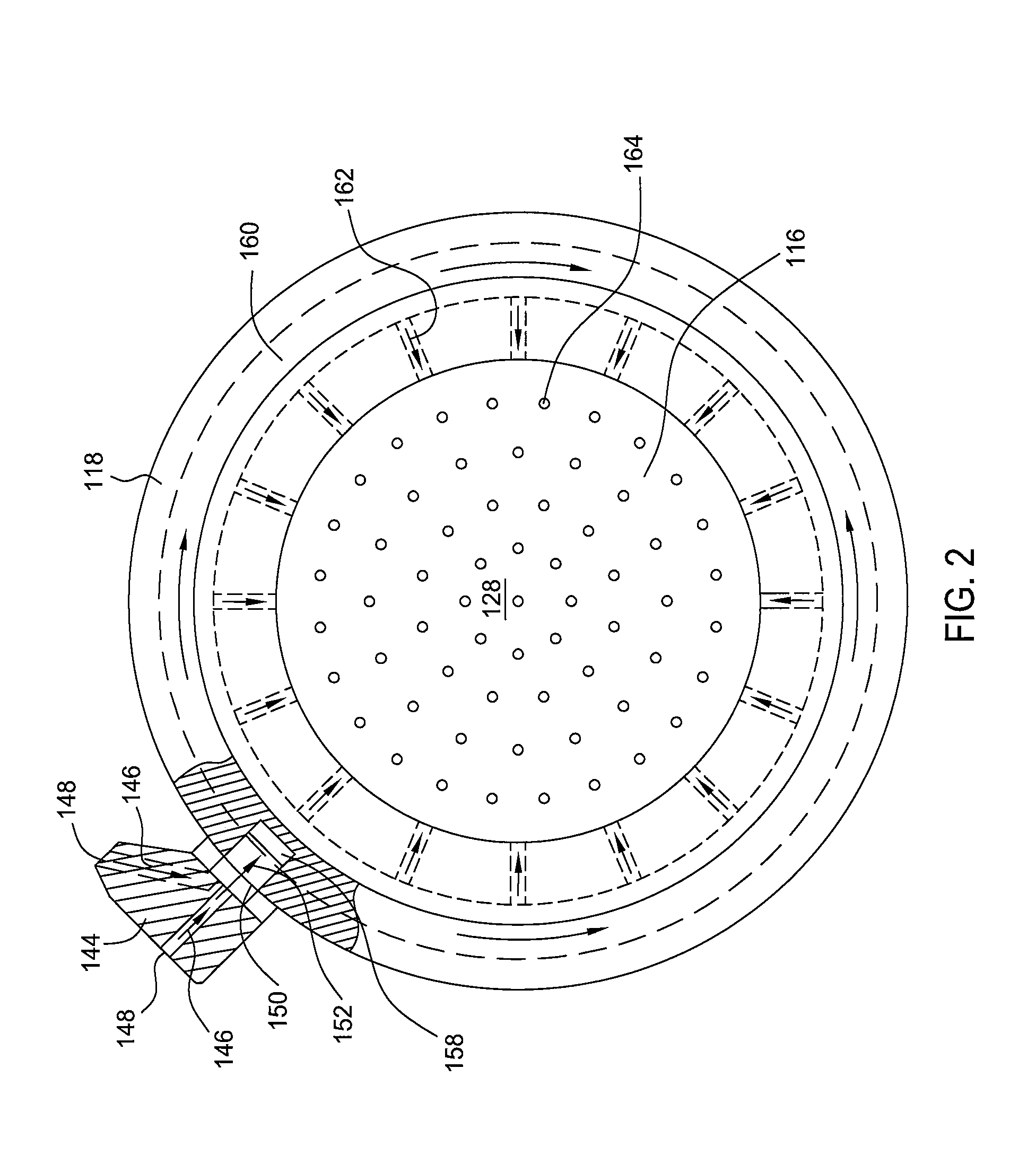

[0029]A UV transparent gas distribution showerhead 116 is hung in the inner volume 106 through a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric constant | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com